*** START OF THE PROJECT GUTENBERG EBOOK 49675 ***

The cover image was created by the transcriber and is placed in the public domain.

[Pg i]

THE THOUGHT IS IN THE QUESTION THE INFORMATION IS IN THE ANSWER

HAWKINS

ELECTRICAL GUIDE

NUMBER

FIVE

QUESTIONS

ANSWERS

&

ILLUSTRATIONS

A PROGRESSIVE COURSE OF STUDY

FOR ENGINEERS, ELECTRICIANS, STUDENTS

AND THOSE DESIRING TO ACQUIRE A

WORKING KNOWLEDGE OF

ELECTRICITY AND ITS APPLICATIONS

A PRACTICAL TREATISE

by

by

HAWKINS AND STAFF

THEO. AUDEL & CO. 72 FIFTH AVE. NEW YORK.

[Pg ii]

COPYRIGHTED, 1914,

BY

THEO. AUDEL & CO.,

New York.

Printed in the United States.

[Pg iii]

TABLE OF CONTENTS

GUIDE NO. 5.

| ALTERNATING CURRENTS |

997 to 1,066 |

| The word

"alternating"—advantages of

alternating current—direct current apparatus;

alternating current apparatus—disadvantages

of alternating current—alternating

current principles—the

sine—application and construction of the sine

curve—illustrated definitions:

cycle, alternation, amplitude, period, periodicity,

frequency—commercial frequencies—advantages

of low frequency—phase—phase

difference—phase displacement—synchronism—"in

phase"—curves illustrating "in phase" and "out of

phase"—illustrated definitions:

in phase; in quadrature, current leading; in quadrature,

current lagging; in opposition—maximum

volts and amperes—average volts

and amperes—elementary alternator developing one

average volt—virtual volts and

amperes—effective volts and

amperes—relation between shape of wave and form

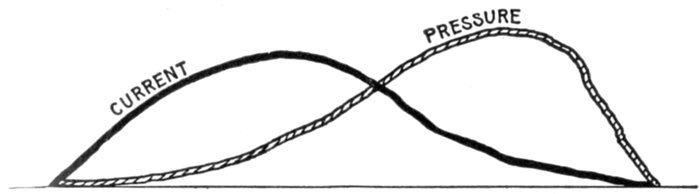

factor—wave form—oscillograph wave

form records—what determines wave form—effect

of one coil per phase per pole—single phase

current; hydraulic analogy—two

phase current; hydraulic analogy—two

phase current distribution—three

phase current; hydraulic analogy;

distribution—inductance—the

henry—inductive and non-inductive

coils—hydraulic analogy of inductance—inductance

coil calculations—ohmic value of

inductance—capacity:

hydraulic analogy—the farad—specific inductive

capacity—condenser connections—ohmic

value of capacity—lag and

lead—mechanical analogy of lag—lag

measurement—steam engine analogy of current flow at zero

pressure—reactance—examples—choking

coil—impedance

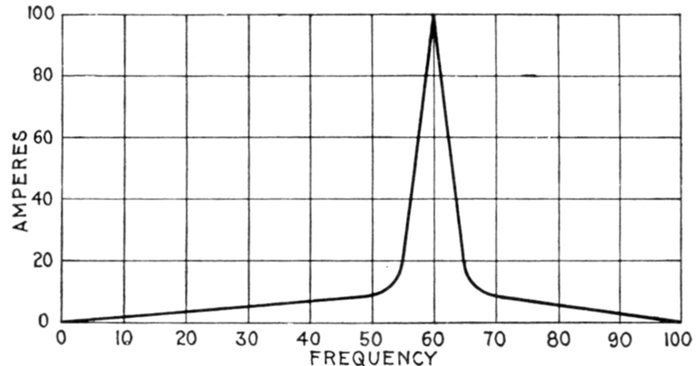

curve—resonance—critical

frequency—skin effect.[Pg iv] |

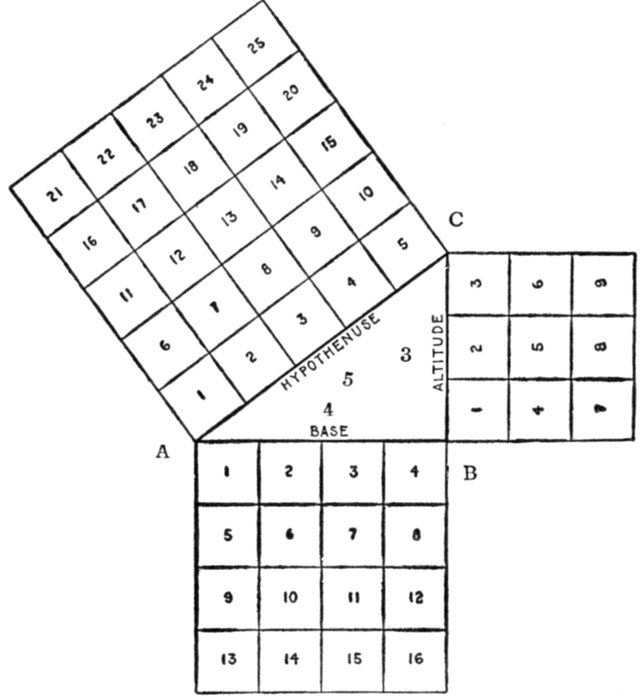

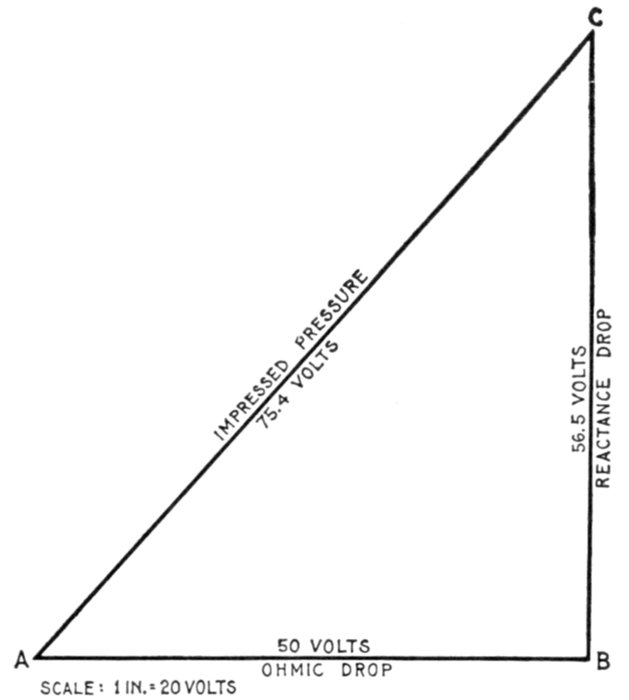

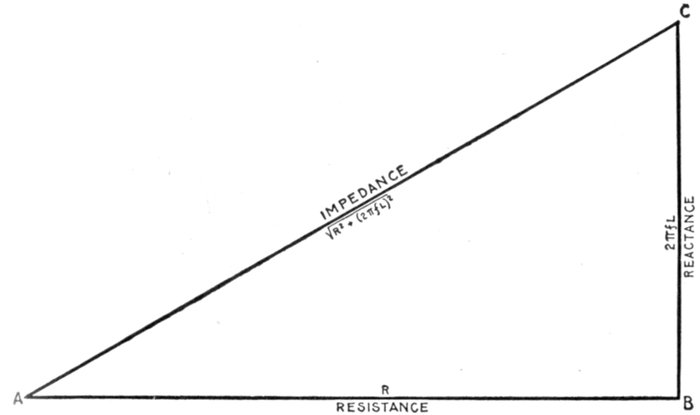

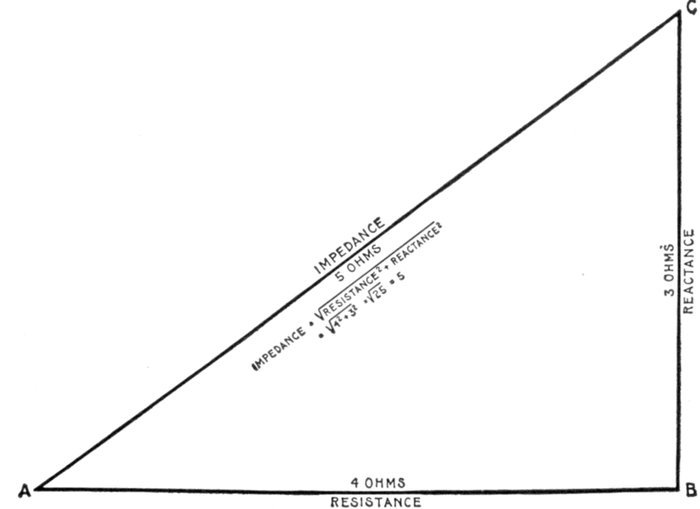

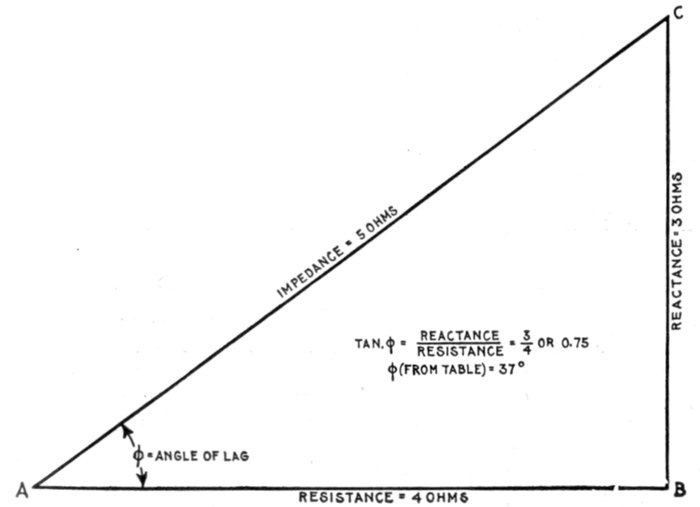

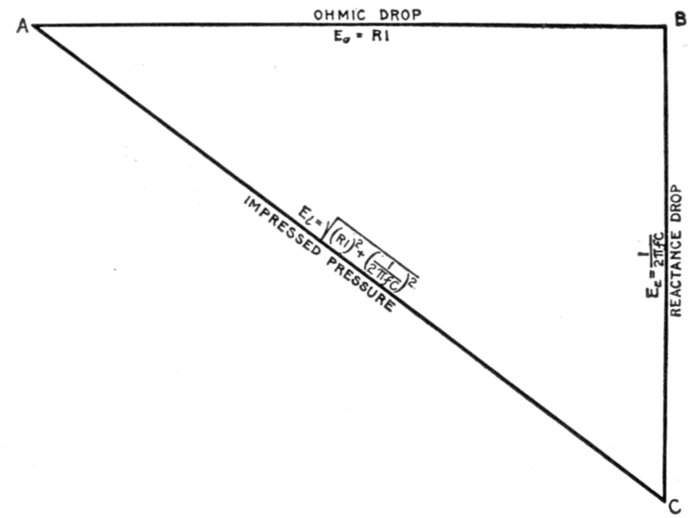

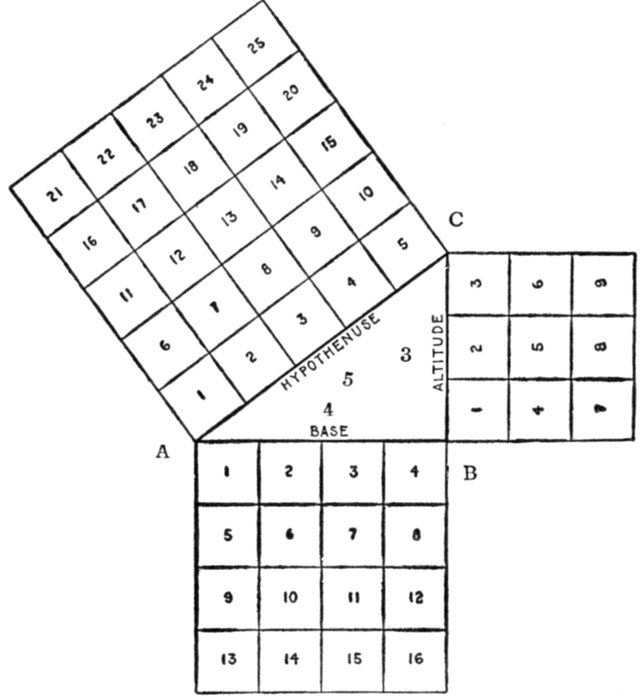

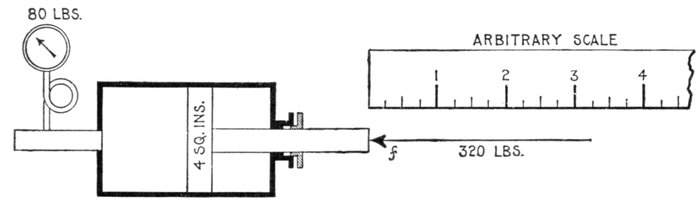

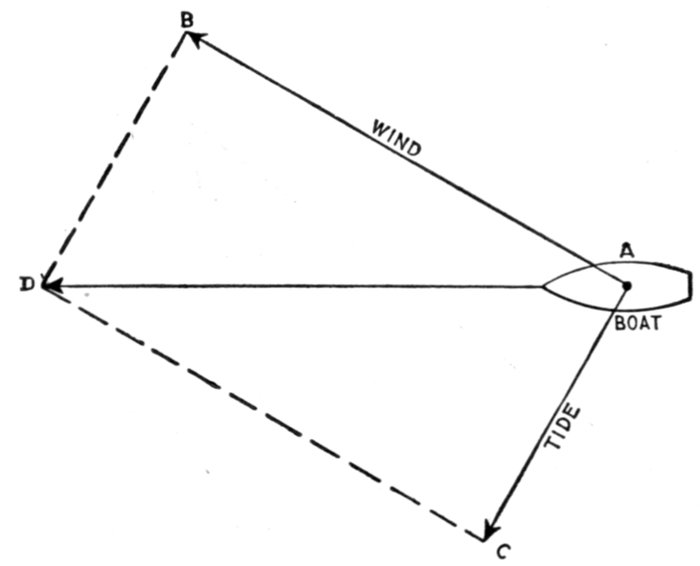

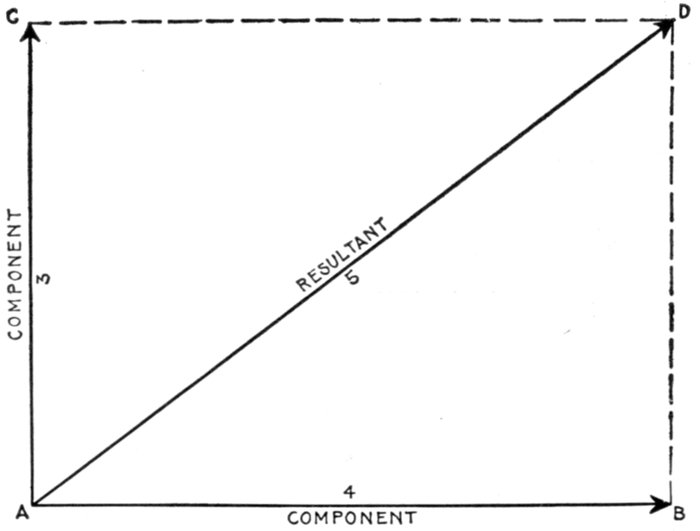

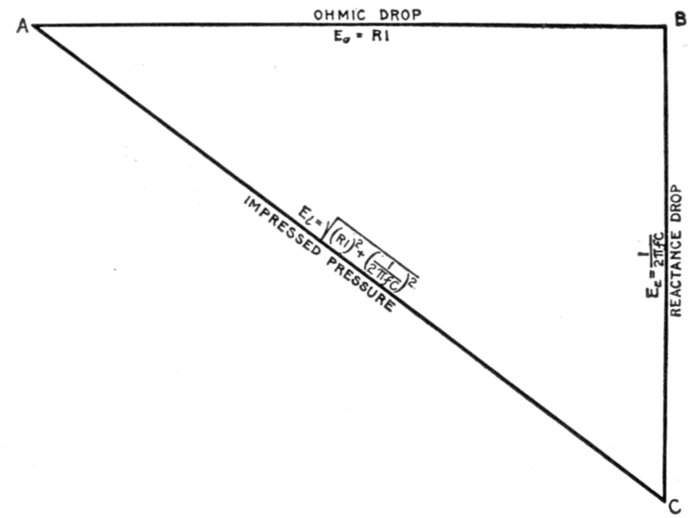

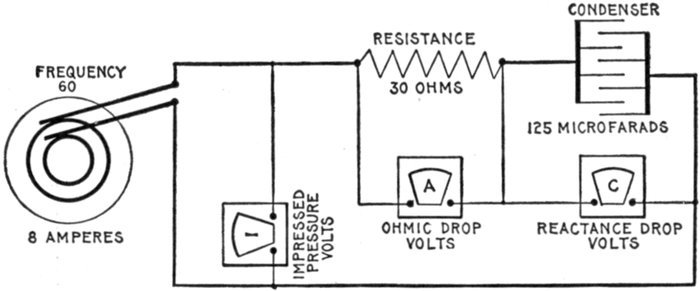

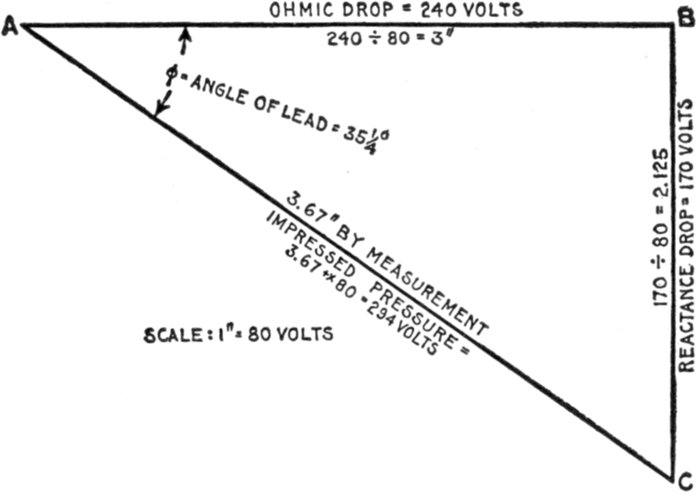

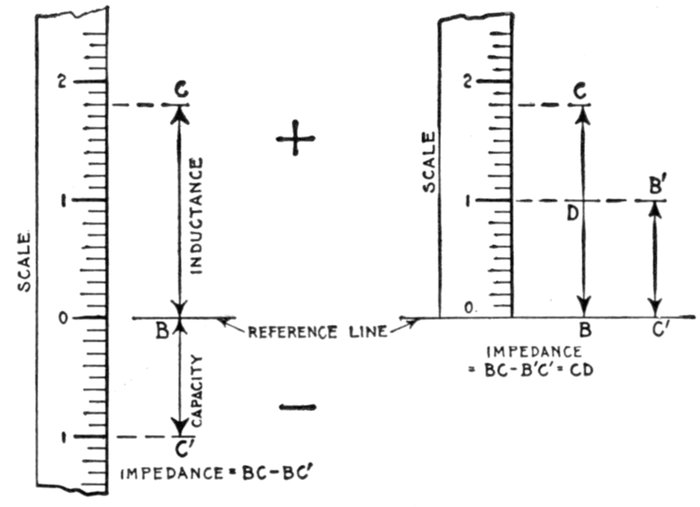

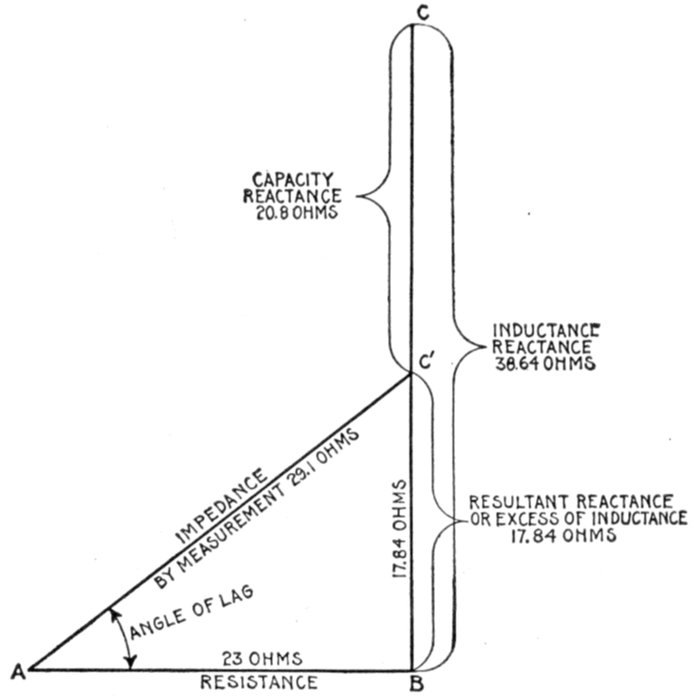

| ALTERNATING CURRENT DIAGRAMS |

1,067 to 1,100 |

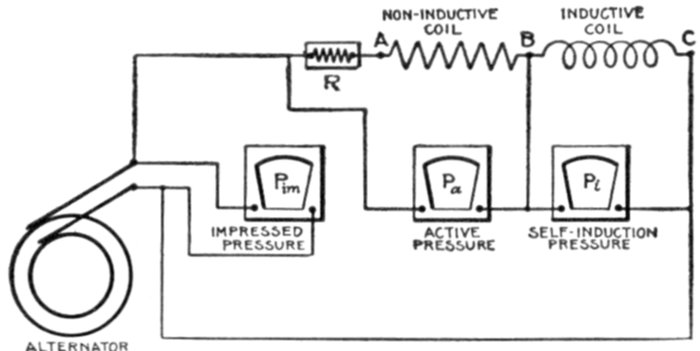

| Definitions: impressed

pressure, active pressure, self-induction pressure,

reverse pressure of self-induction—rate

of change in current strength—properties

of right angle triangles—equations of the

right triangle—representation of forces by

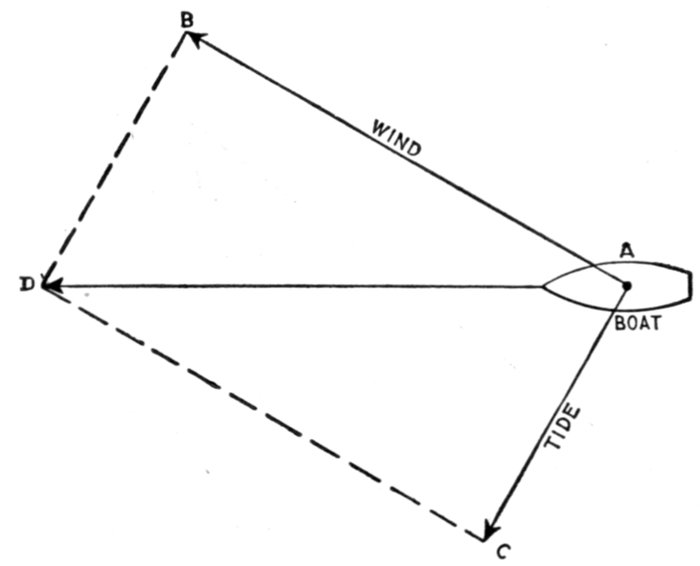

wires—parallelogram of forces; the

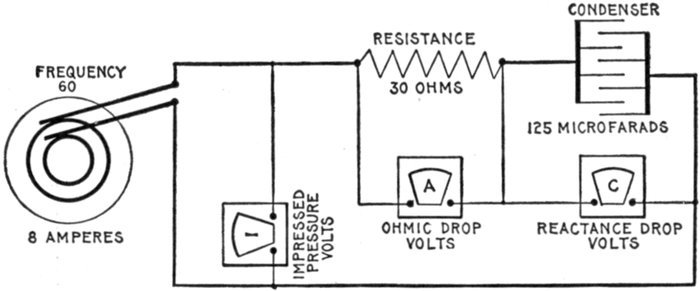

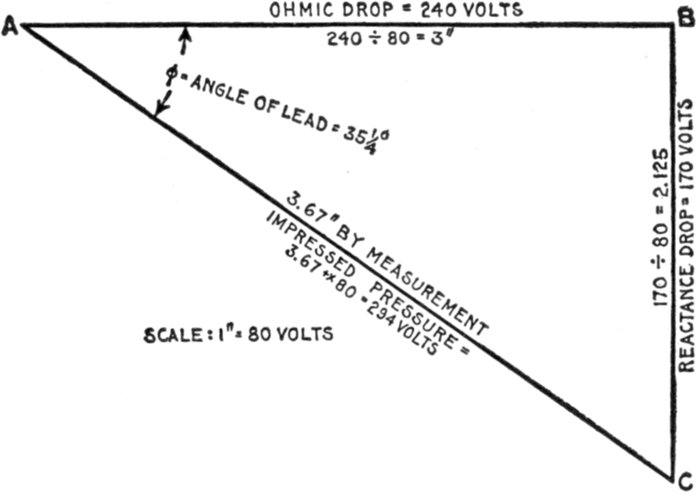

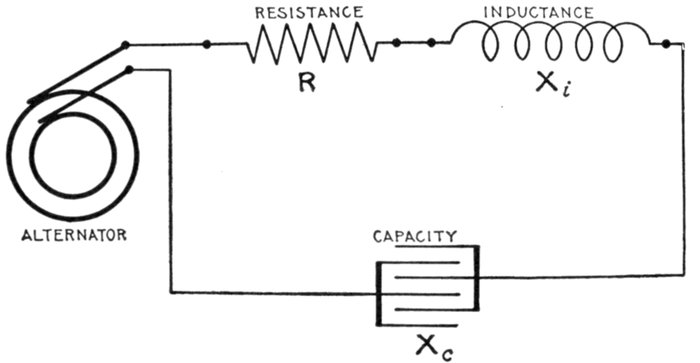

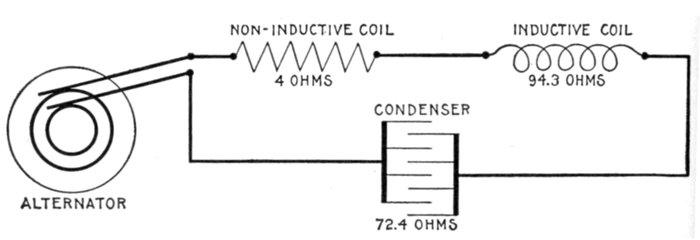

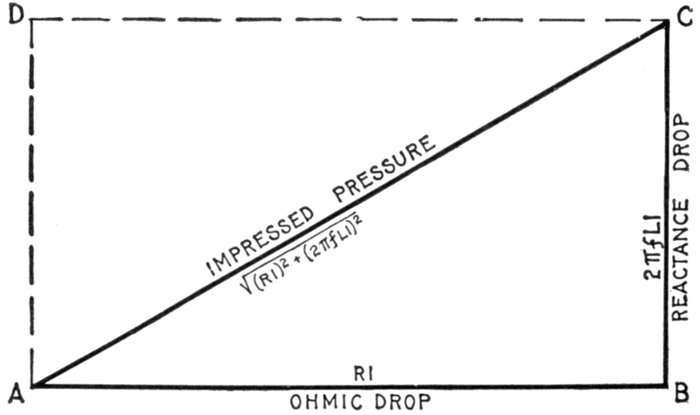

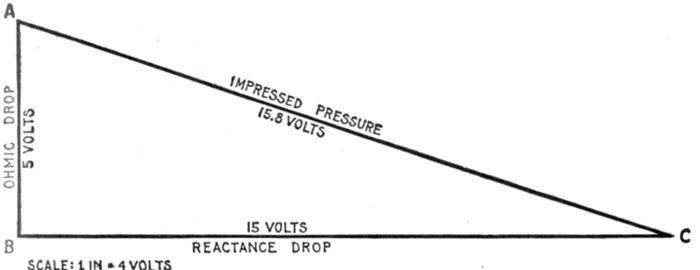

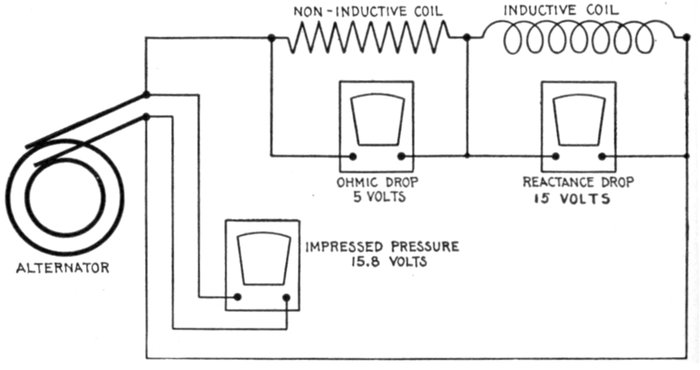

resultant—circuits containing resistance

and inductance—graphical method of obtaining

the impressed pressure—equations for ohmic drop

and reactance drop—examples—diagram

for impedance, angle of lag, etc.—circuits

containing resistance and capacity—capacity

in series, and in parallel—amount of lead—action

of condenser—the condenser pressure—capacity

pressure—equation for impedance—- examples and

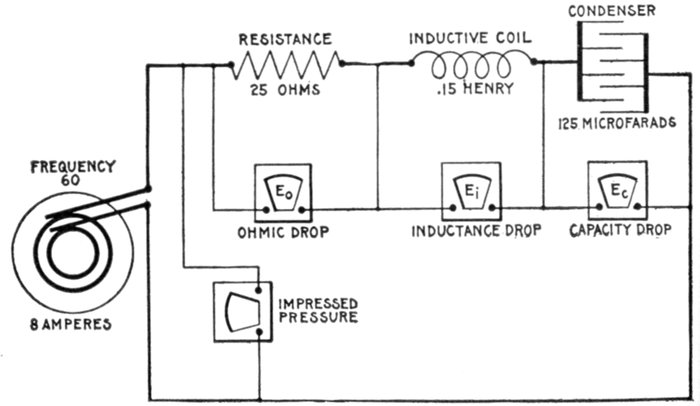

diagrams—circuits containing resistance,

inductance, and capacity—impedance

equation—examples and diagrams—equation for

impressed pressure—examples and diagrams. |

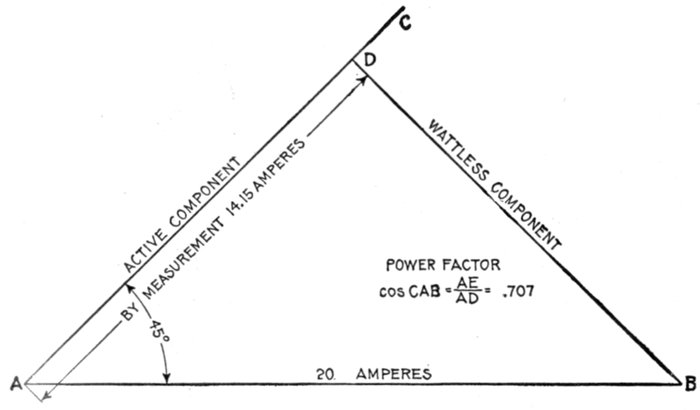

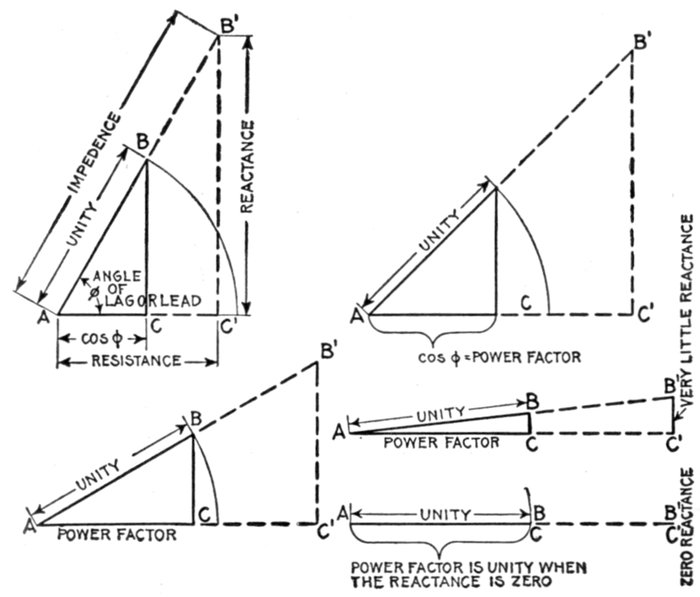

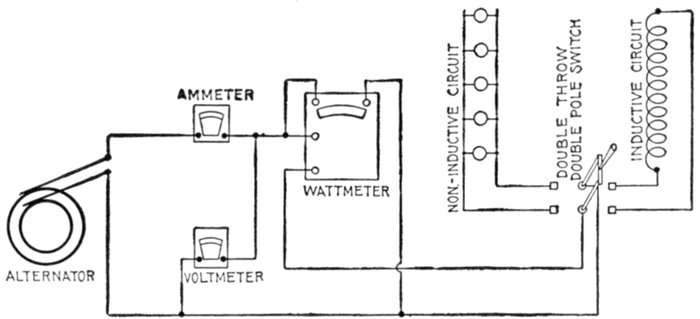

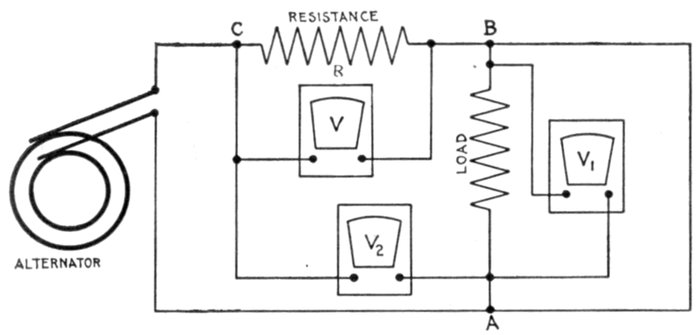

| THE POWER FACTOR |

1,101 to 1,124 |

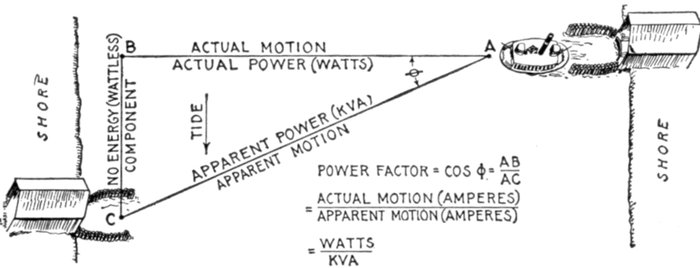

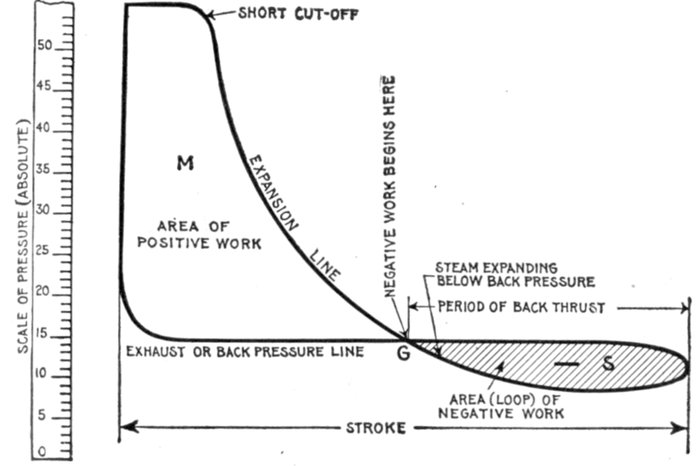

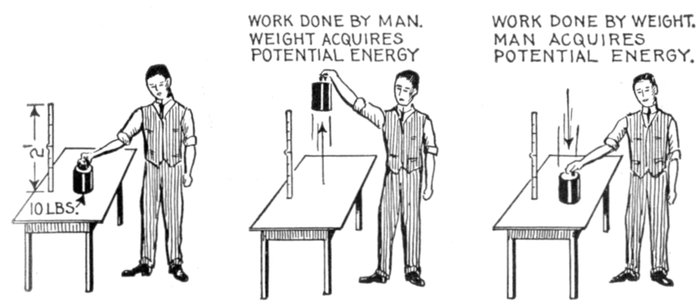

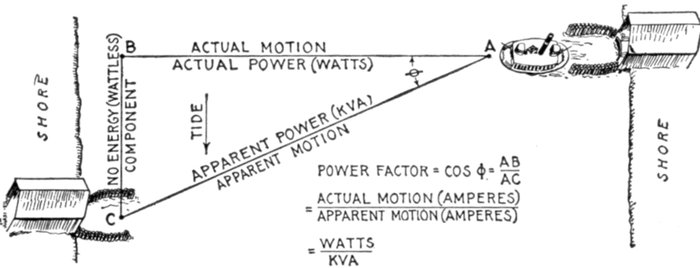

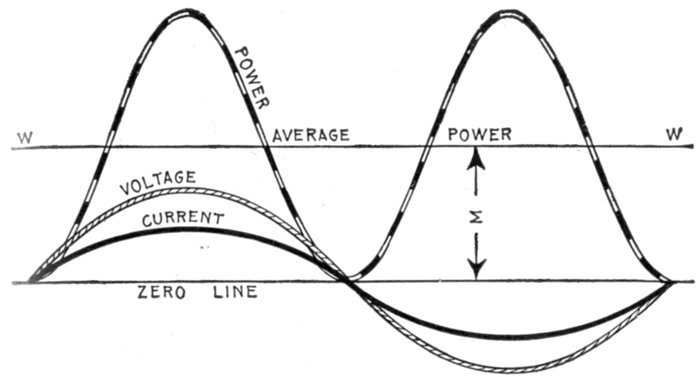

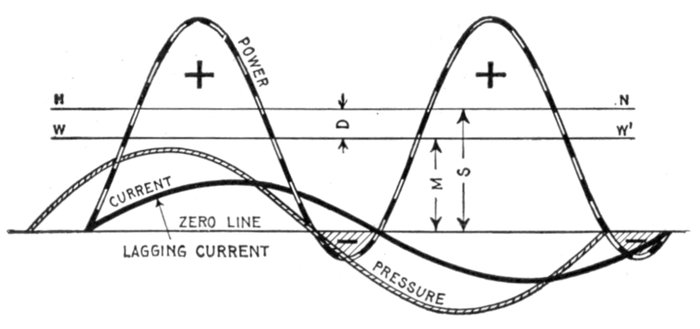

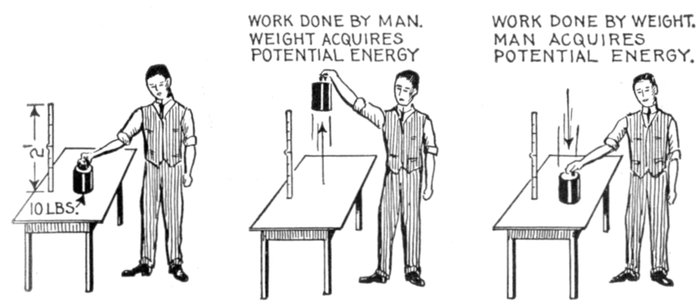

| Definition of power factor—true

watts—- apparent watts—ferry boat

analogy of power factor—limits of power

factor—effect of lag or lead—how

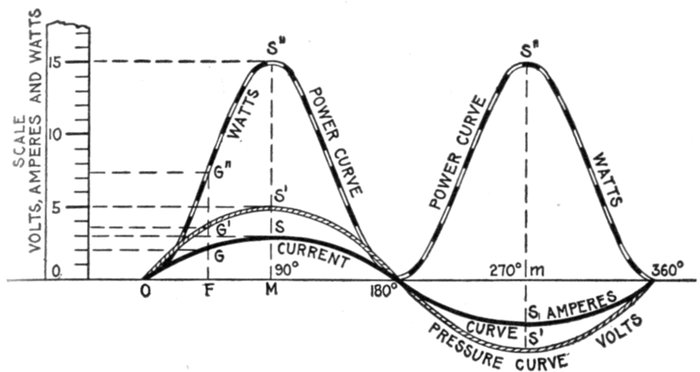

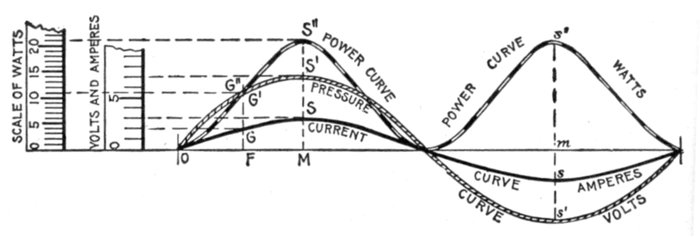

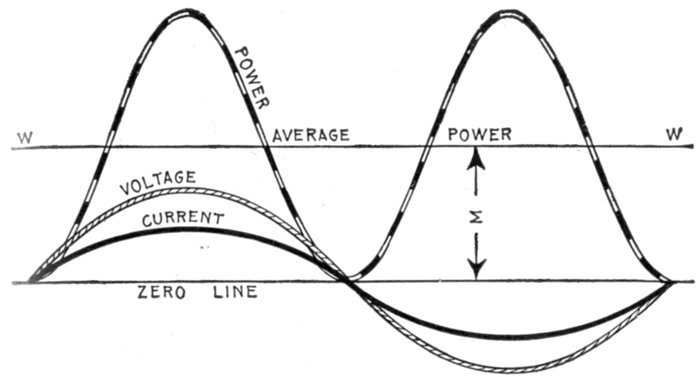

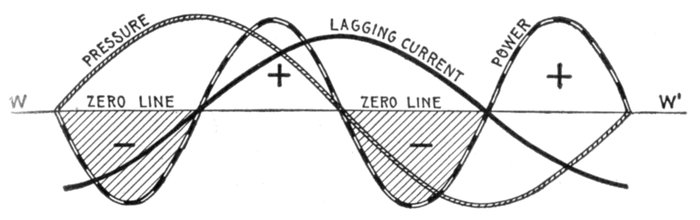

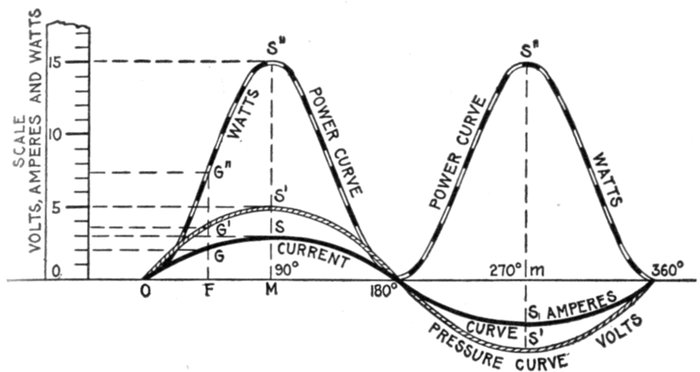

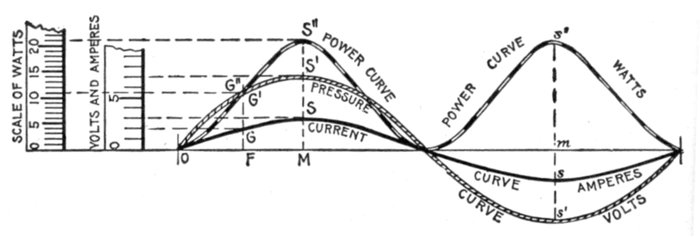

to obtain the power curve—nature of the

power curve—synchronism of current and pressure;

power factor unity—case of

synchronism of current and pressure with power factor less

than unity—steam engine analogy

of power factor—"wattless current;" power

factor zero—examples of phase difference

nearly 90 degrees—mechanical analogy of wattless

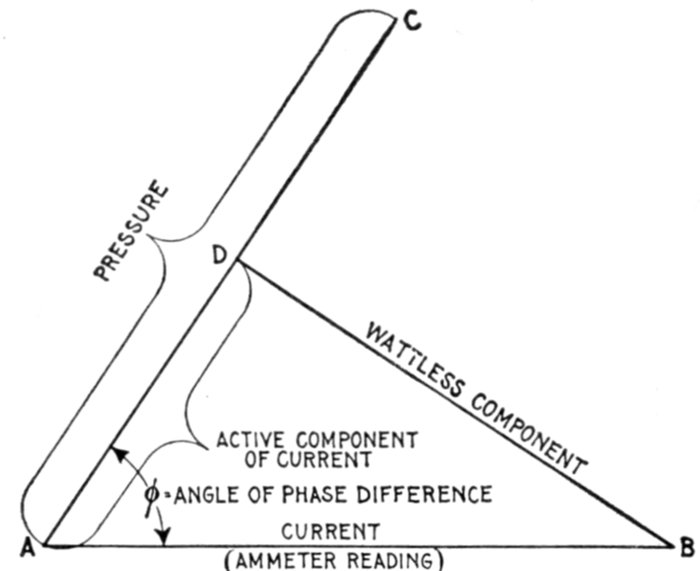

current—why the power factor is equal to cos

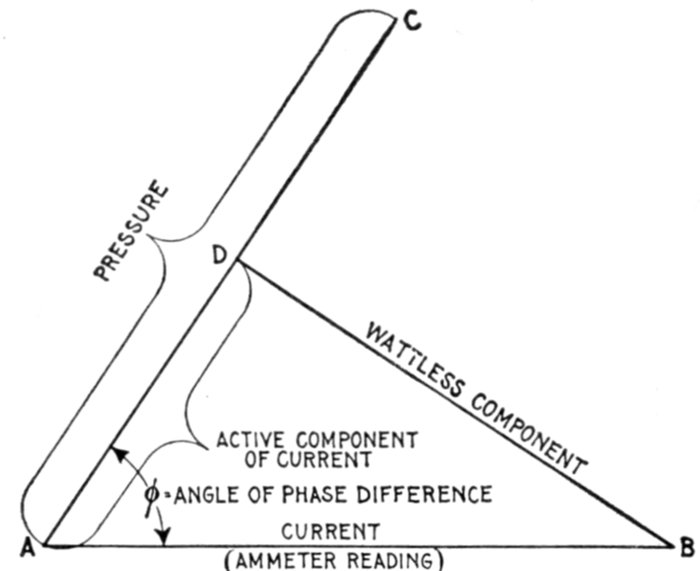

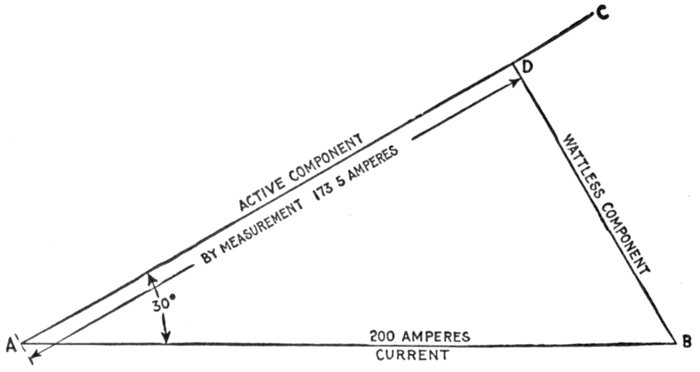

φ—graphical method of obtaining the

active component—examples and diagrams—effect

of capacity—diagrams illustrating why the power

factor is unity when there is no resultant

reactance in the circuit—usual value of power

factor—power factor test—how

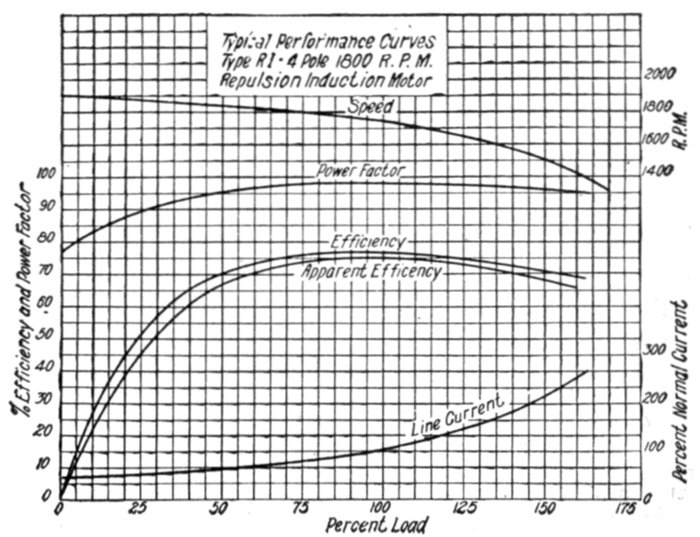

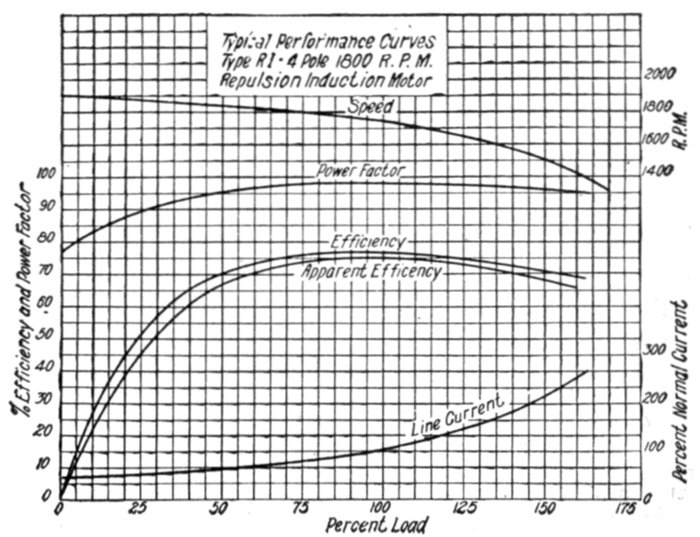

alternators are rated; kva.—curves illustrating

power factor—how to keep the power factor

high—why power factor is important in station

operation—wattmeter method of three phase power

measurement. |

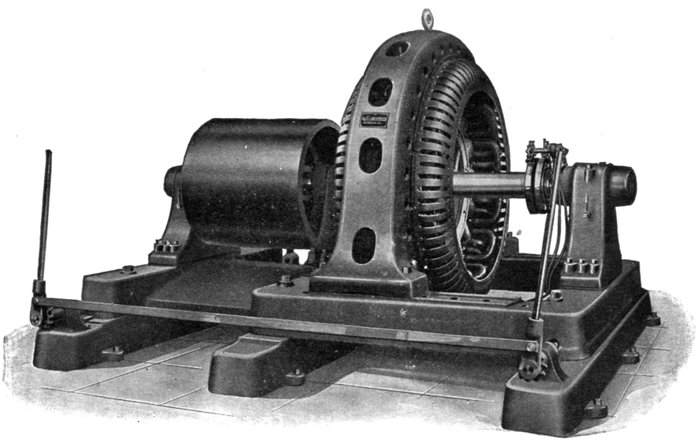

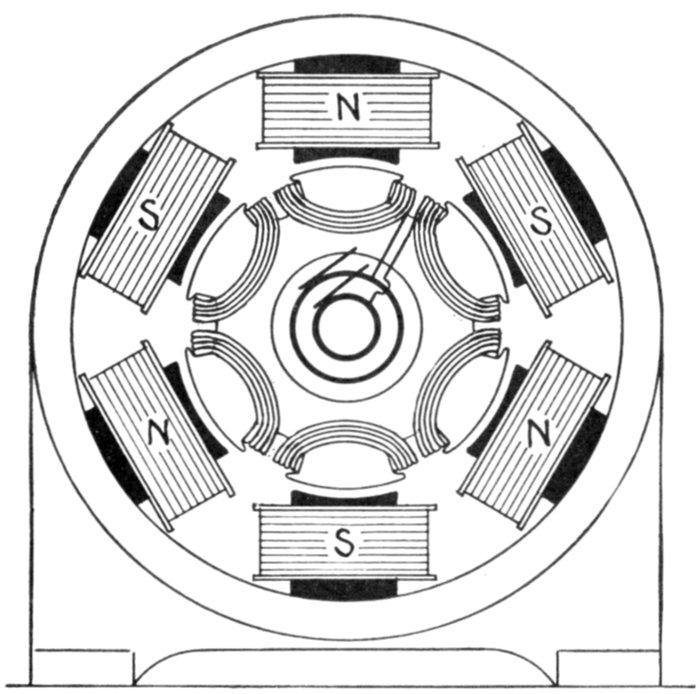

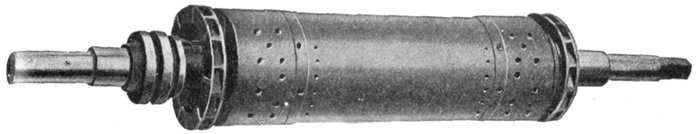

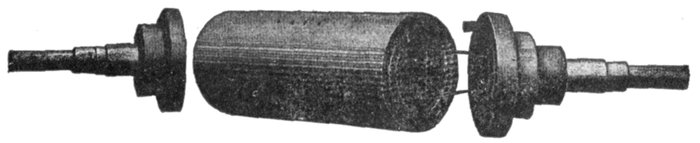

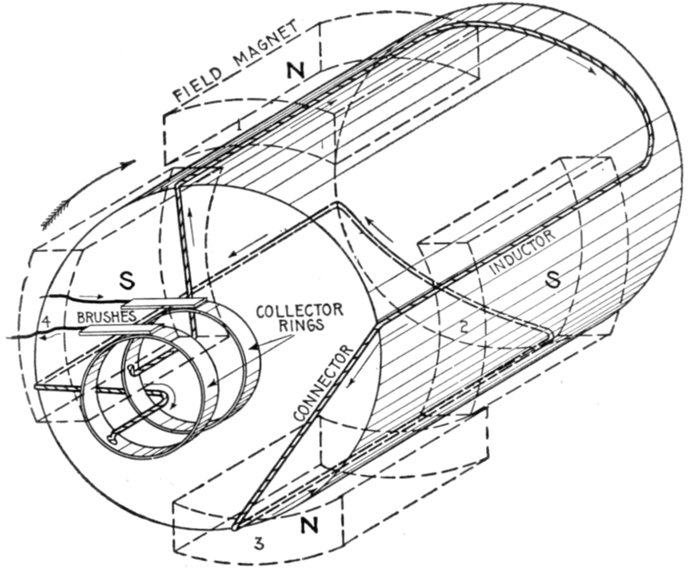

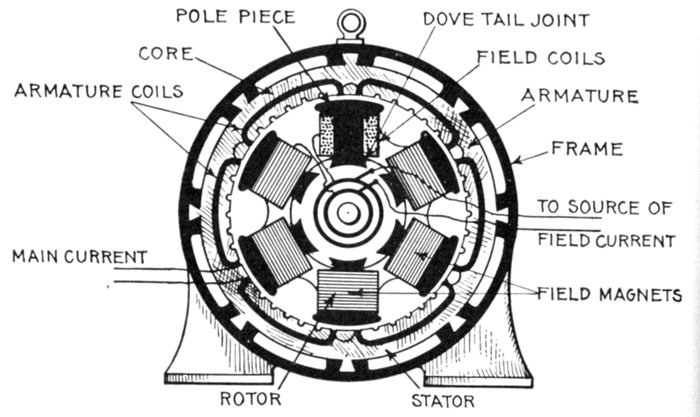

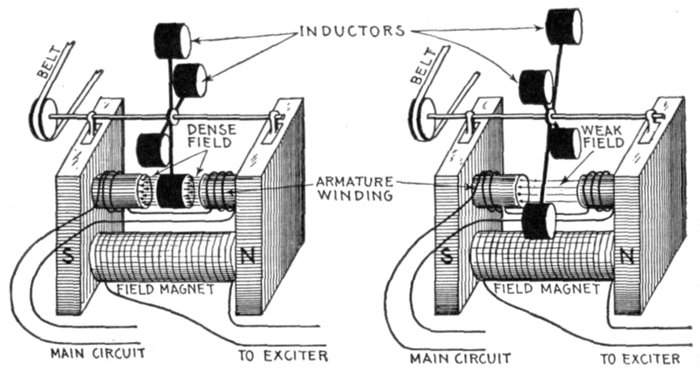

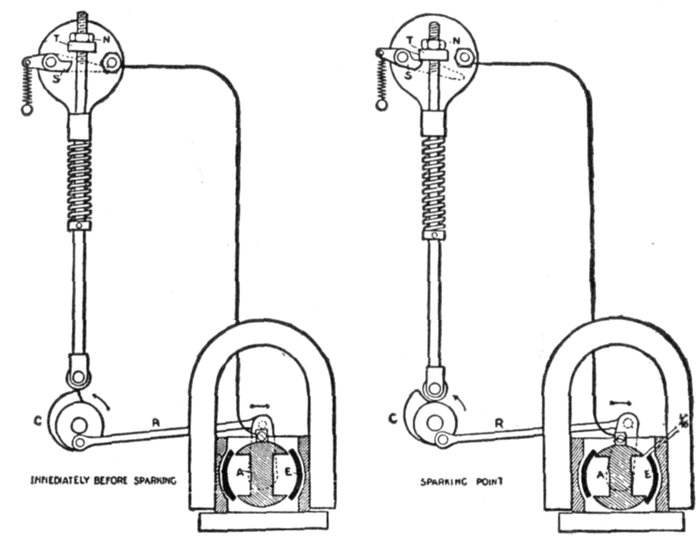

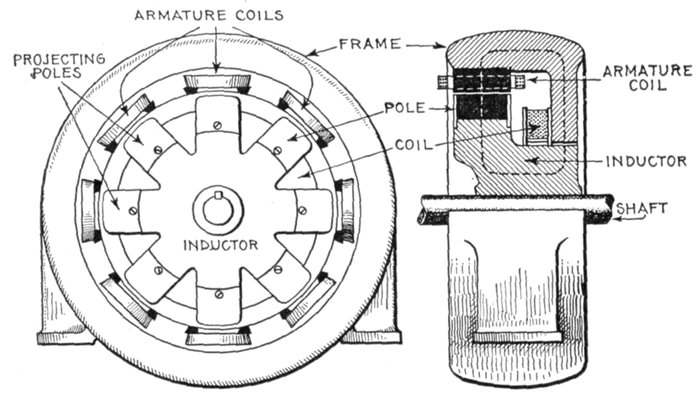

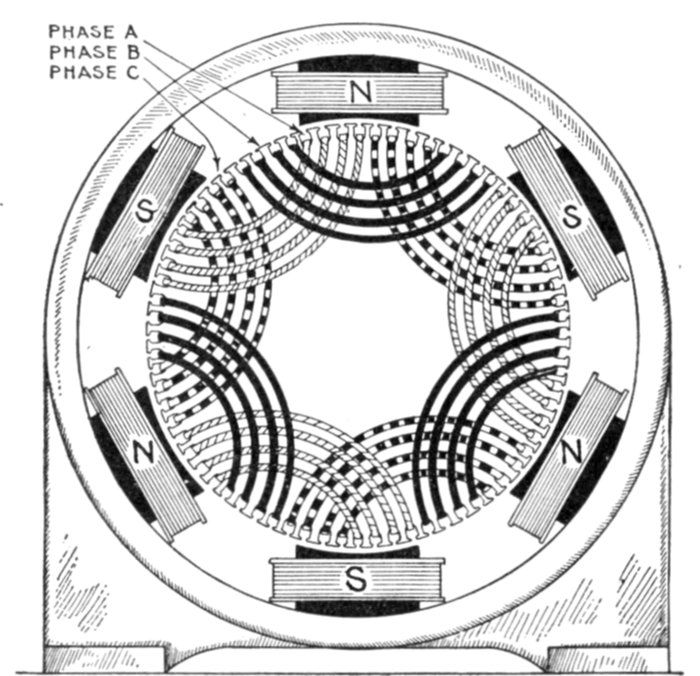

| ALTERNATORS |

1,125 to 1,186 |

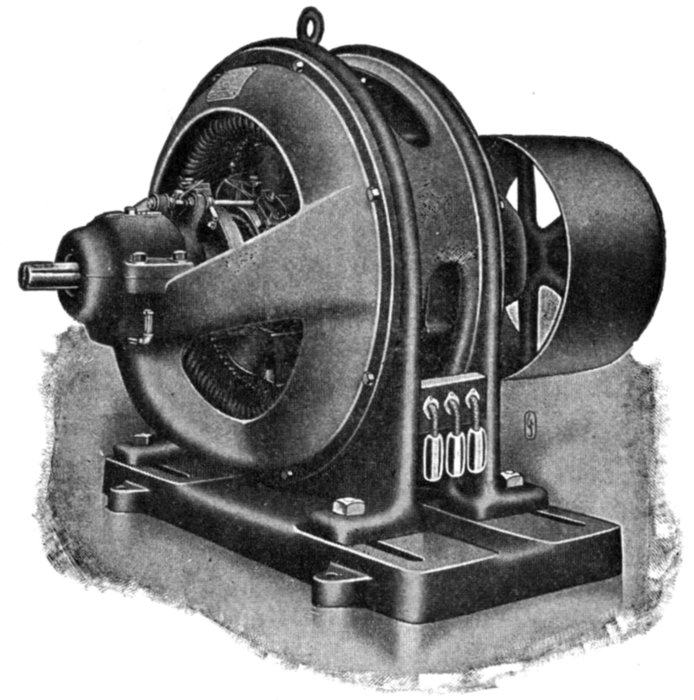

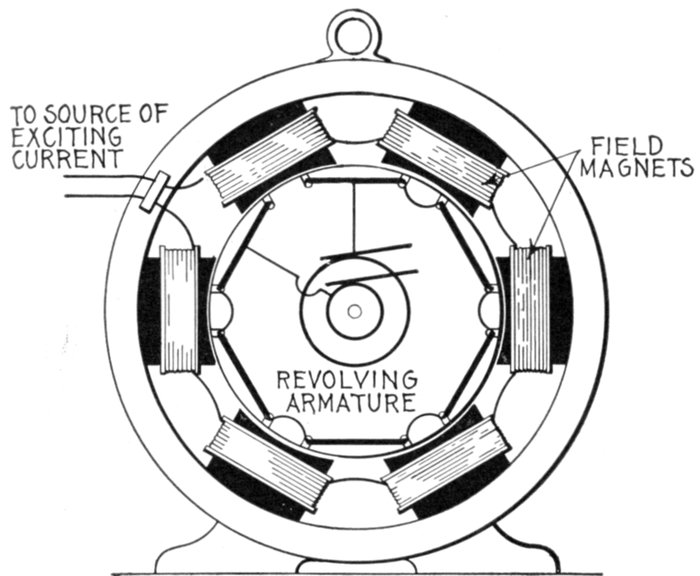

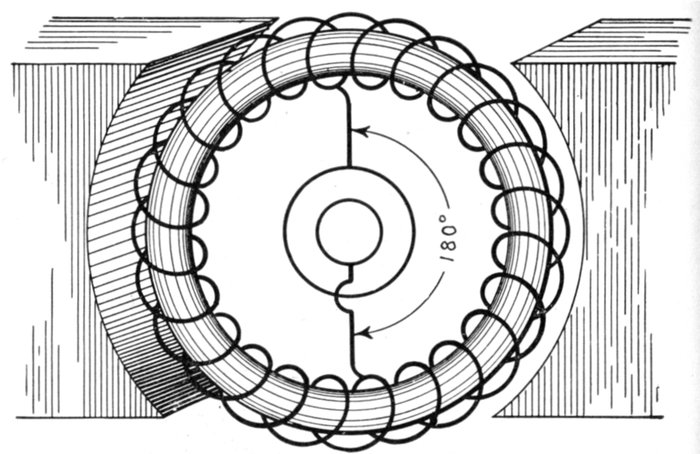

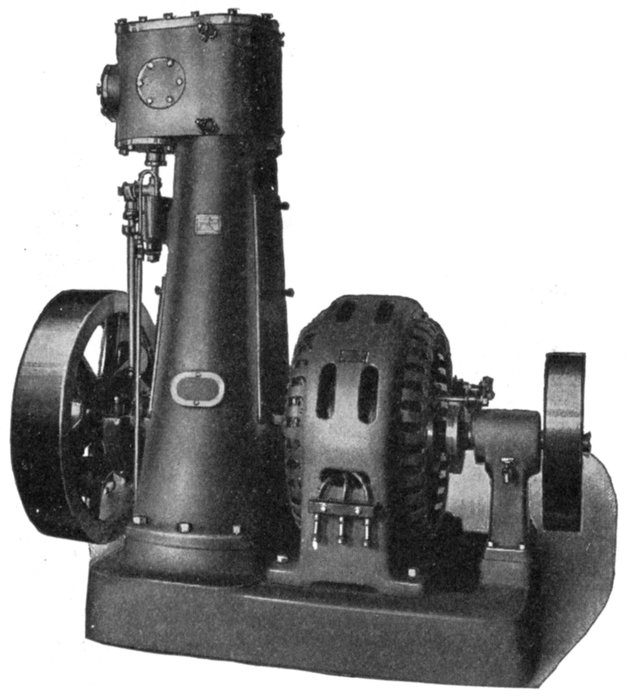

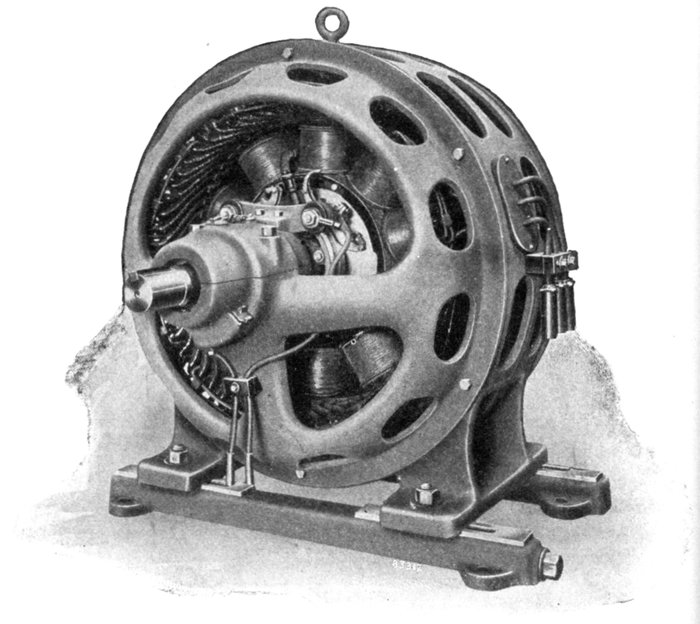

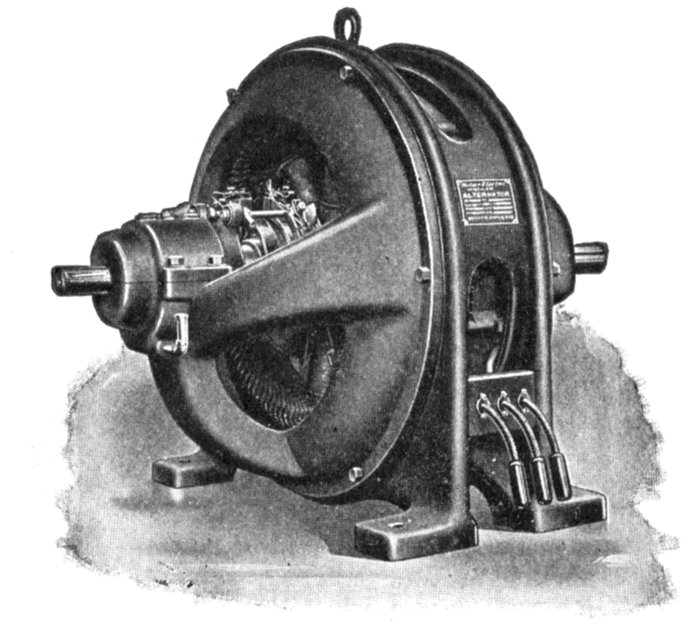

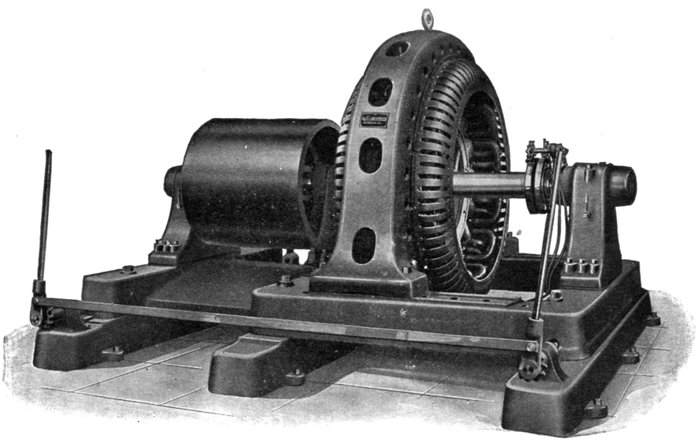

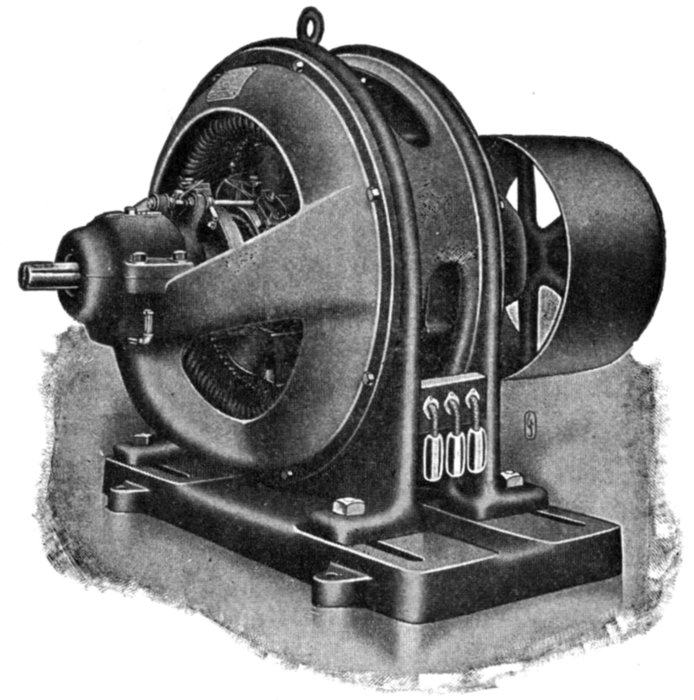

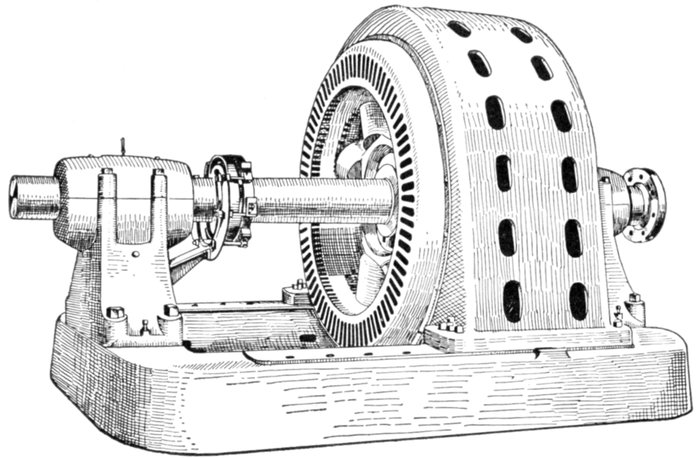

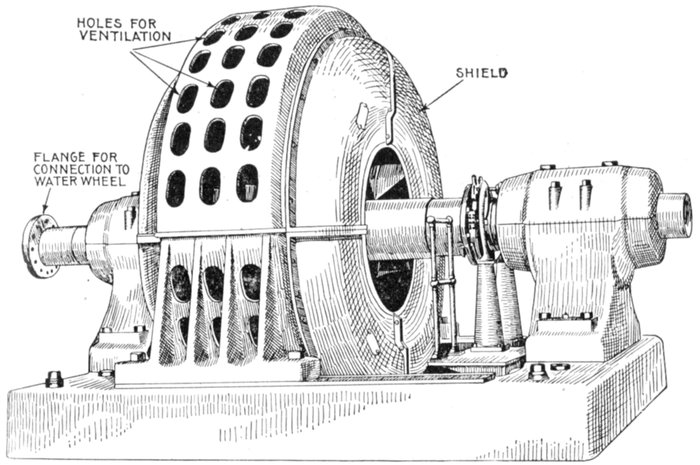

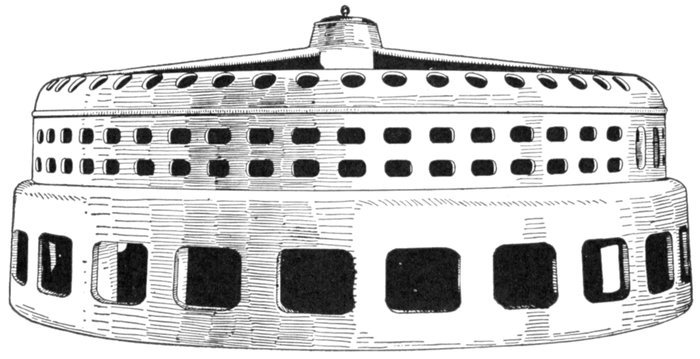

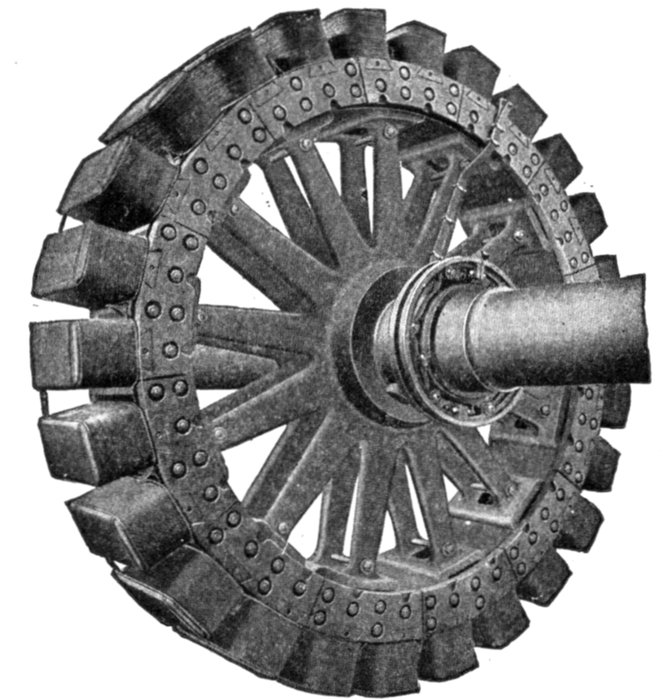

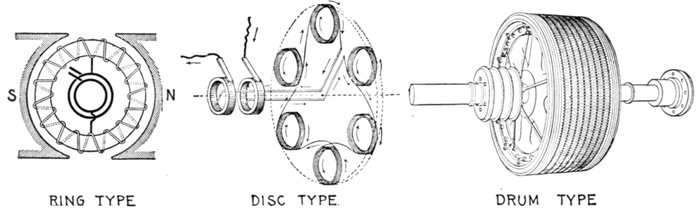

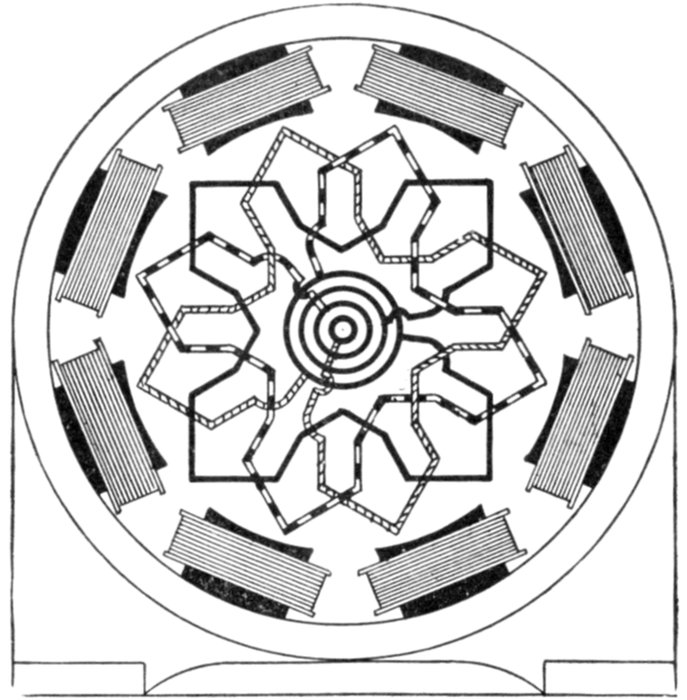

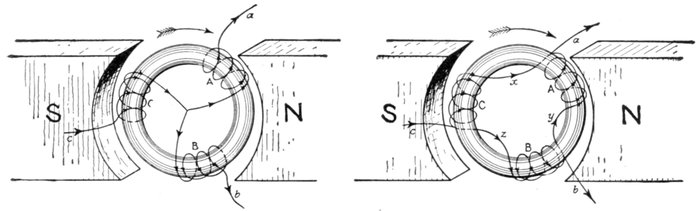

| Uses of alternators—classes

of alternator—single phase

alternators; essential features; width

of armature coils—[Pg v]elementary

single phase alternator—polyphase

alternators—uses for two and three phase

current—elementary three phase alternator—starting

difficulty with single phase motors—six and twelve

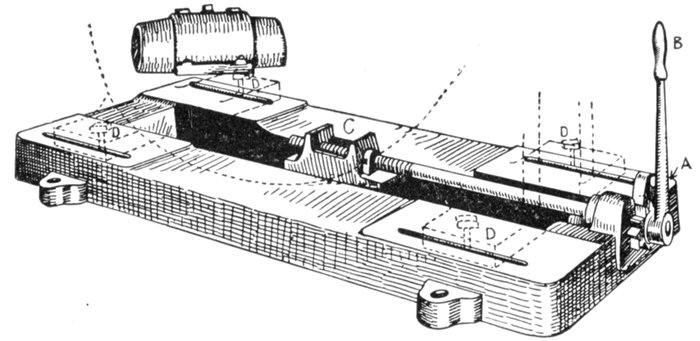

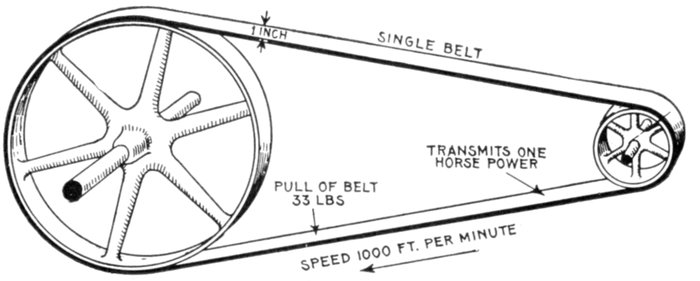

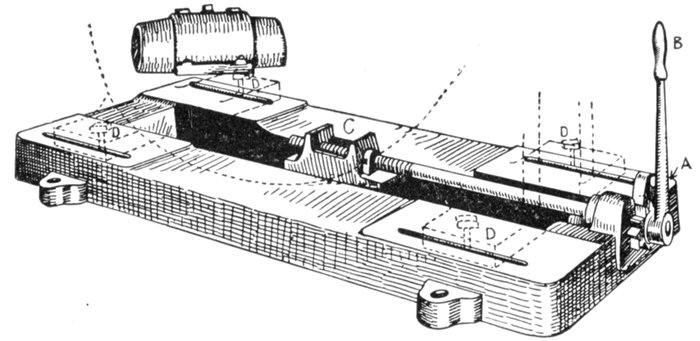

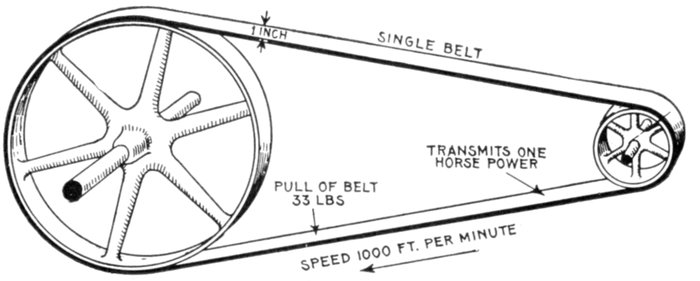

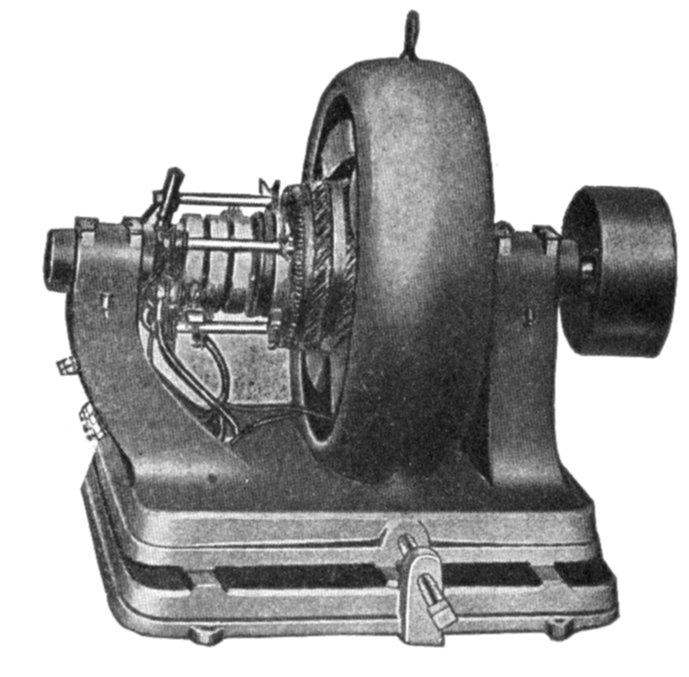

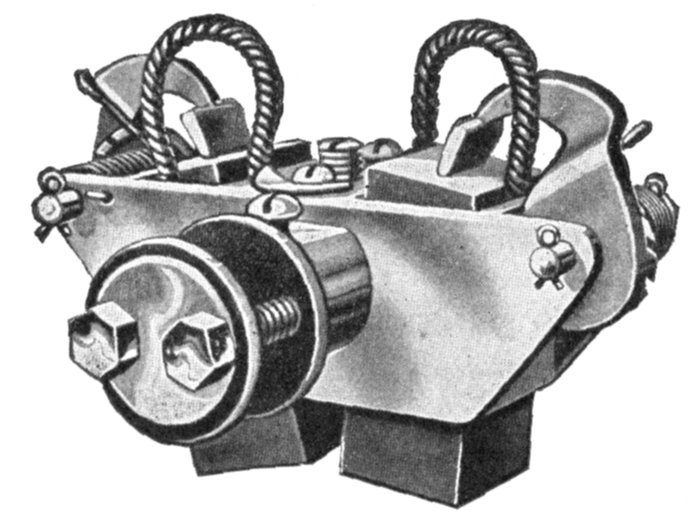

phase windings—belt or chain driven

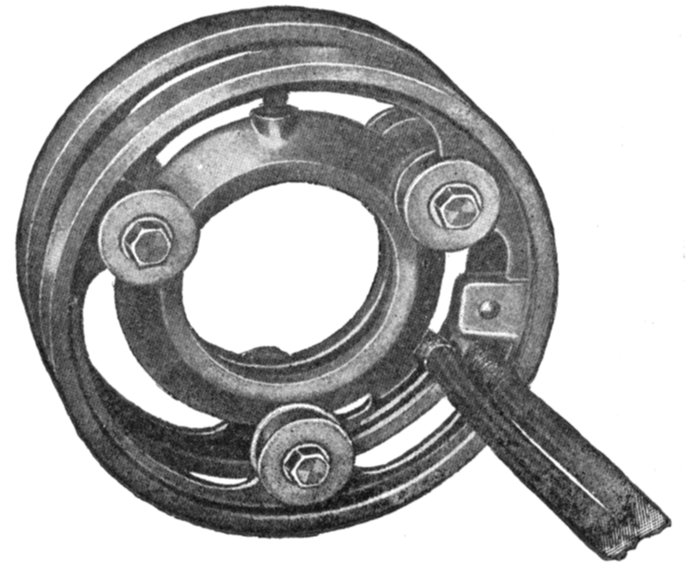

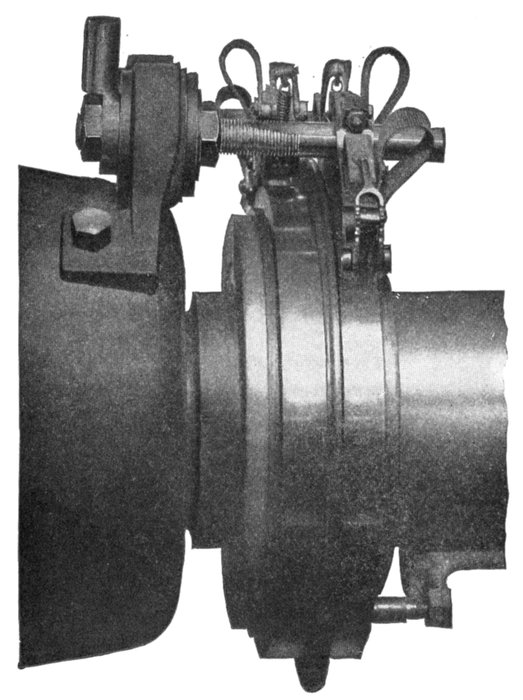

alternators—sub-base and ratchet device for

tightening the belt—horse power transmitted by

belts—best speeds for belts—advantages

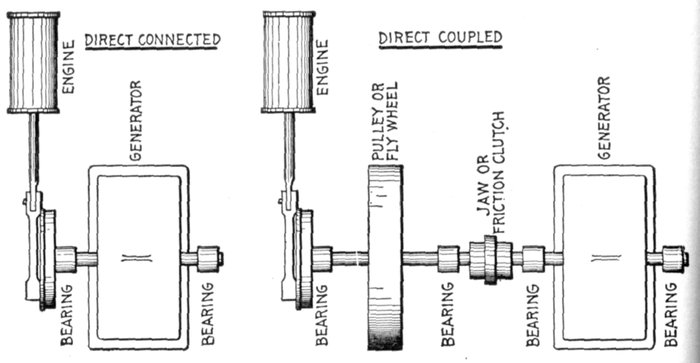

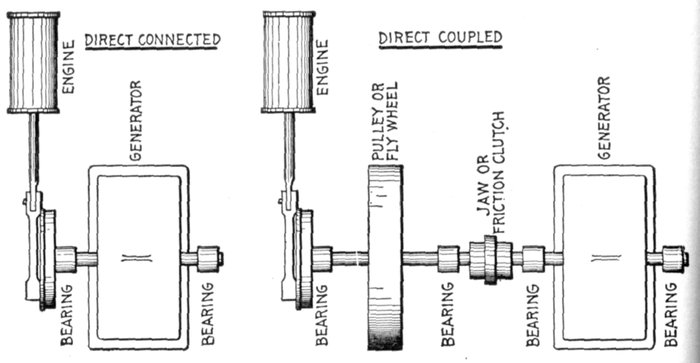

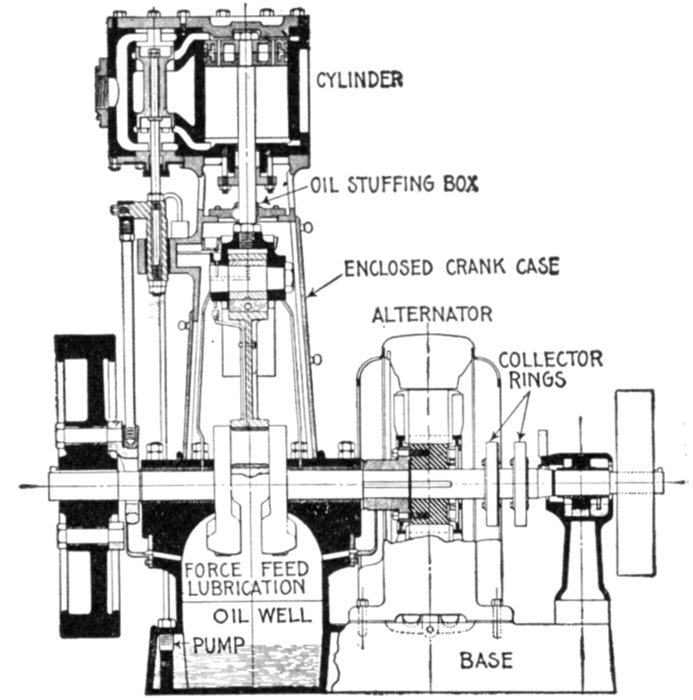

of chain drive; objections—direct connected

alternator—"direct connected" and

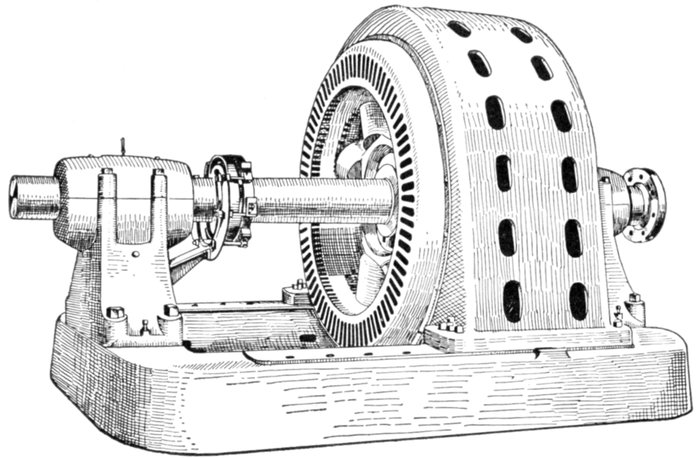

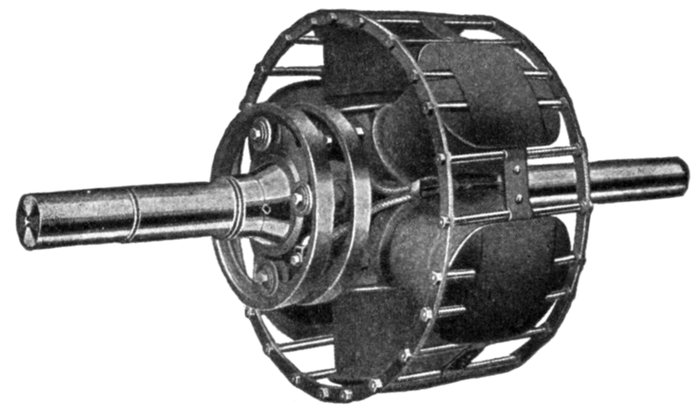

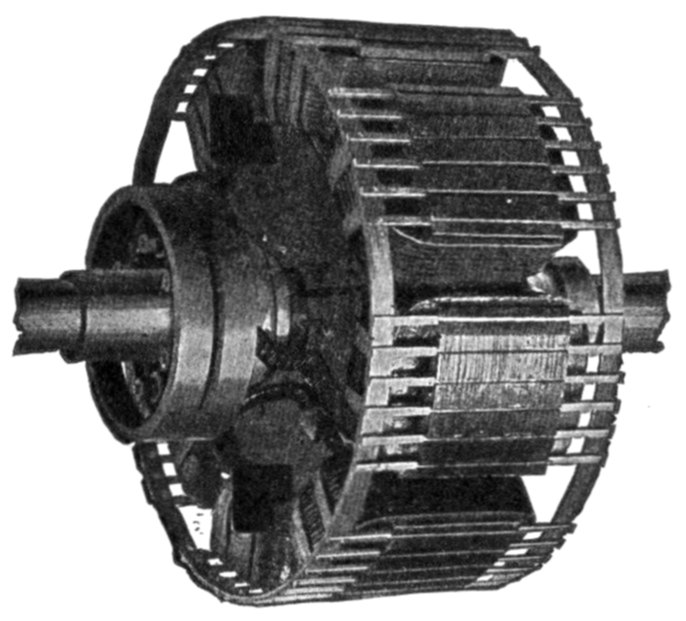

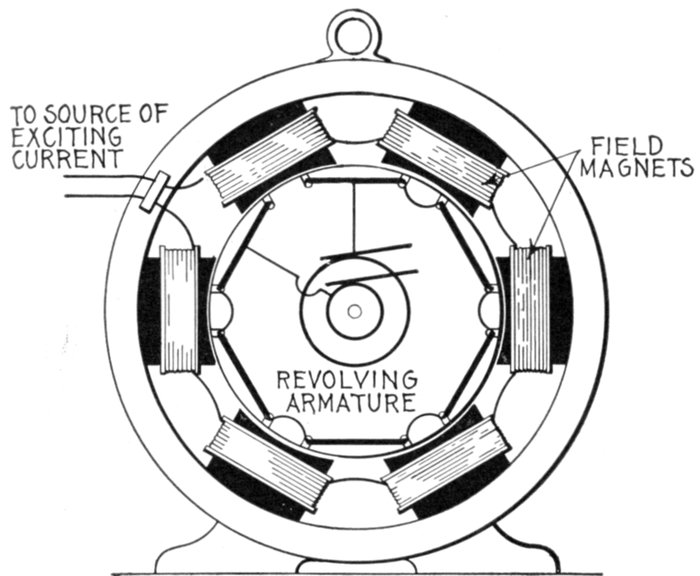

"direct coupled" units—revolving armature

alternators; their uses—revolving

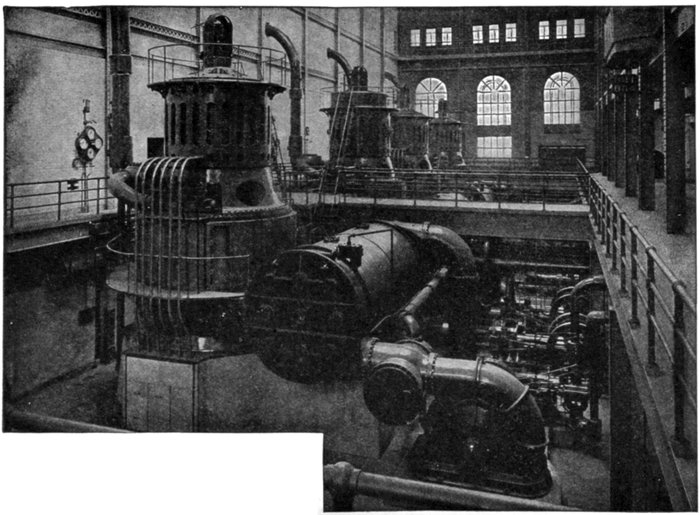

field alternators—marine view showing

that motion is purely a relative matter—essential

parts of revolving field alternator—the terms

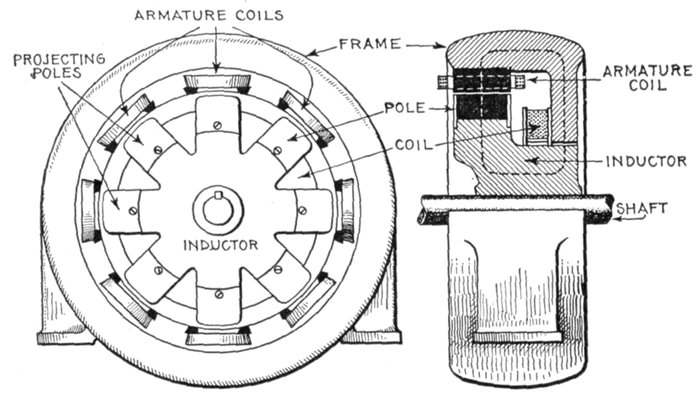

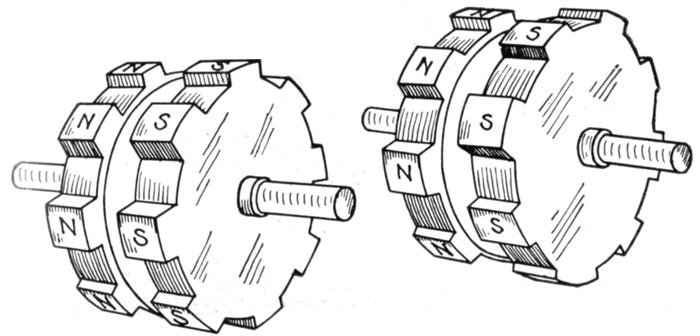

"stator" and "rotor"—inductor alternators:

classes, use, defects—hunting or surging in

alternators—amortisseur

windings—monocyclic

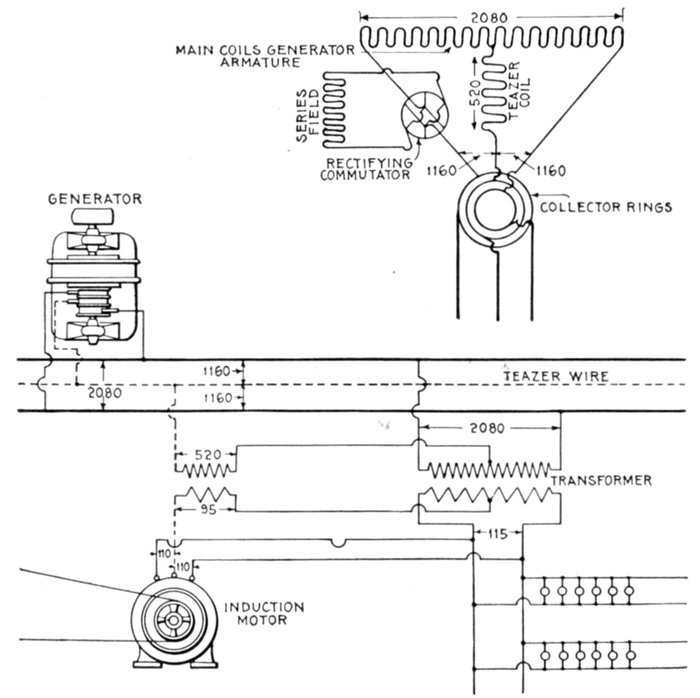

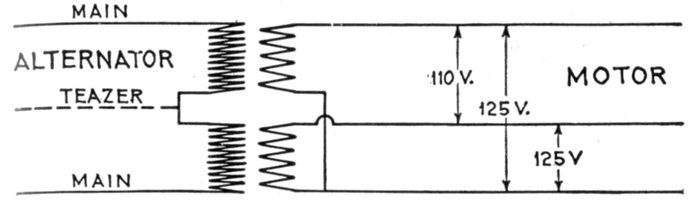

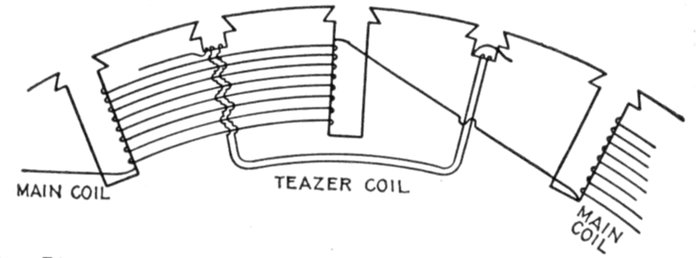

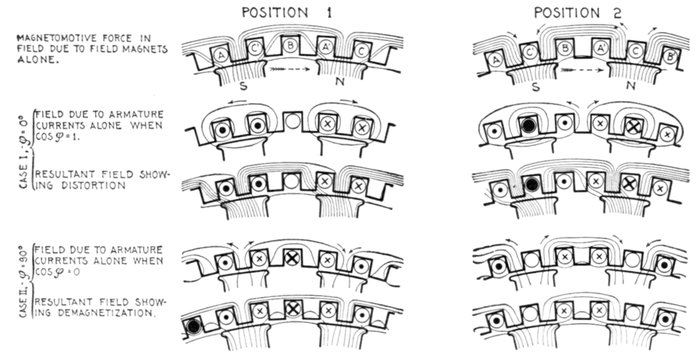

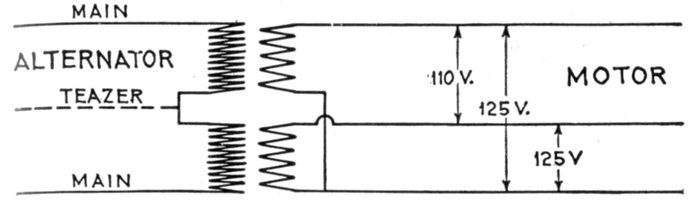

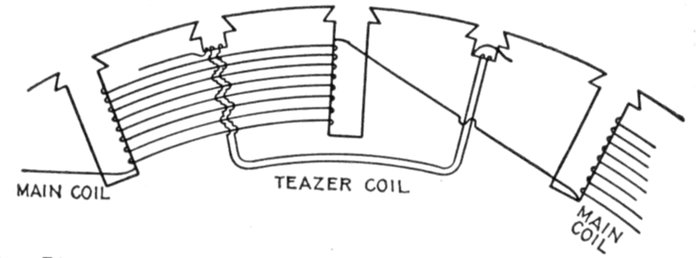

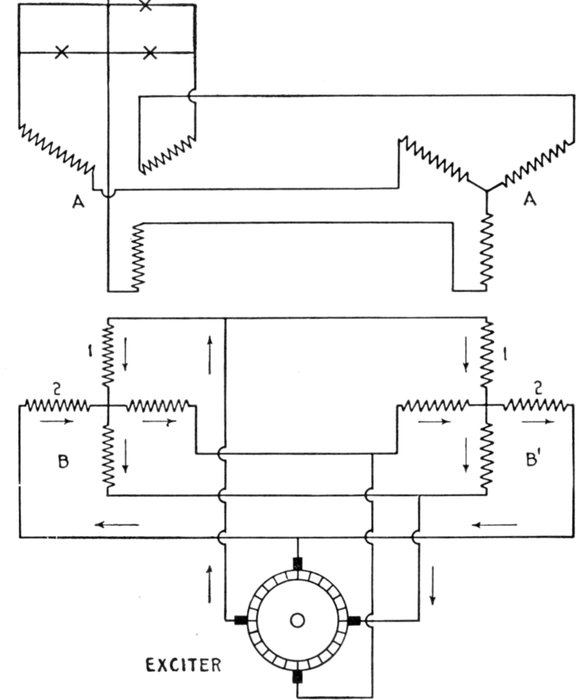

alternators—diagram of

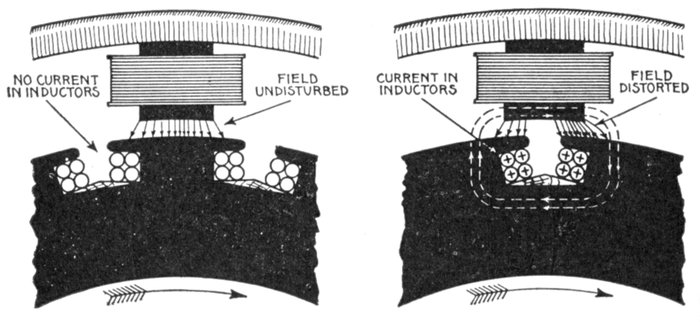

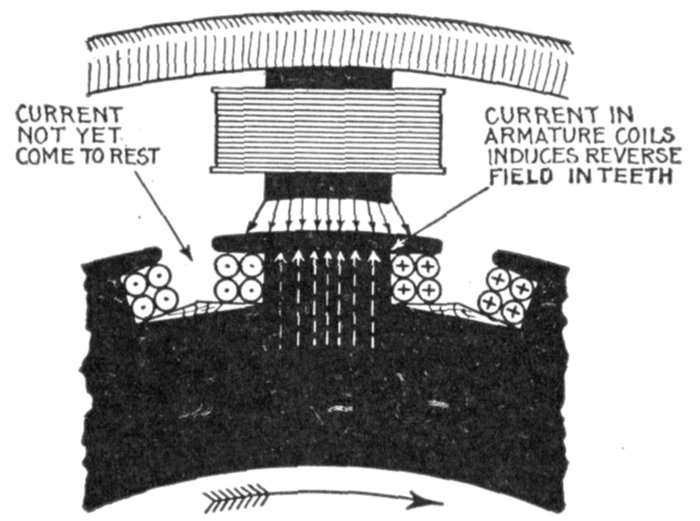

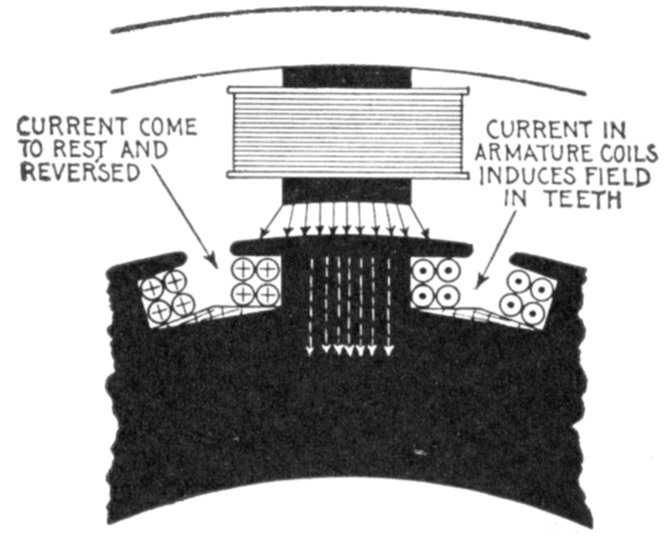

connections—teaser coil—armature

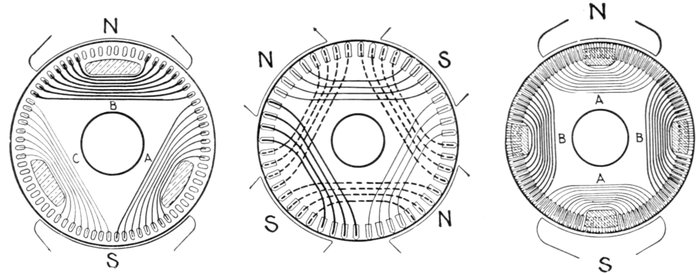

reaction—distortion of field—strengthening

and weakening effects—superpositions of

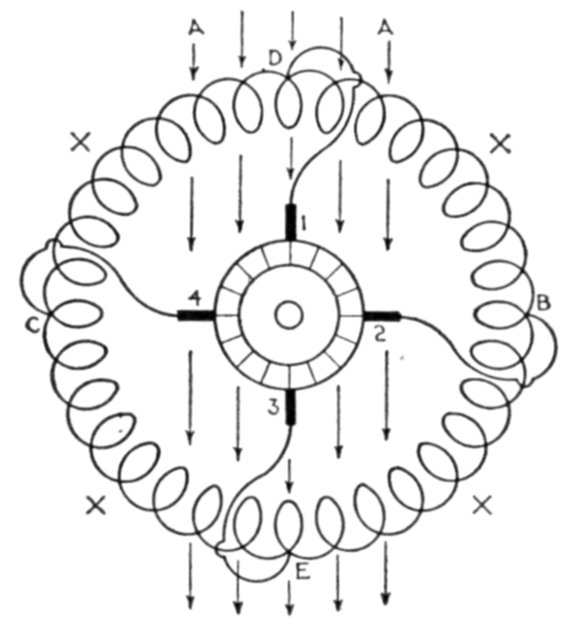

fields—three phase reactions—magnetic

leakage—field excitation of

alternators—self-excited alternator—direct

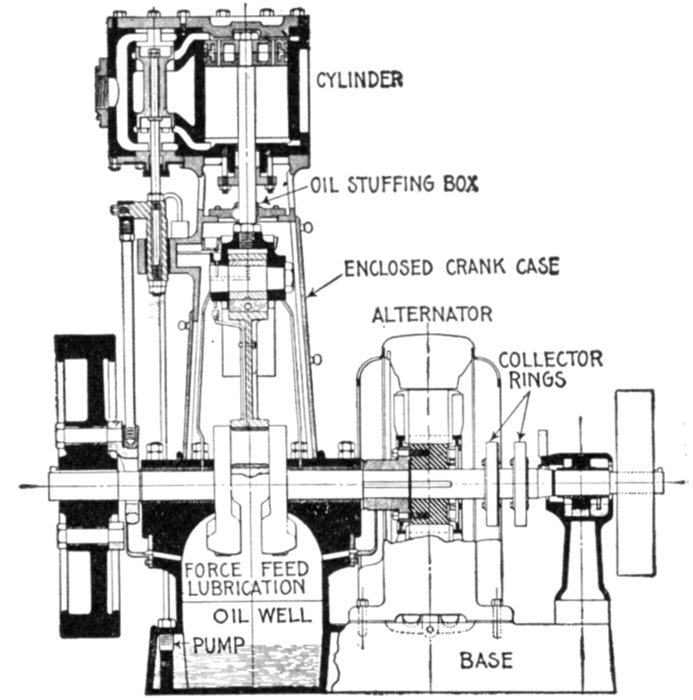

connected exciter—gear driven exciters—slow

speed alternators—fly

wheel alternators—high

speed alternators—water

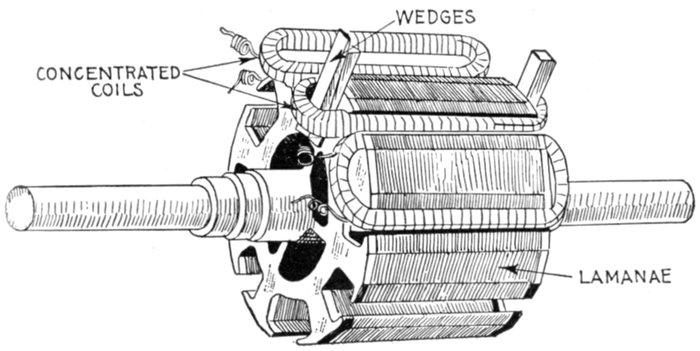

wheel alternators—construction

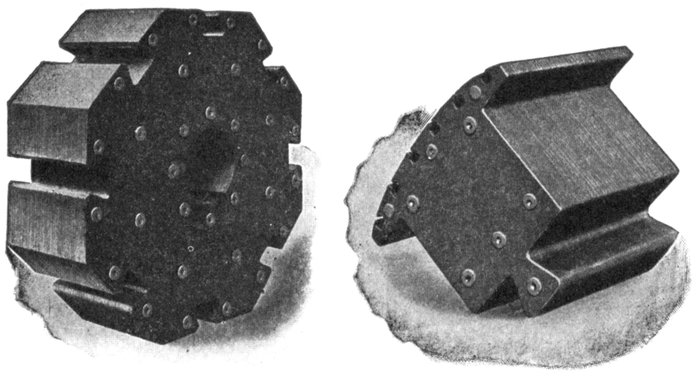

of rotor—turbine driven

alternators—construction—step

bearing—alternators of exceptional

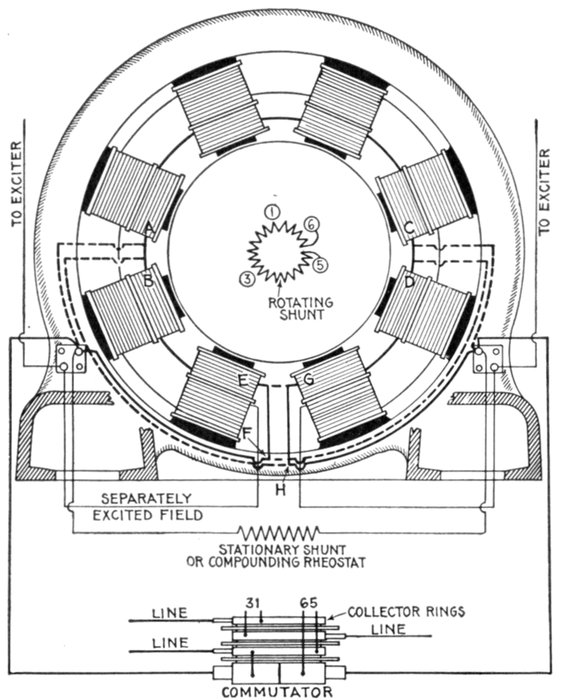

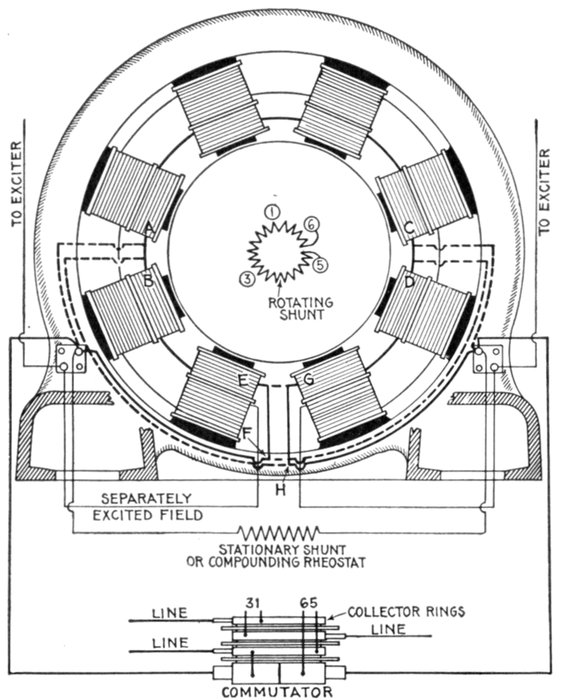

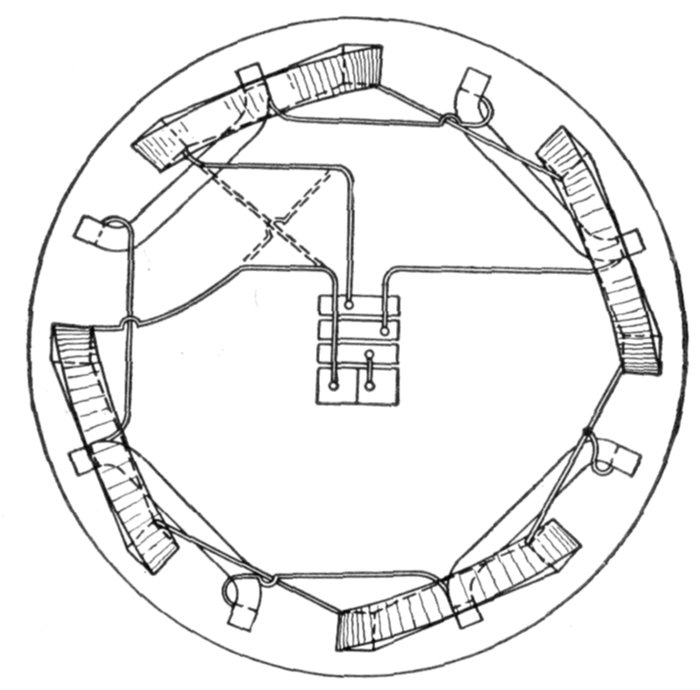

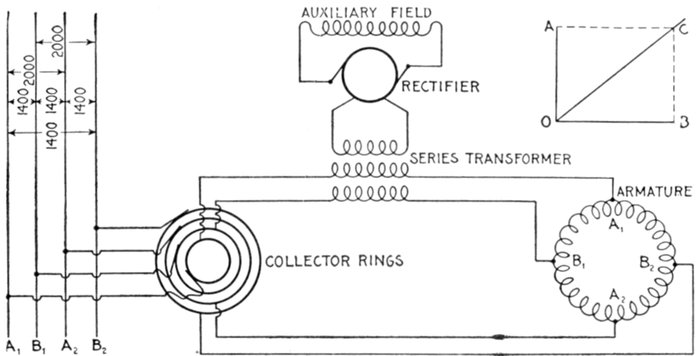

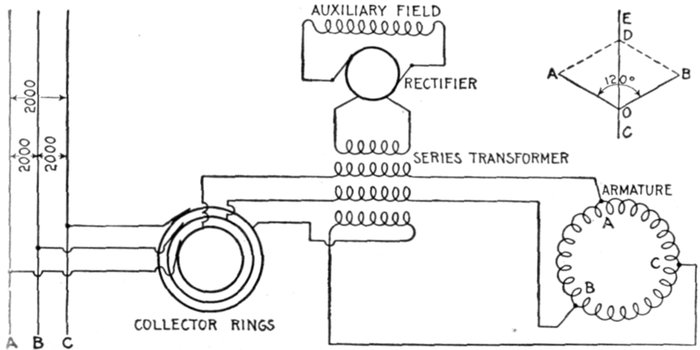

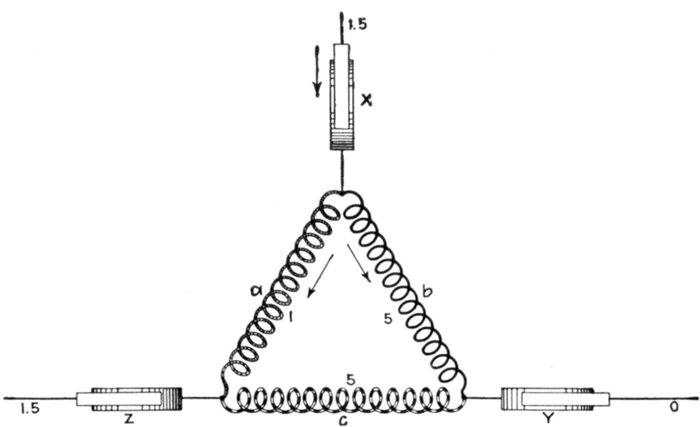

character—asynchronous alternators—image

current alternators—extra high frequency

alternators—self-exciting image current alternators. |

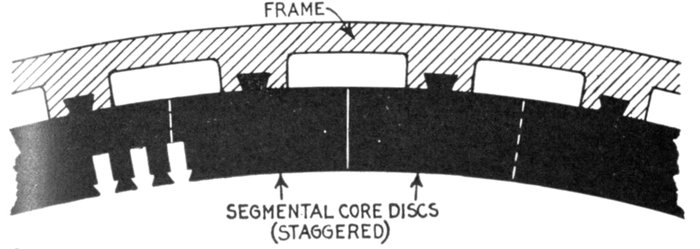

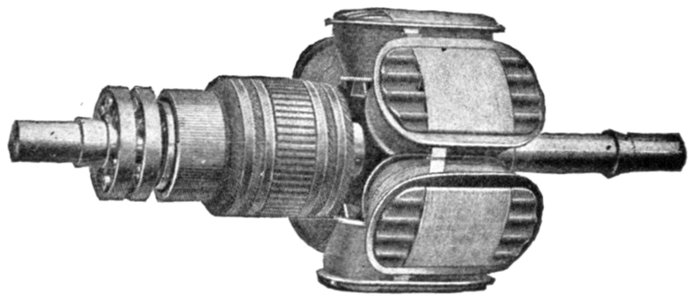

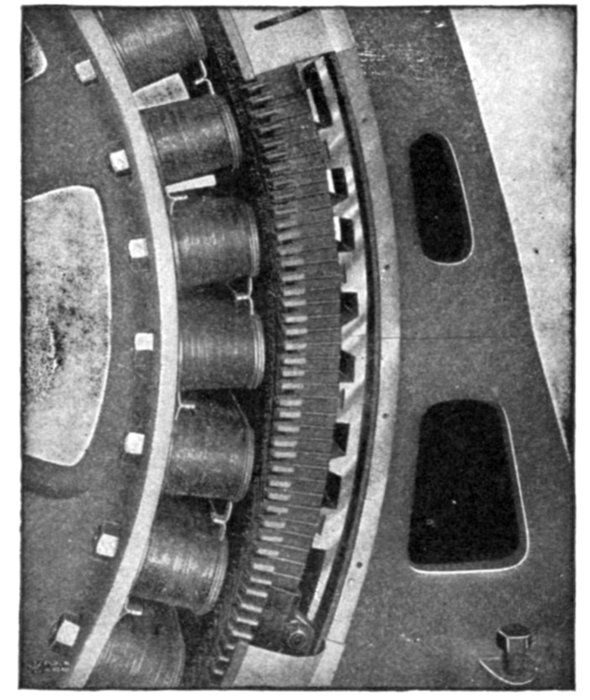

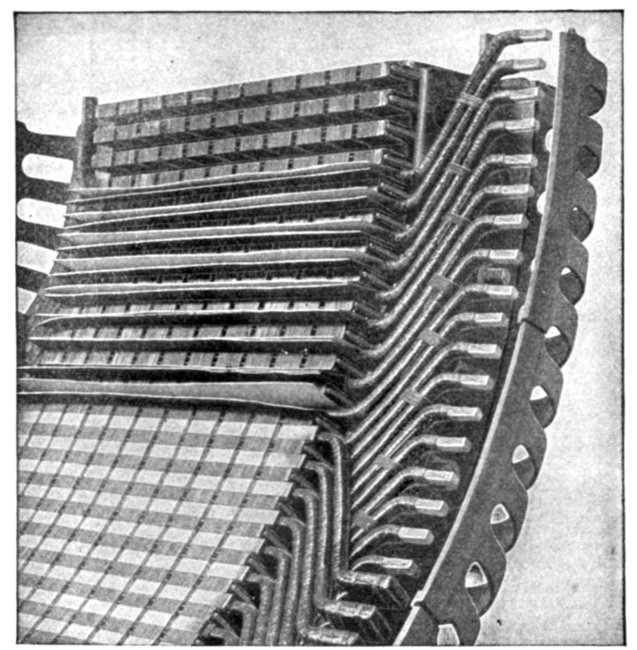

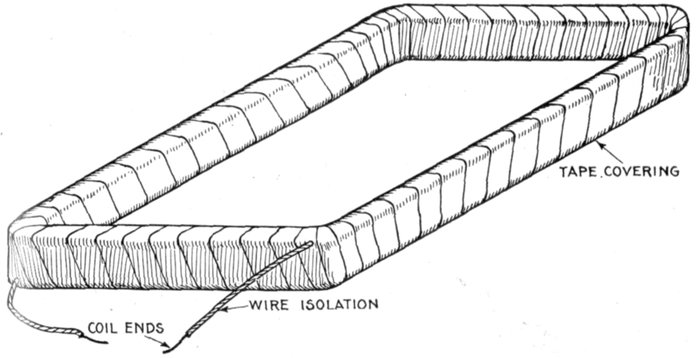

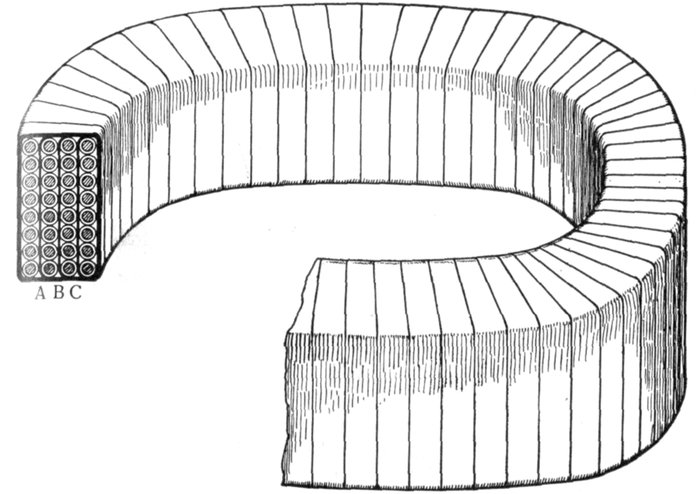

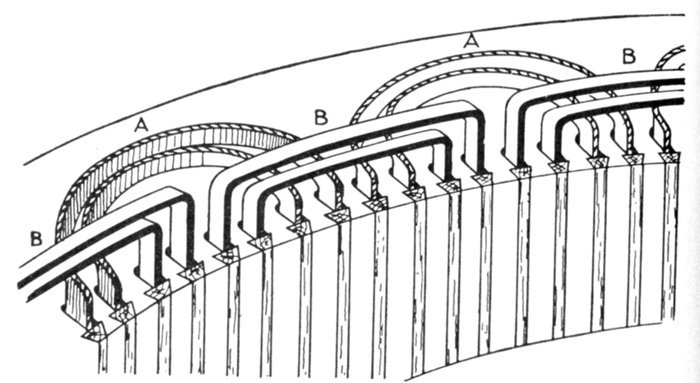

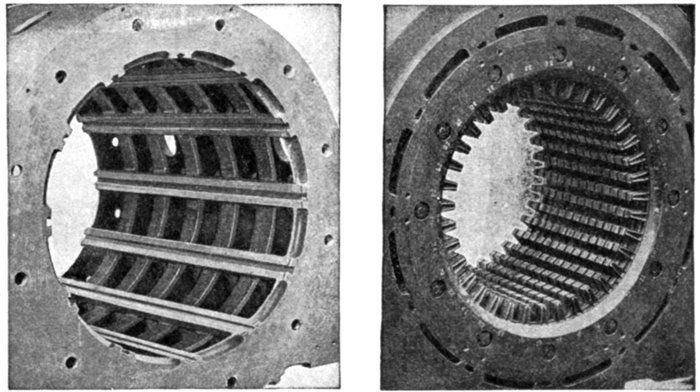

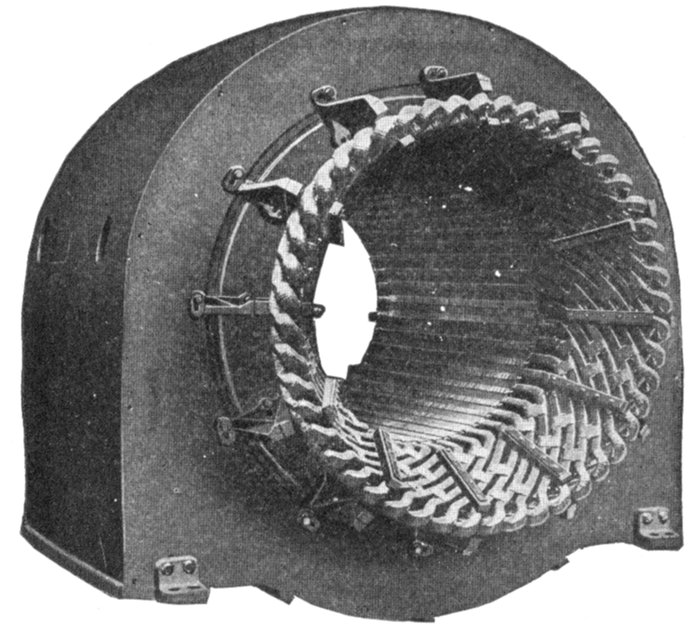

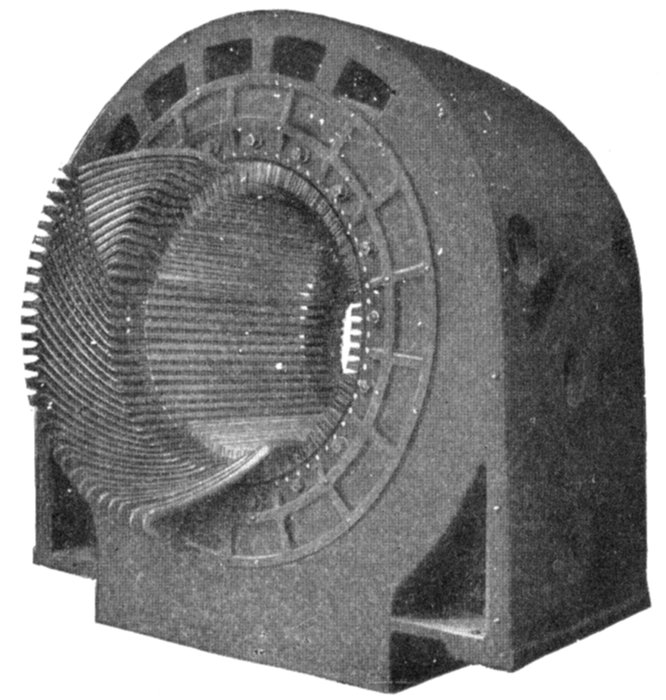

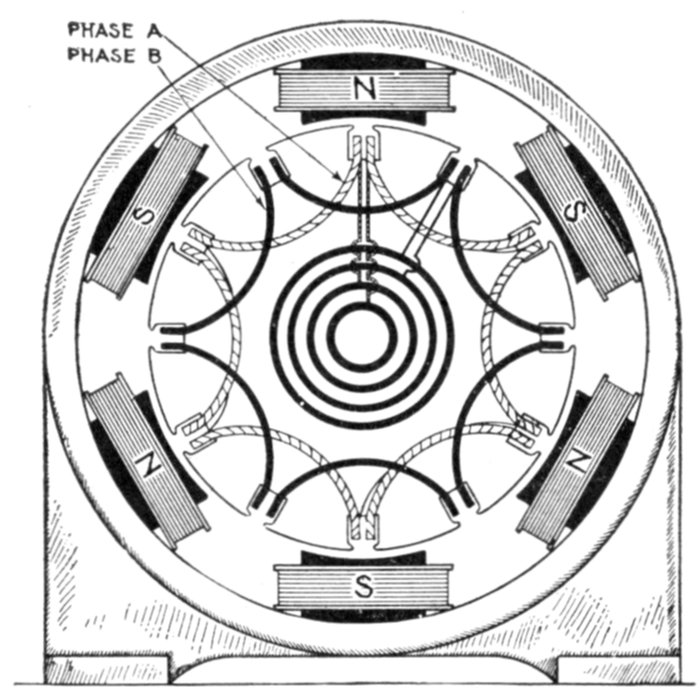

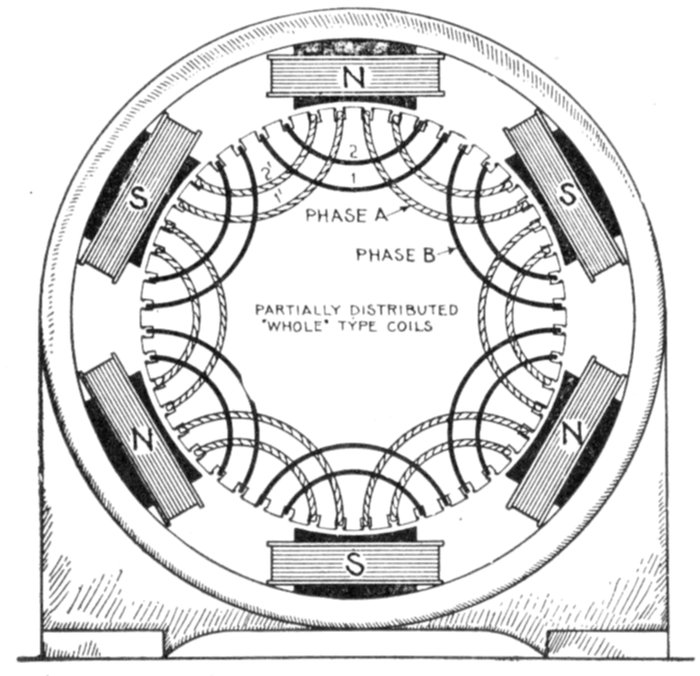

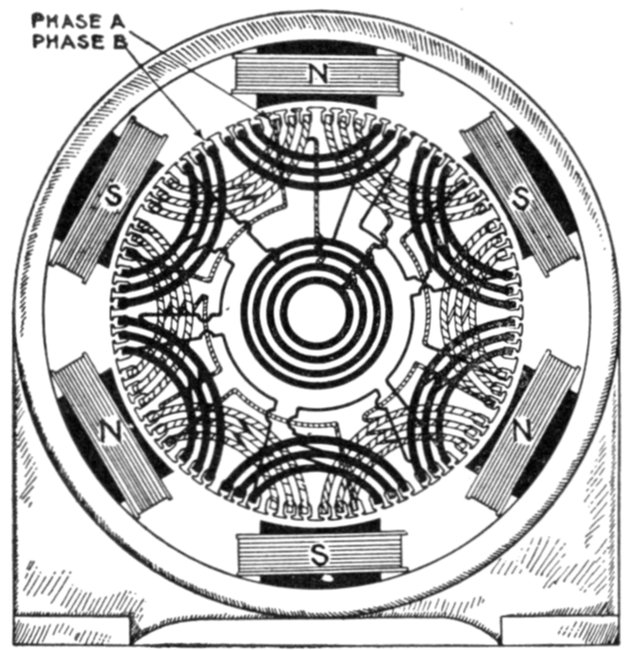

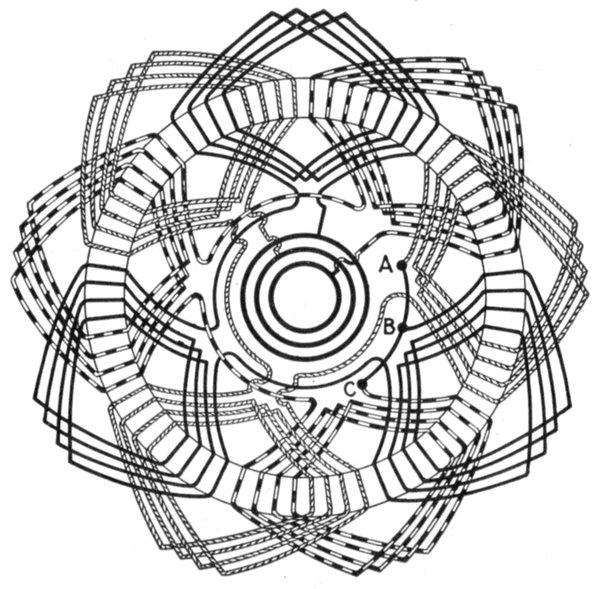

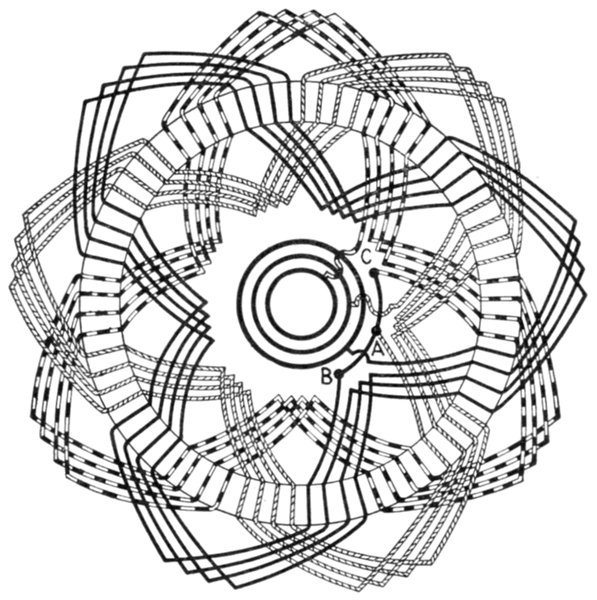

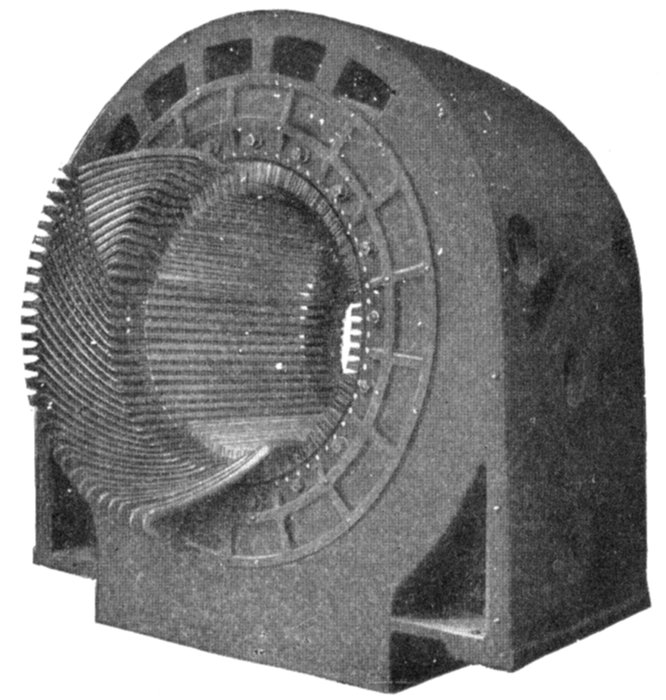

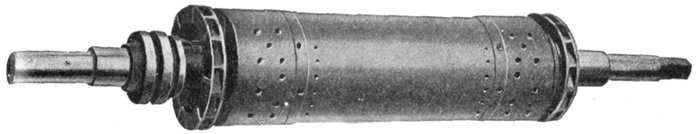

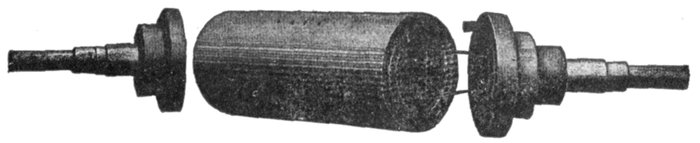

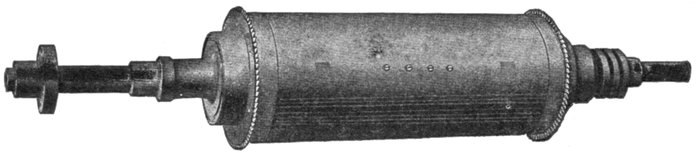

| CONSTRUCTION OF ALTERNATORS |

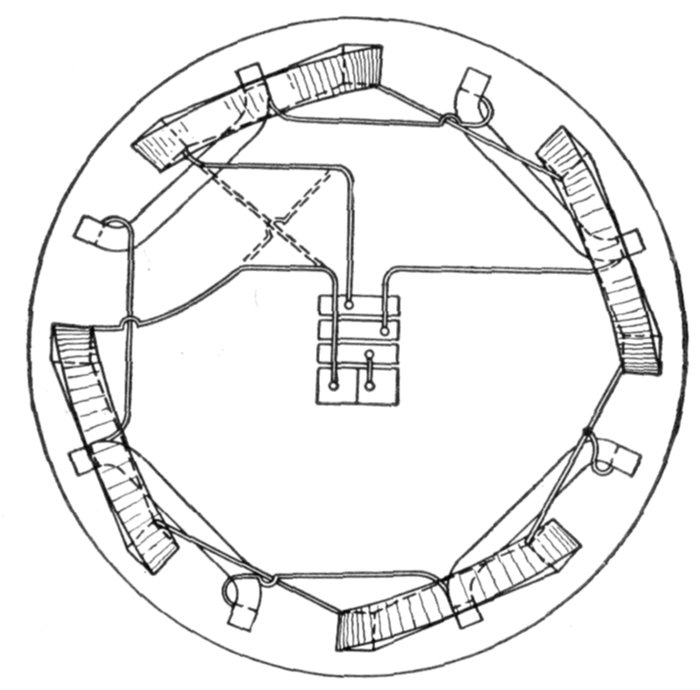

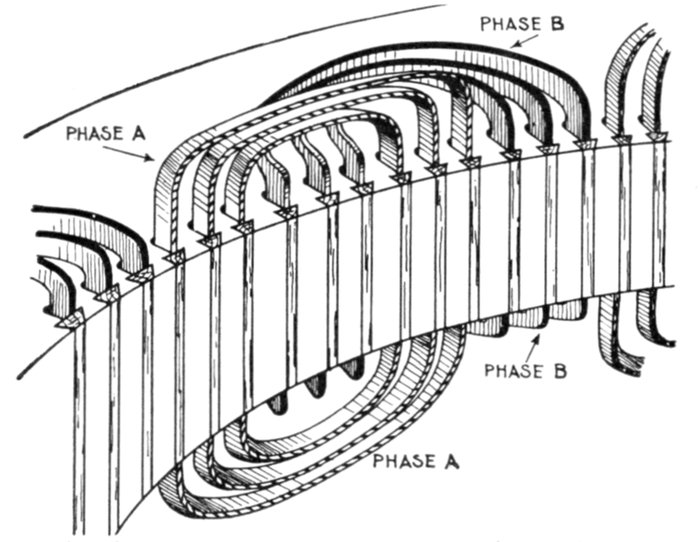

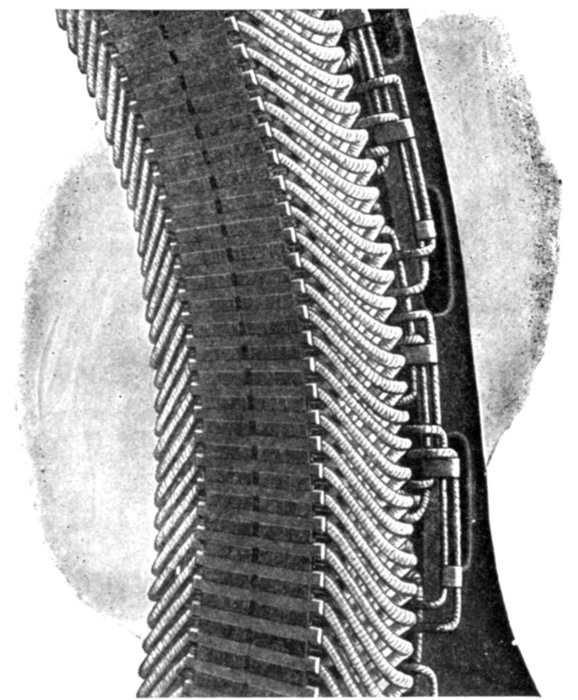

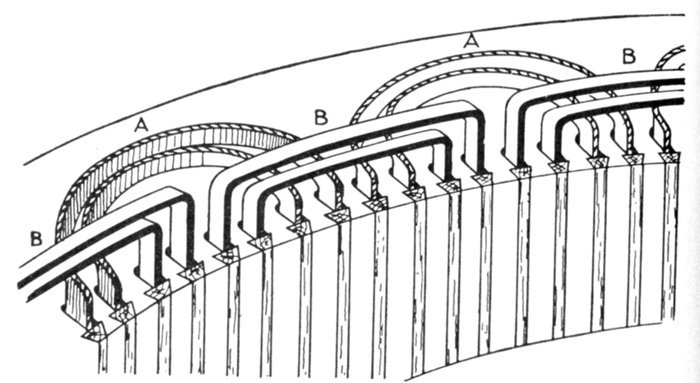

1,187 to 1,266 |

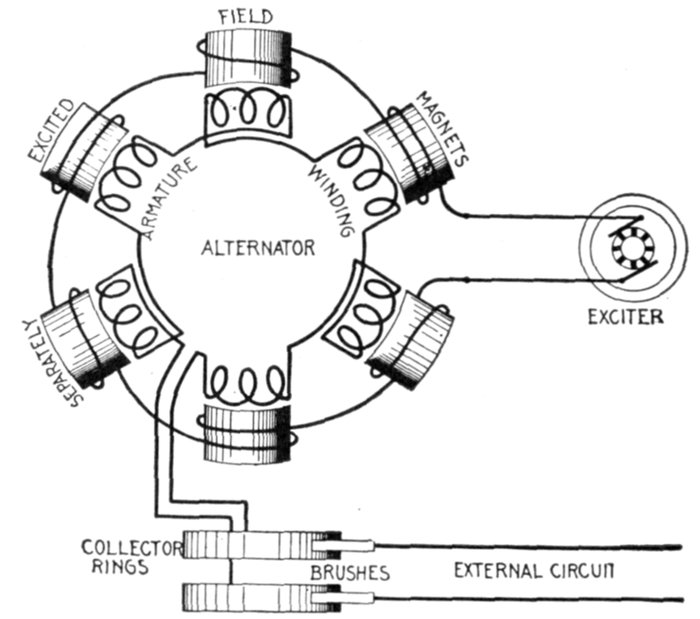

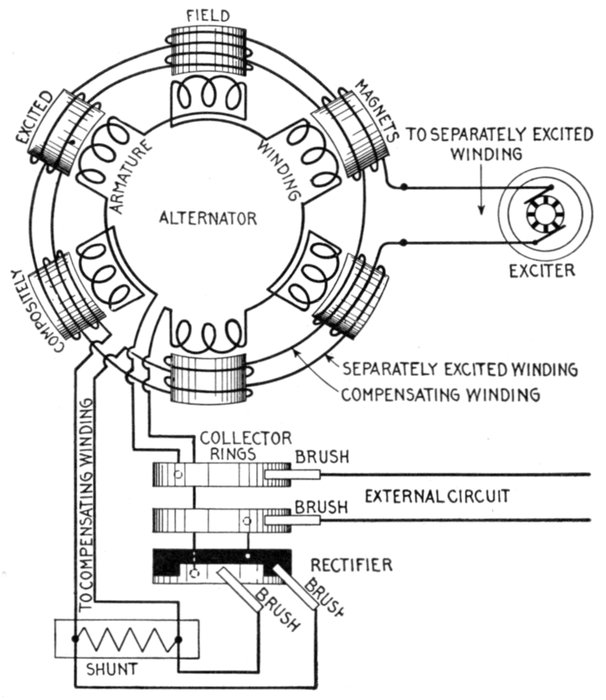

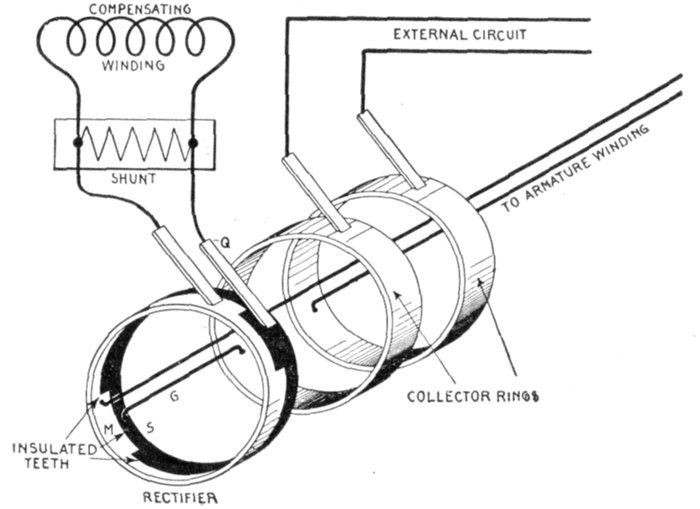

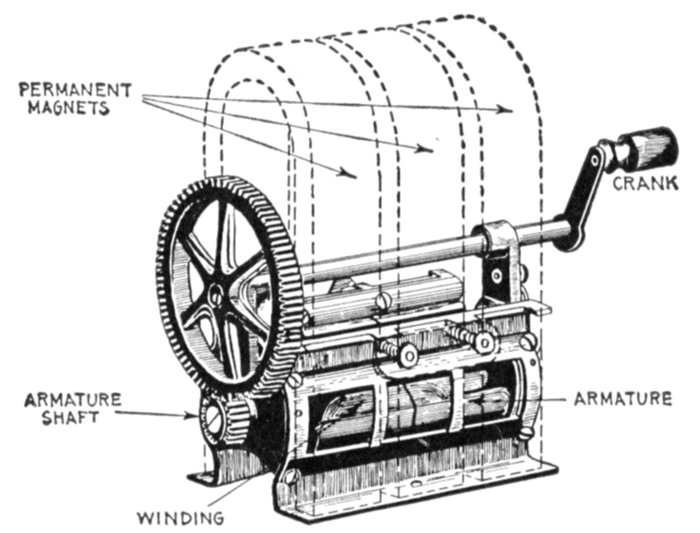

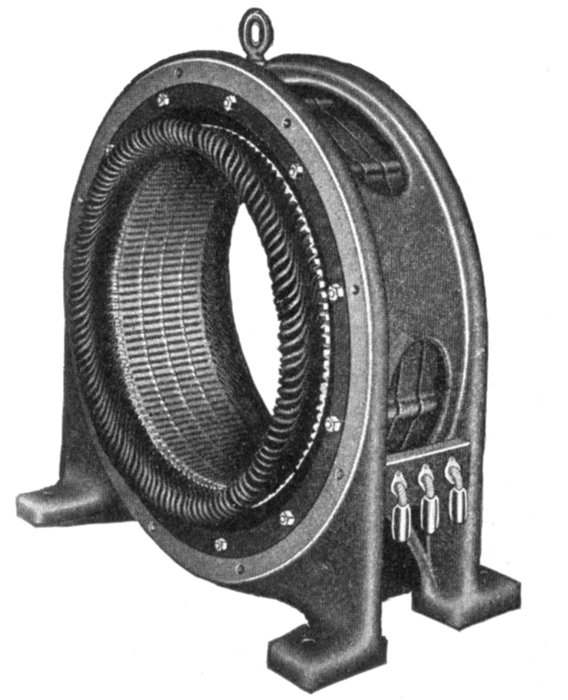

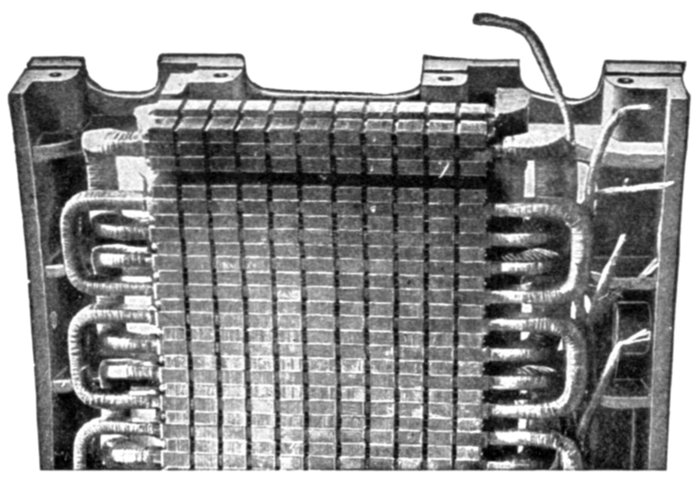

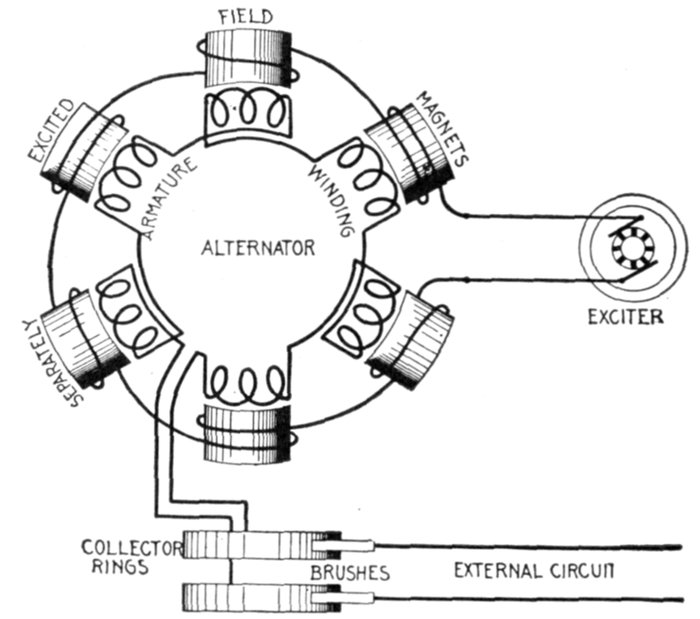

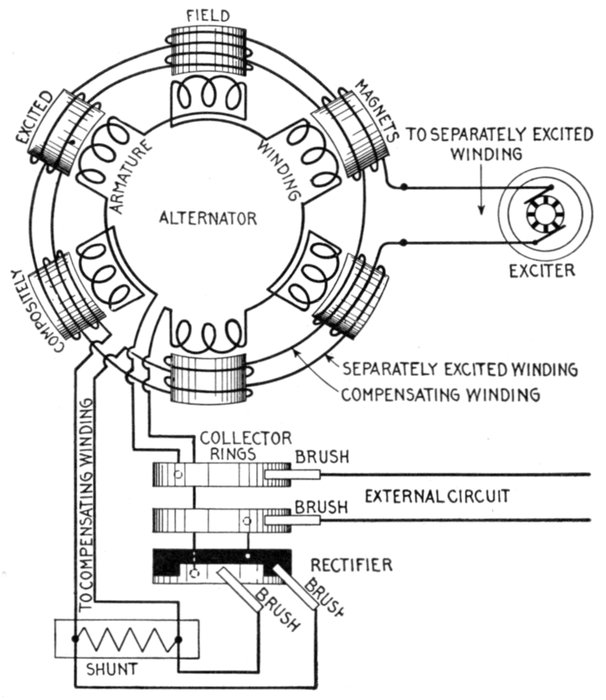

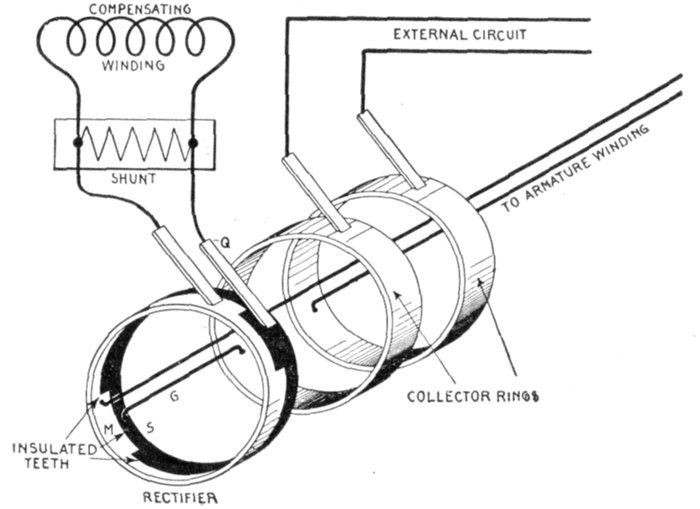

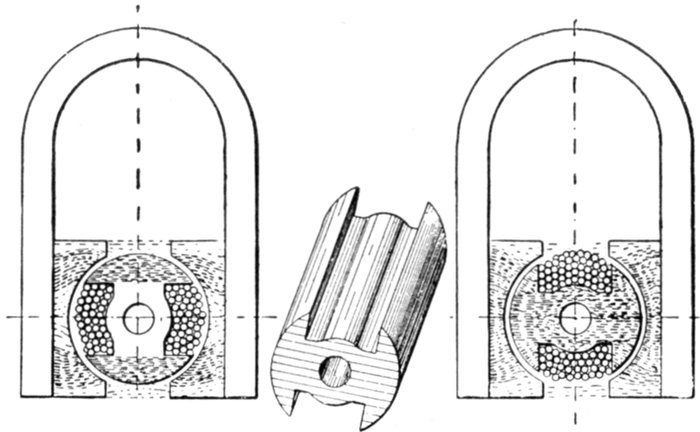

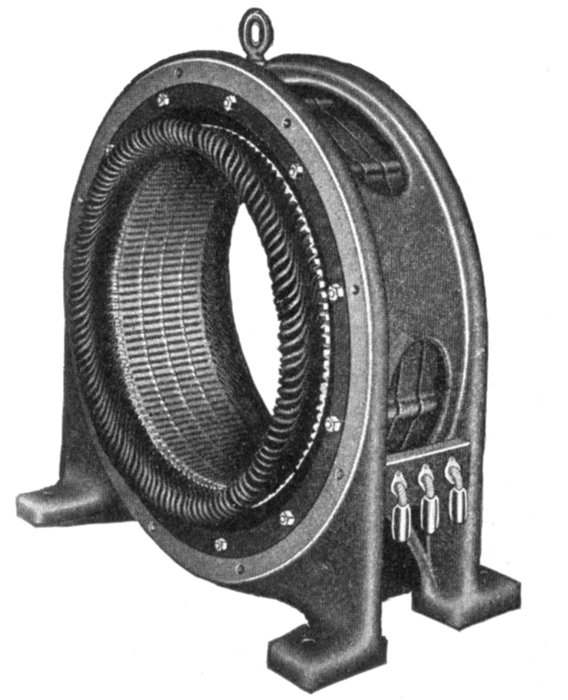

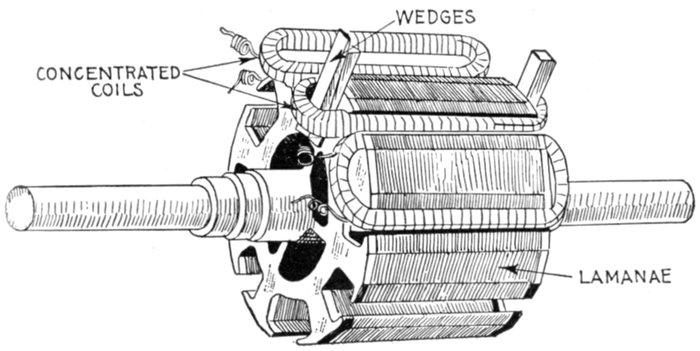

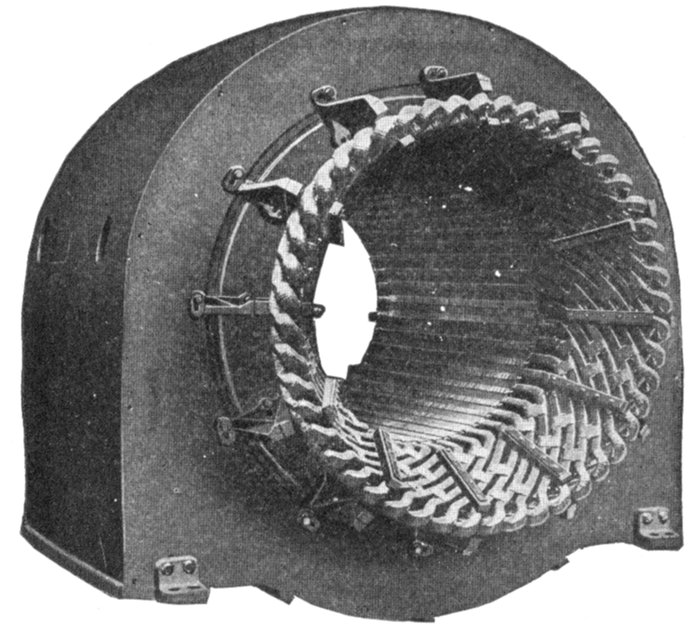

| Essential parts of an

alternator—field magnets—methods

of excitation: self-excited, separately excited,

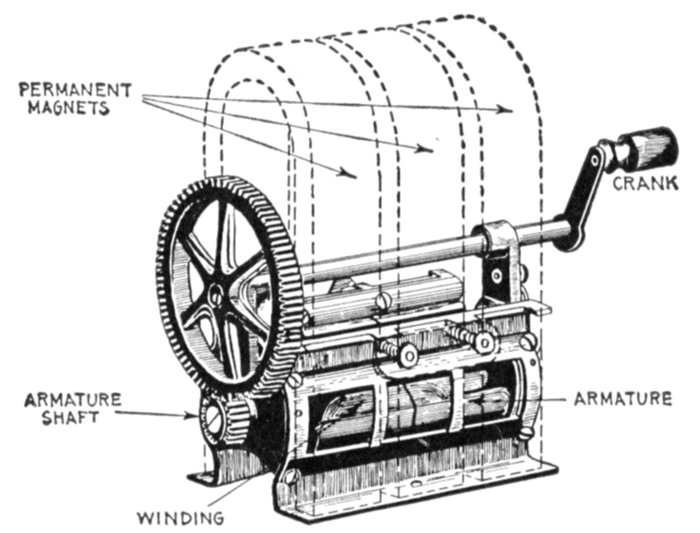

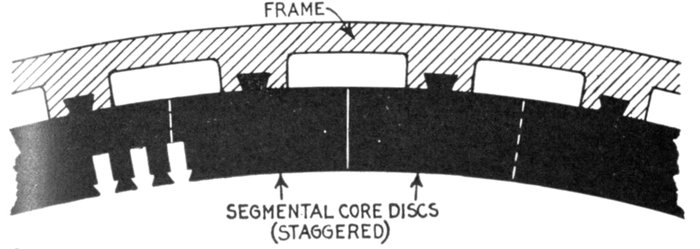

compositely excited—magneto—construction

of stationary magnets—revolving field—slip

rings—spider for large alternator—provision

for shifting armature to give access to

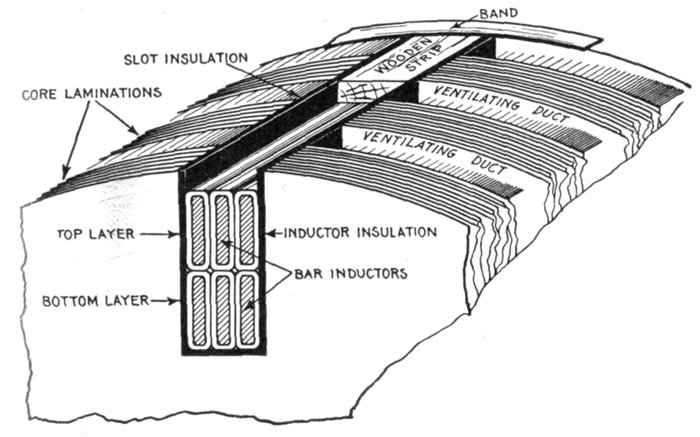

field—armatures—core

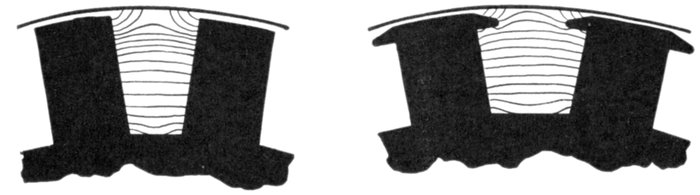

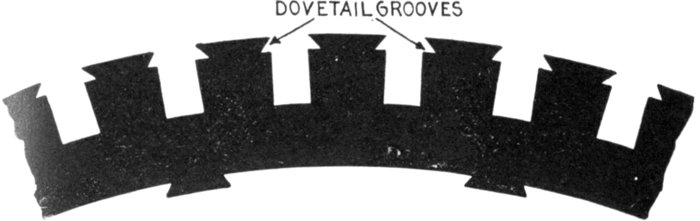

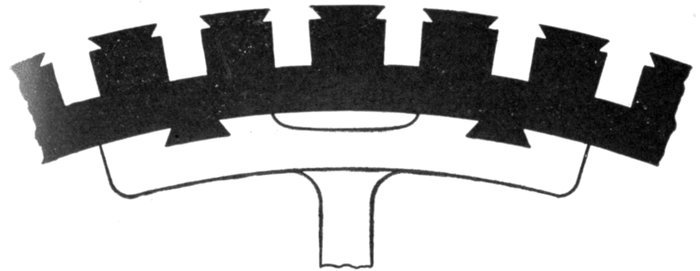

construction—advantages of slotted

core armatures—armature

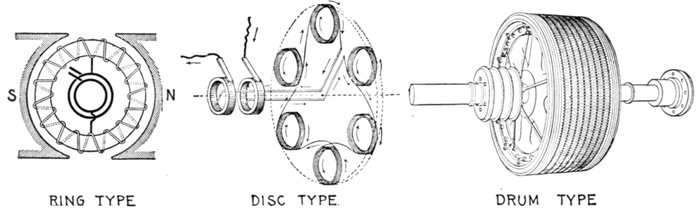

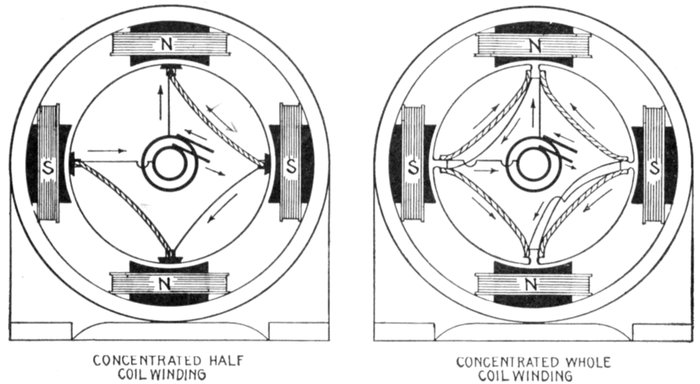

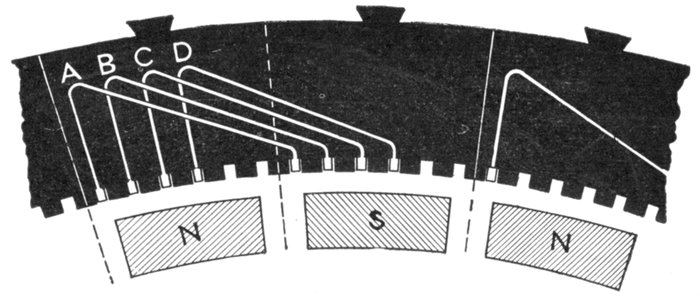

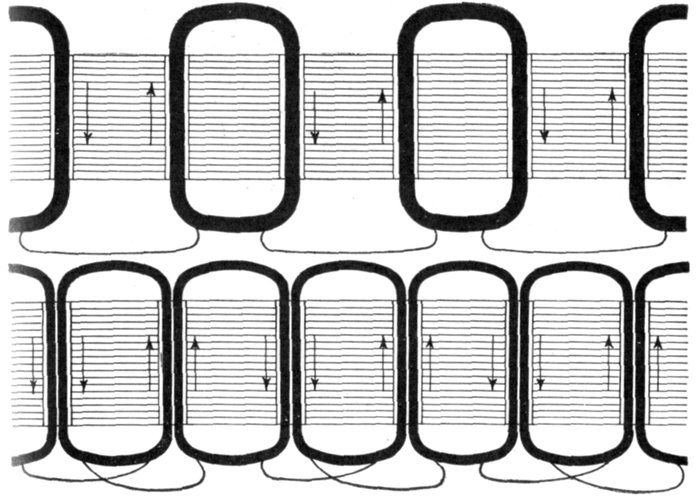

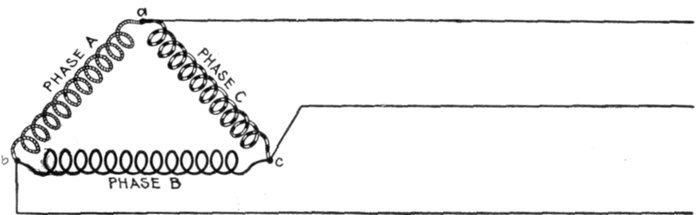

windings—classification:

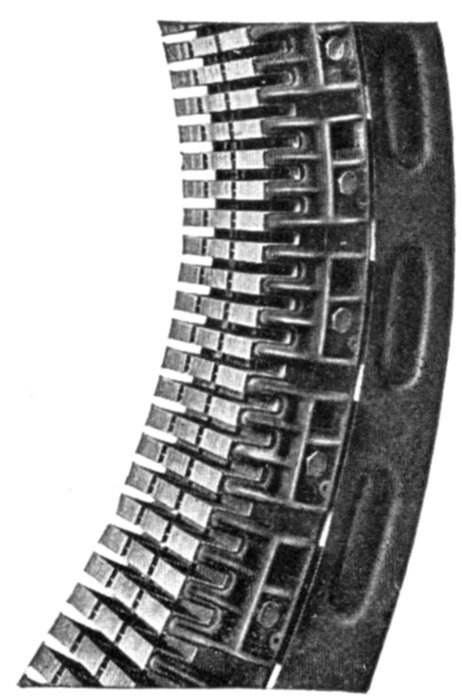

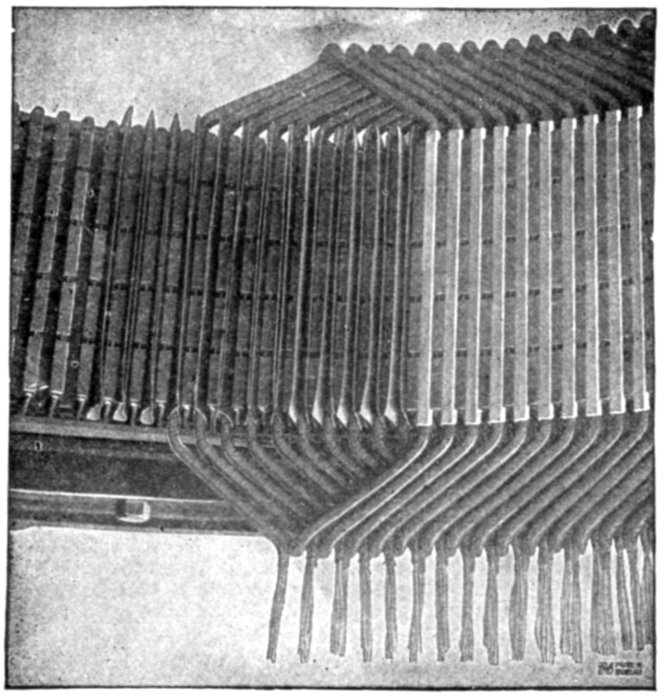

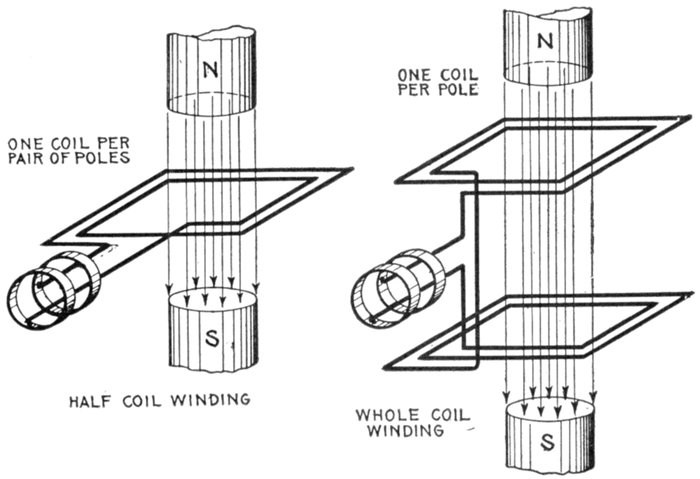

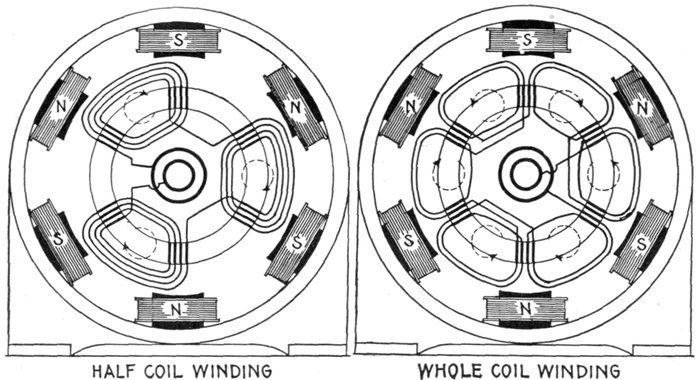

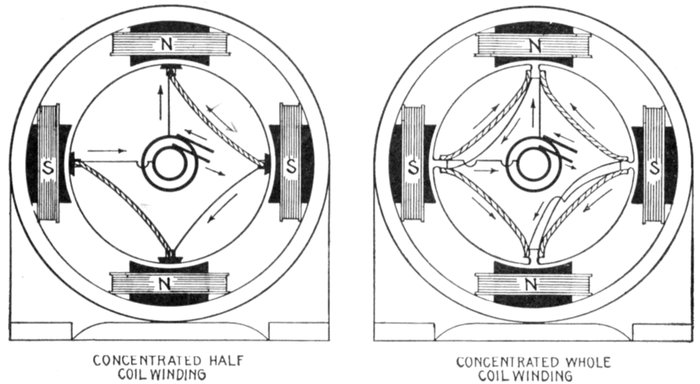

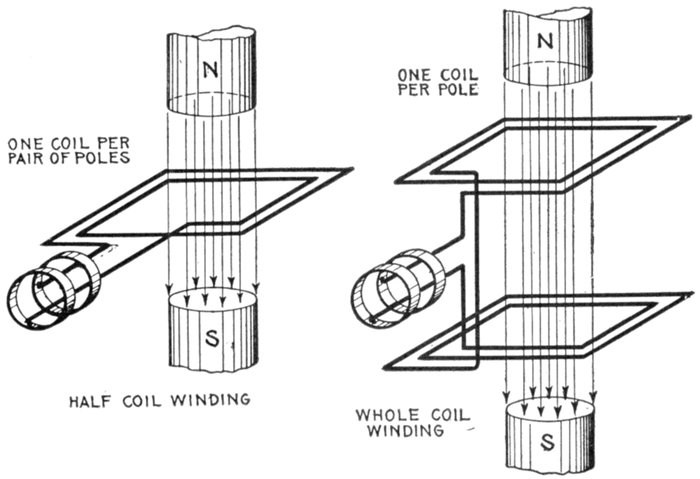

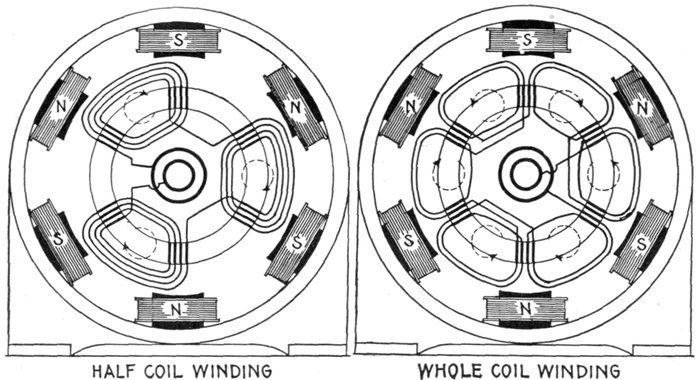

revolving and stationary windings—half coil and whole

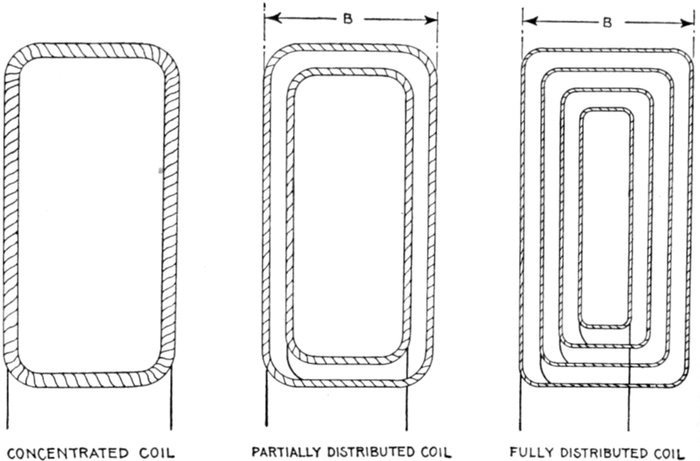

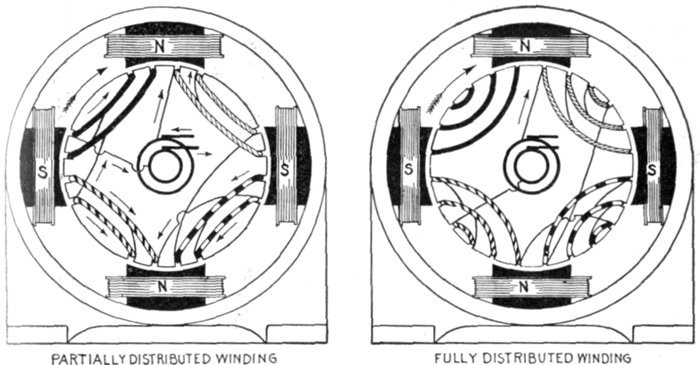

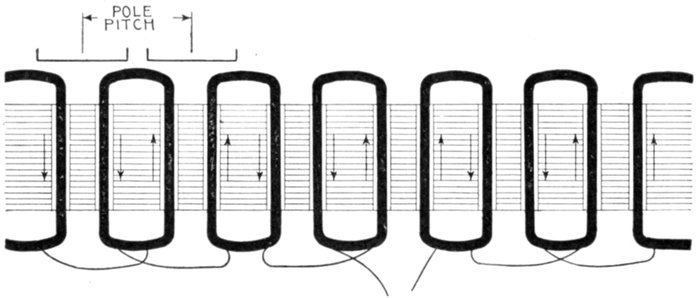

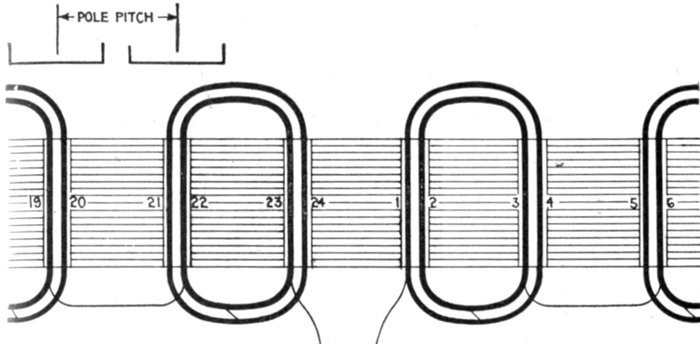

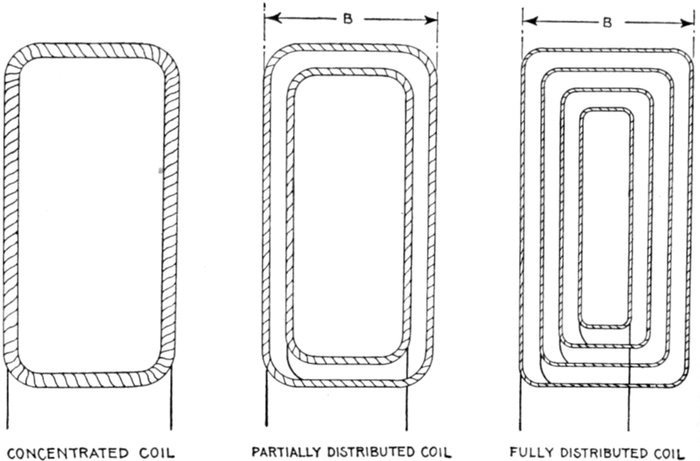

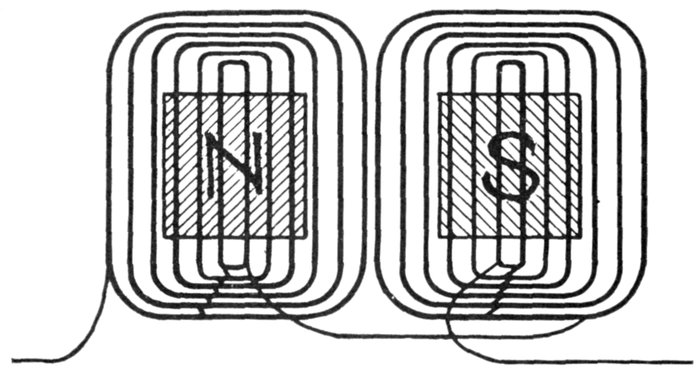

coil windings—concentrated or uni-coil

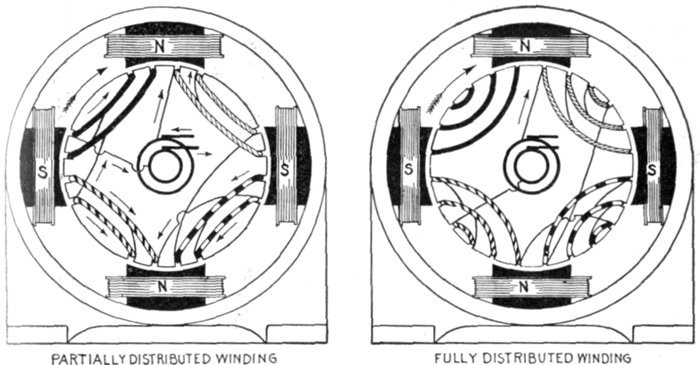

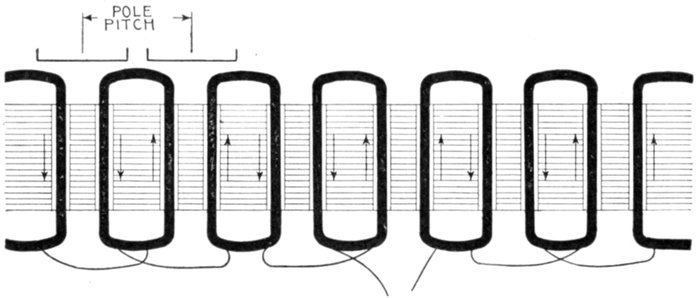

winding; features; waveform—distributed

or multi-coil windings: breadth of coil, partial and fully

distributed coils—the Kapp coefficient—general

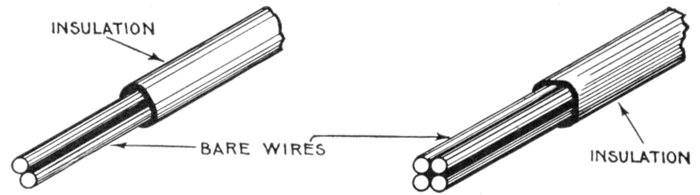

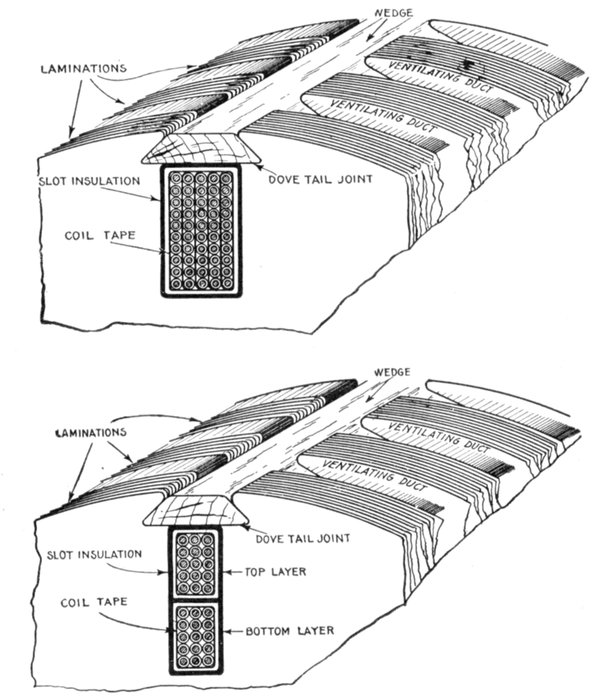

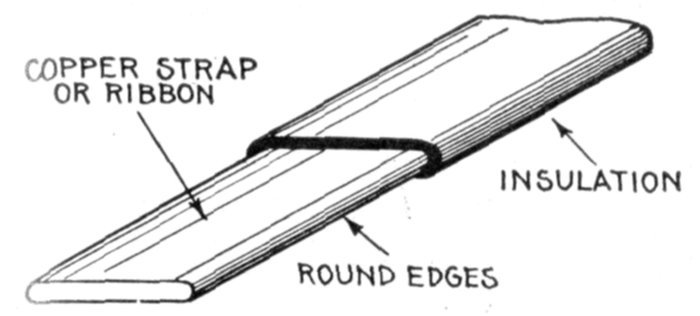

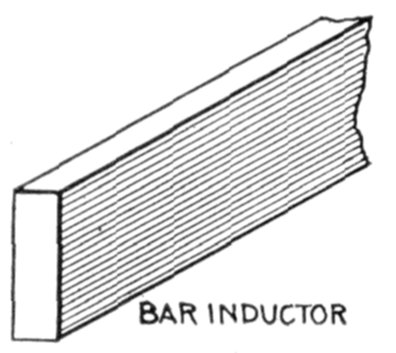

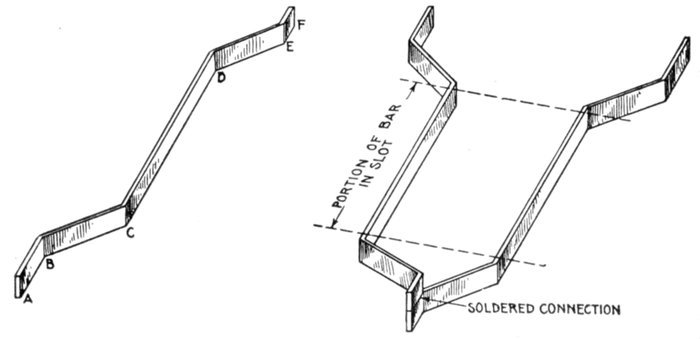

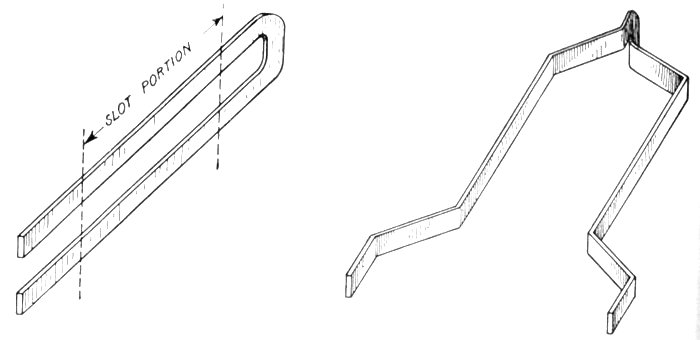

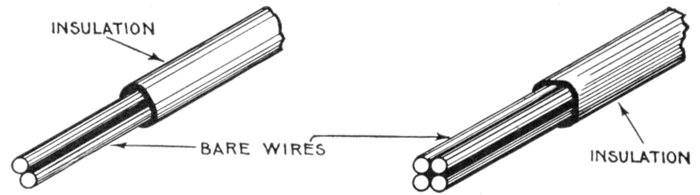

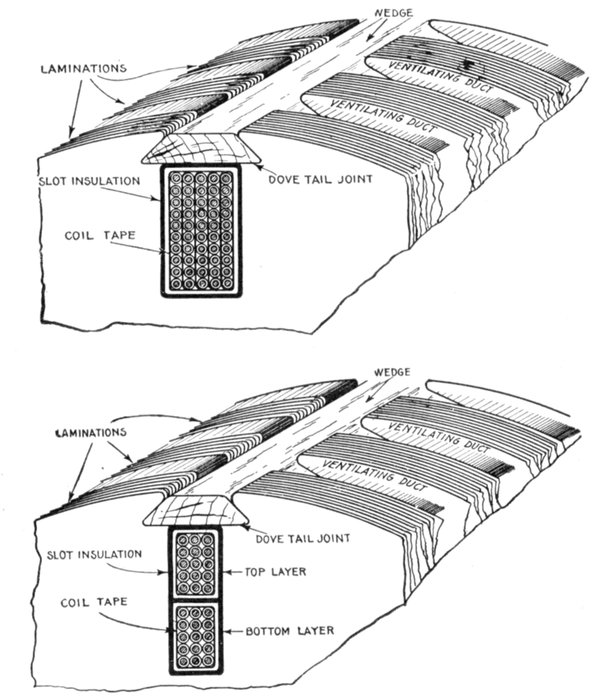

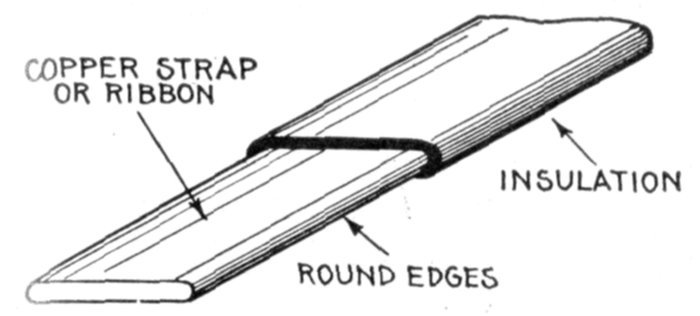

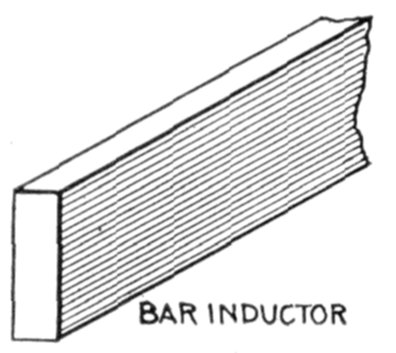

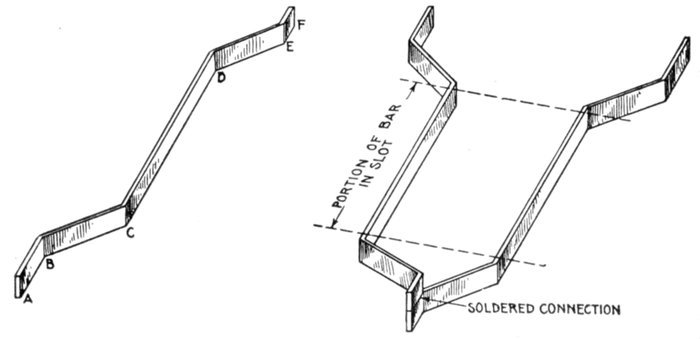

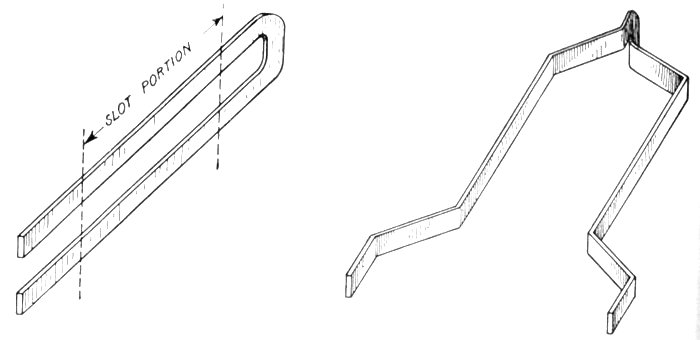

equation for voltage—wire, strap, and bar

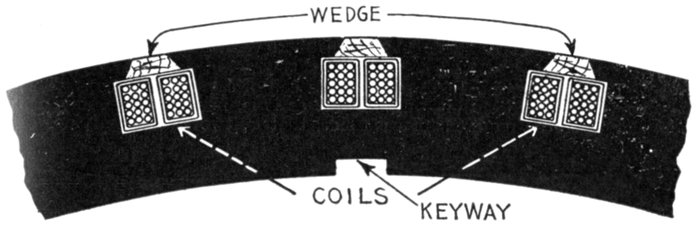

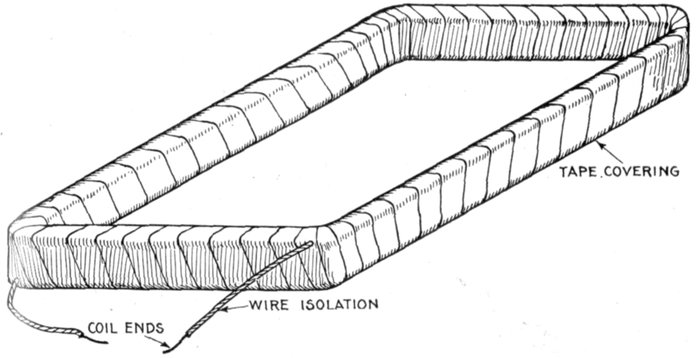

windings—condition, governing type of inductor—coil

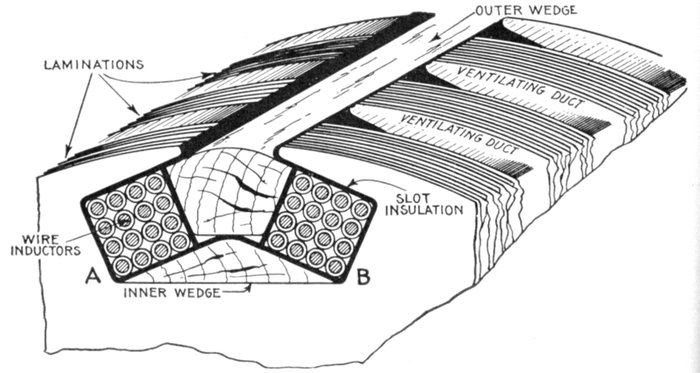

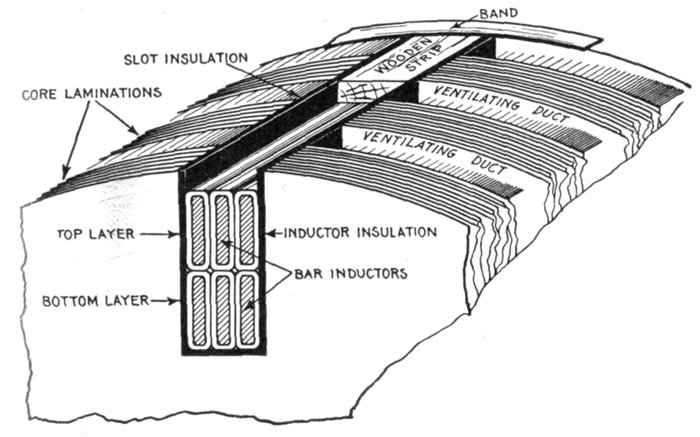

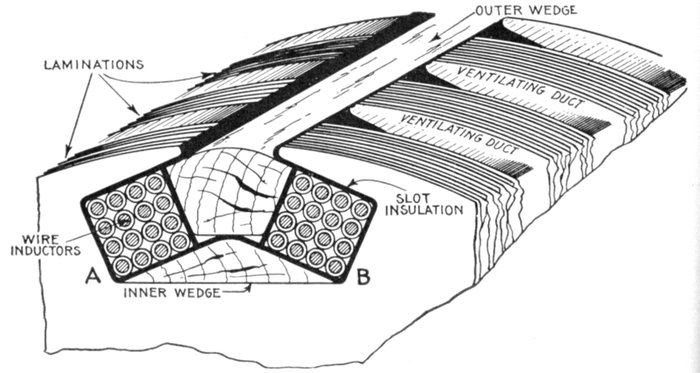

covering—single and double layer multi-wire inductors

and methods of placing them[Pg vi] on the

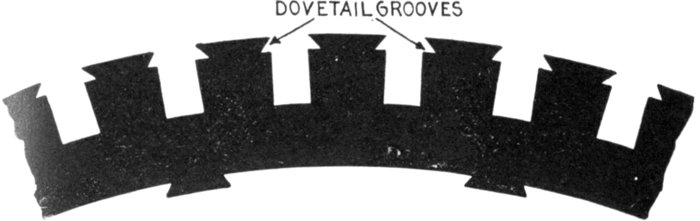

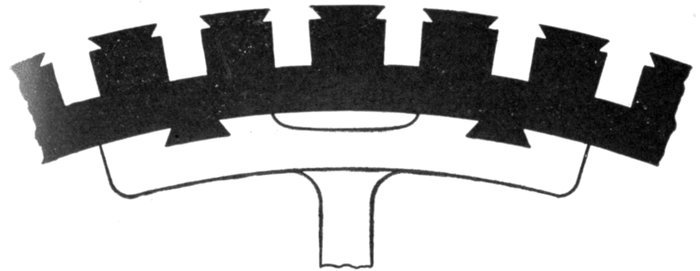

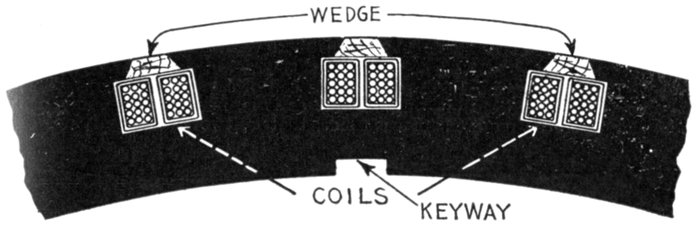

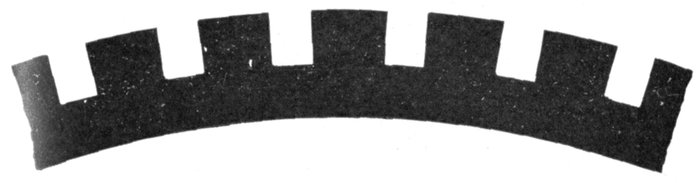

core—insulation—core

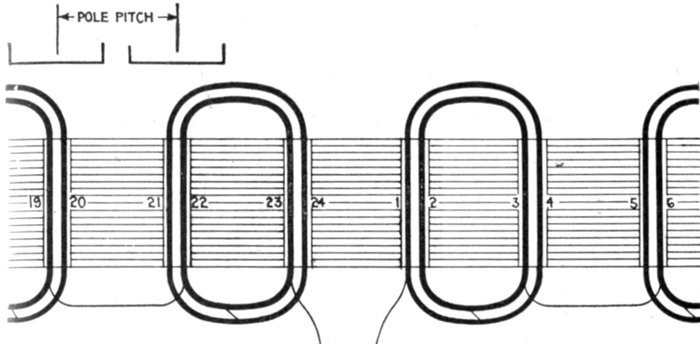

stamping—single and multi-slot windings—-

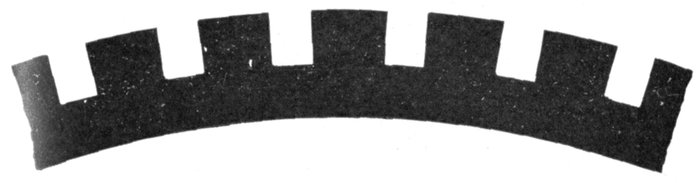

arrangement in slot of two layer bar winding—table

of relative effectiveness of windings—single

phase windings—advantage of half coil

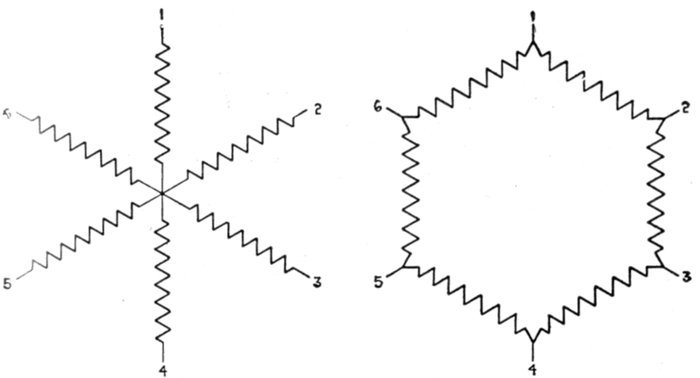

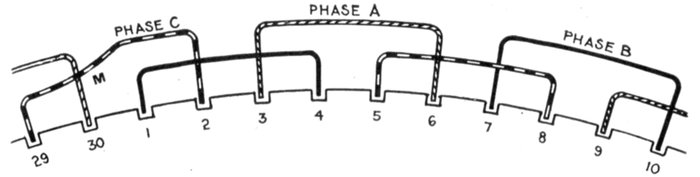

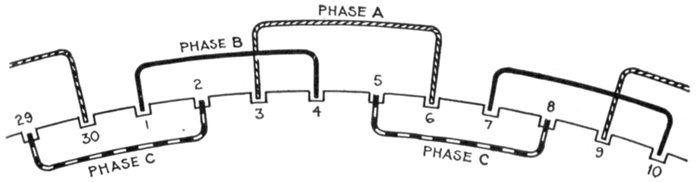

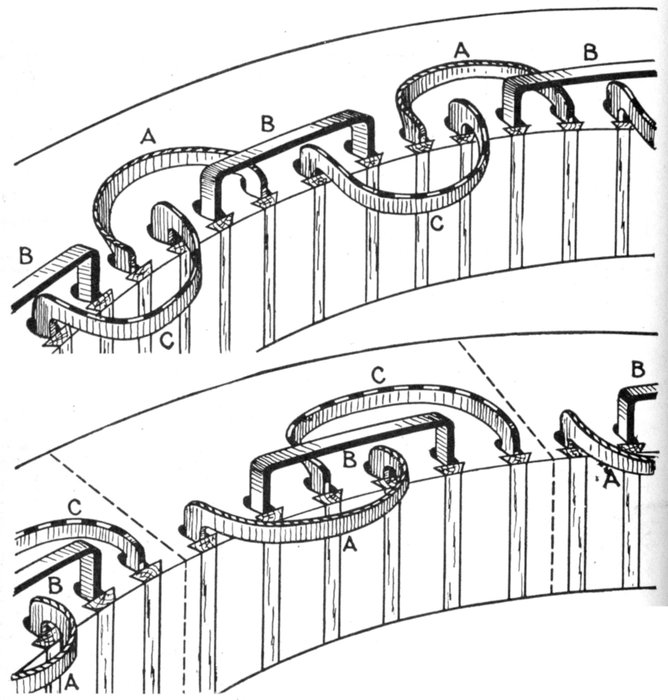

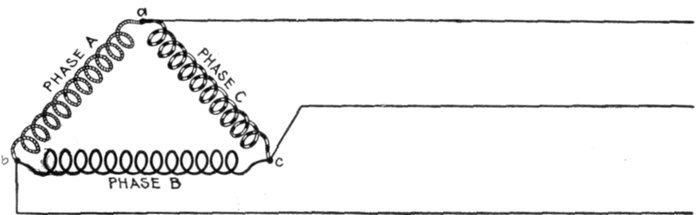

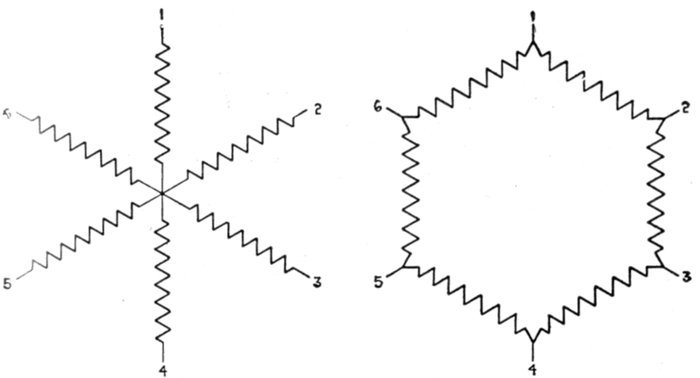

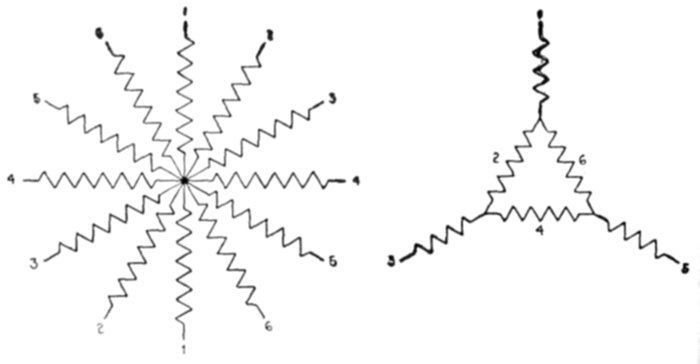

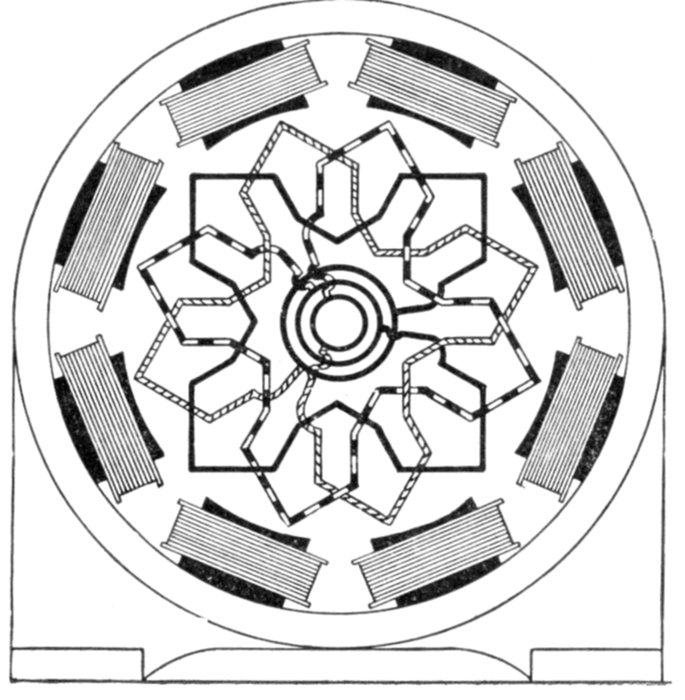

winding—two phase windings—shape

of coil ends—three phase windings—shape

of coil ends—kind of coil used with three phase

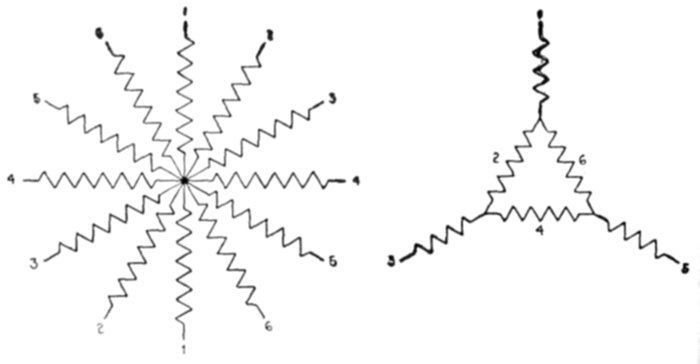

windings—grouping of phases—two

phase star connection—two phase

mesh connection—three phase star

connection—winding diagrams with star and Δ

connections—three phase Δ connection—three

phase winding with "short" coils—three phase lap

winding star connection—three phase wave winding

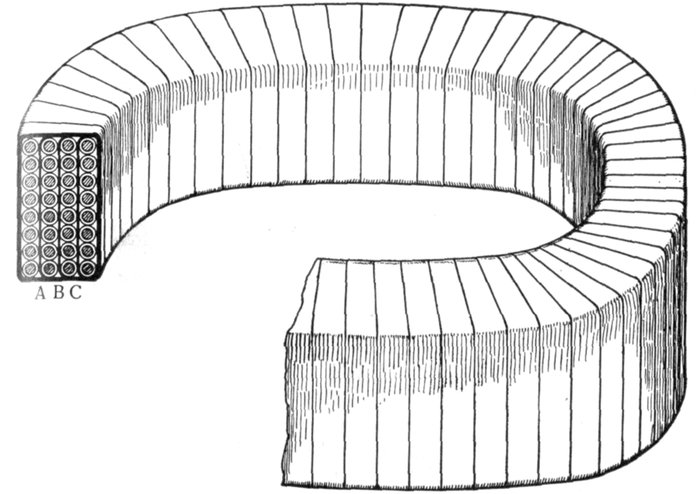

star connection—output of star and delta

connected alternators—gramme ring

armatures showing three phase star and mesh connections

with direction of currents in the coils—features

of star connection—characteristics of delta

connection—proper ends to connect to star

point—determination of path and value of

currents in delta connection—points to be noted

with Y connection—diagram of

Y connection with return wire—chain

or basket winding—skew winding—fed-in

winding—imbricated winding—spiral

winding—mummified winding—shuttle

winding—creeping winding—turbine alternator

winding: how the high voltage is obtained with so few

poles; table of frequency and revolutions—turbine

alternator construction—form of armature

generally used—two pole radial slot field—parallel

slot field—difficulty experienced with revolving

armatures—how the field design is modified to reduce

centrifugal force—examples of revolving fields. |

[Pg 997]

CHAPTER XLVI

ALTERNATING CURRENTS

The word "alternating" is used with a large number of

electrical and magnetic quantities to denote that their magnitudes

vary continuously, passing repeatedly through a definite

cycle of values in a definite interval of time.

As applied to the flow of electricity, an alternating current may

be defined as: A current which reverses its direction in a periodic

manner, rising from zero to maximum strength, returning to zero,

and then going through similar variations in strength in the opposite

direction; these changes comprise the cycle which is repeated

with great rapidity.

The properties of alternating currents are more complex than those

of continuous currents, and their behavior more difficult to predict.

This arises from the fact that the magnetic effects are of far more

importance than those of steady currents. With the latter the magnetic

effect is constant, and has no reactive influence on the current

when the latter is once established. The lines of force, however, produced

by alternating currents are changing as rapidly as the current itself,

and they thus induce electric pressures in neighboring circuits, and

even in adjacent parts of the same circuit. This inductive influence in

alternating currents renders their action very different from that of

continuous current.

Ques. What are the advantages of alternating current

over direct current?

Ans. The reduced cost of transmission by use of high voltages

and transformers, greater simplicity of generators and motors,[Pg 998]

facility of transforming from one voltage to another (either

higher or lower) for different purposes.

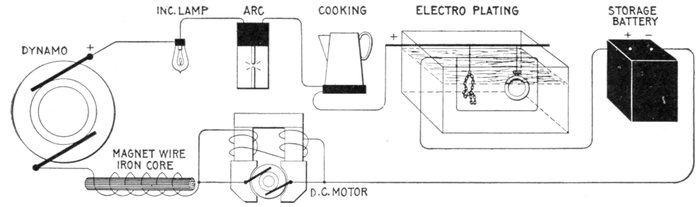

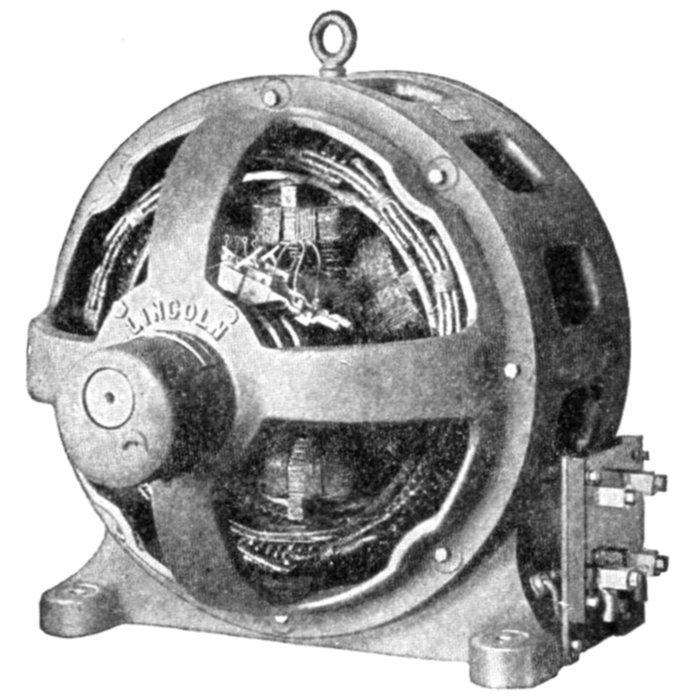

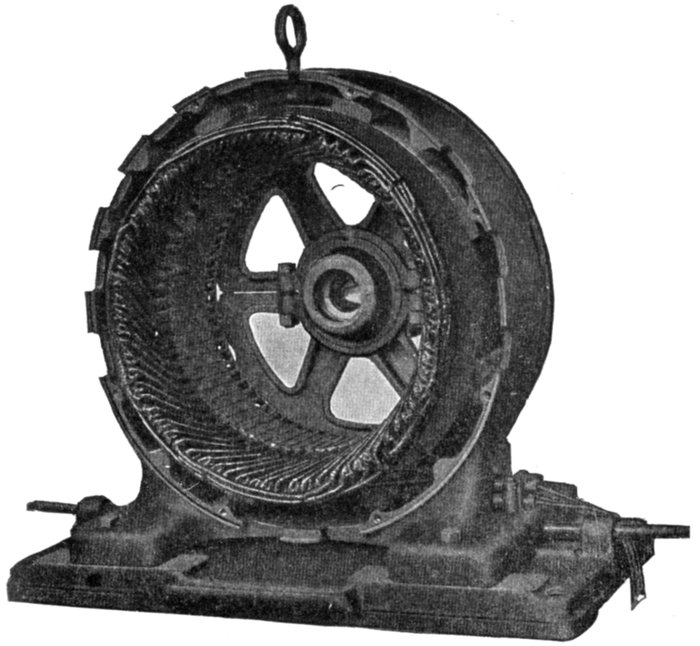

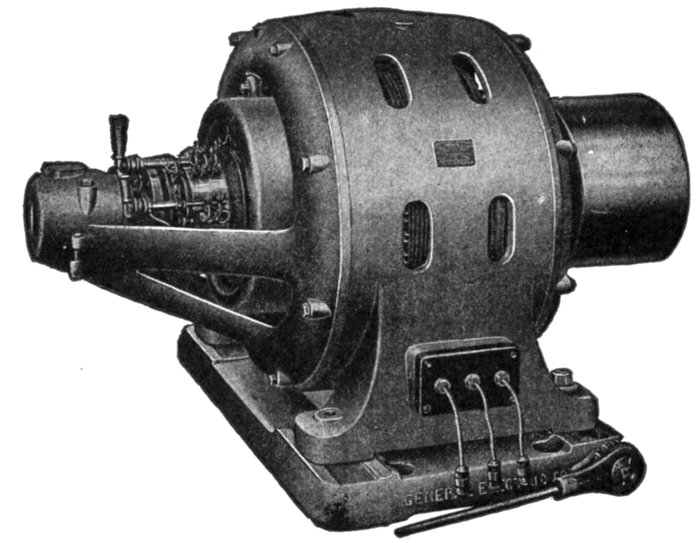

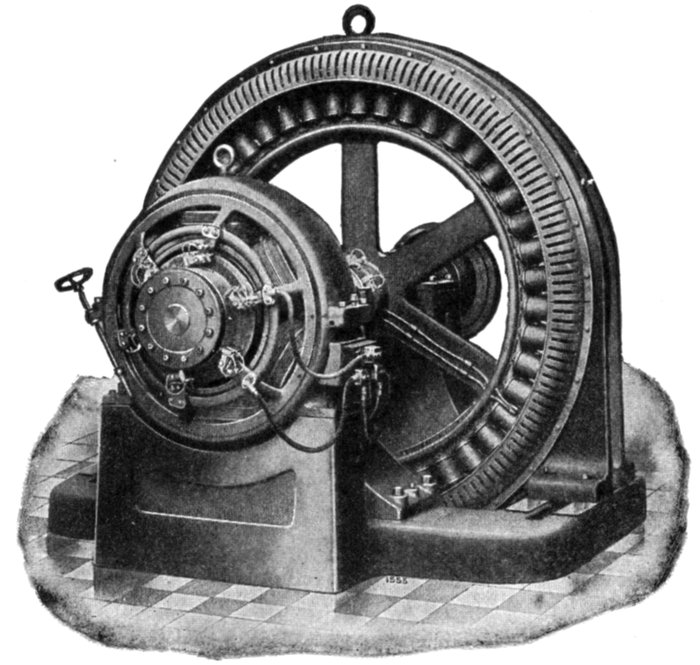

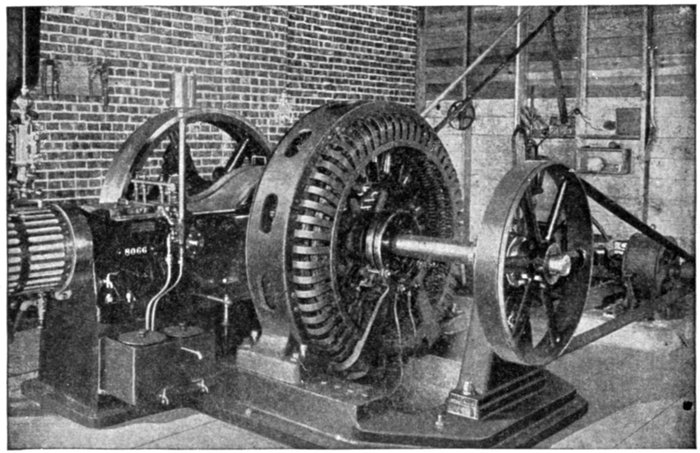

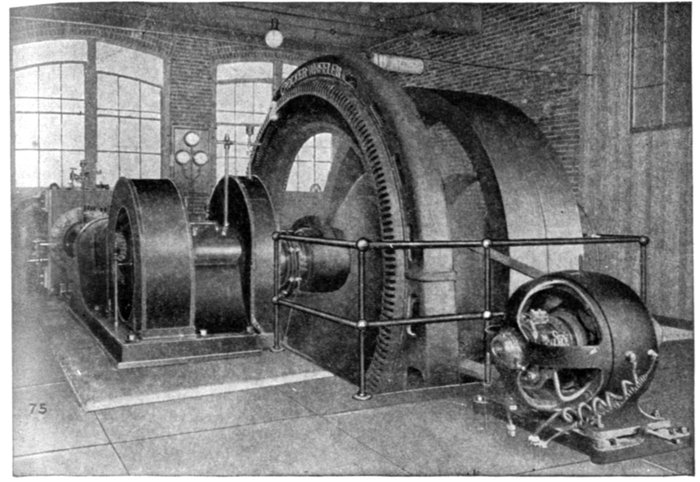

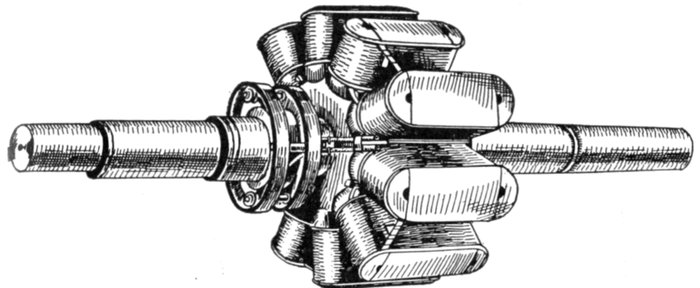

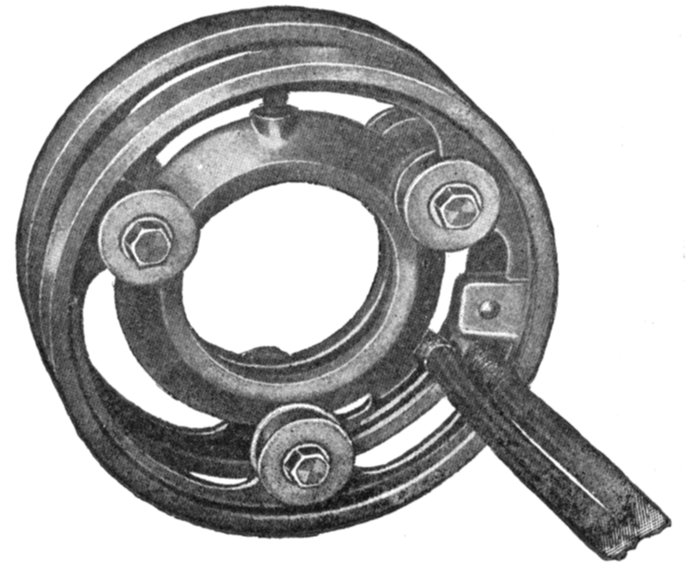

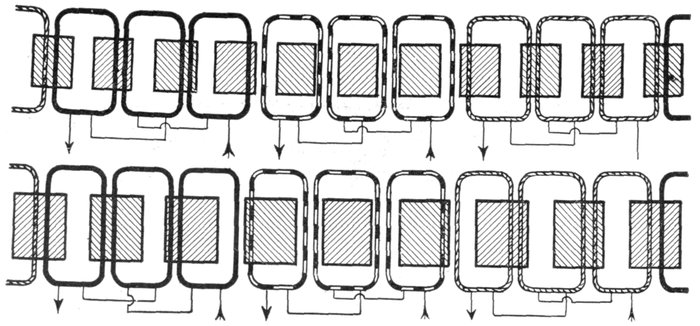

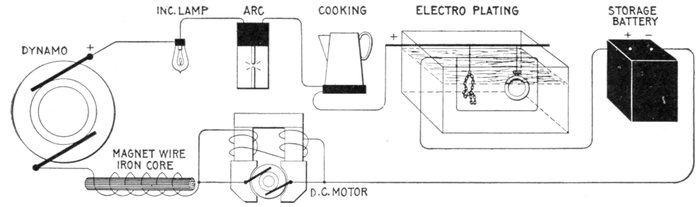

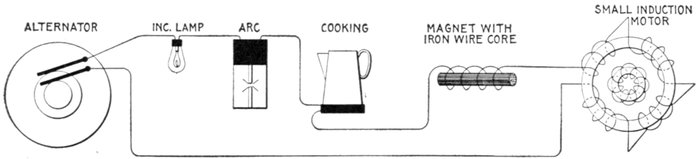

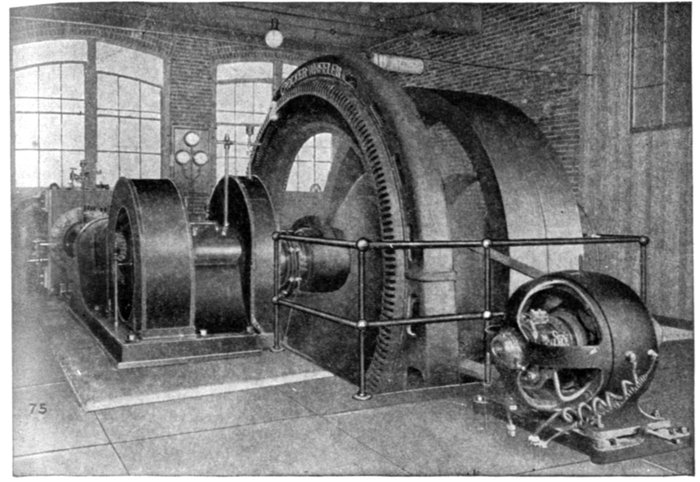

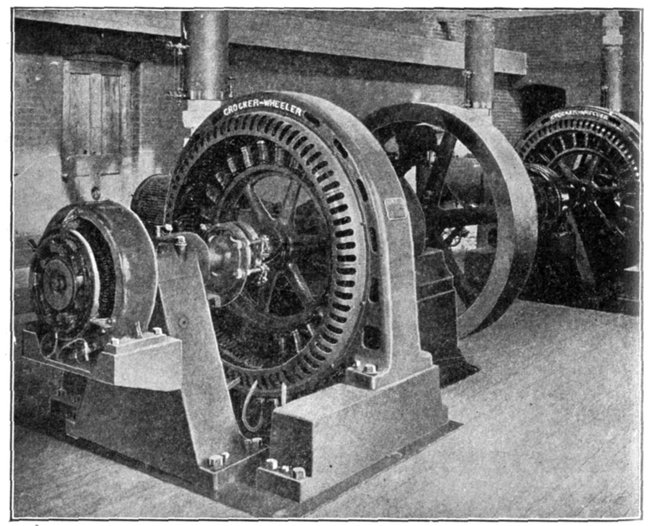

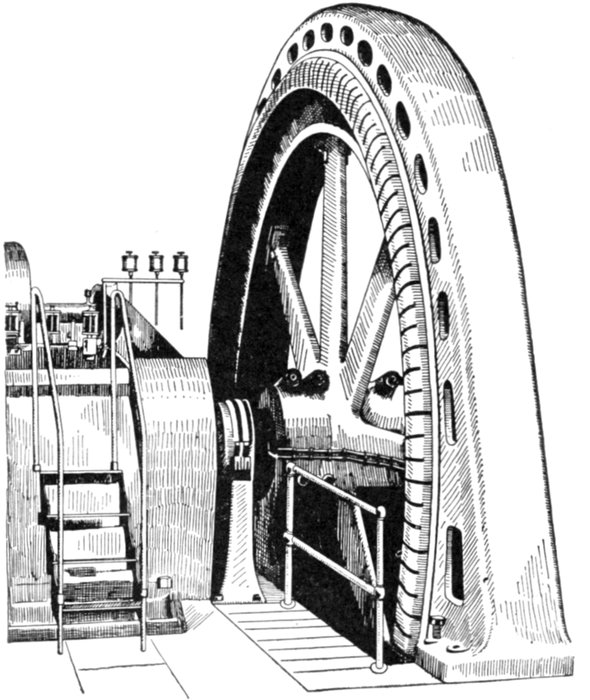

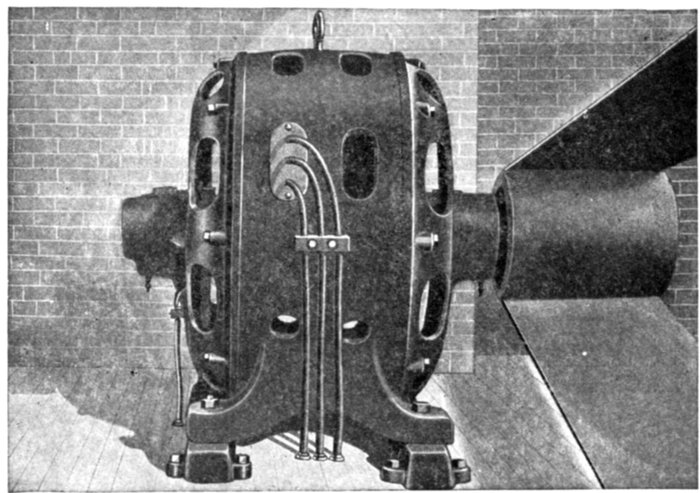

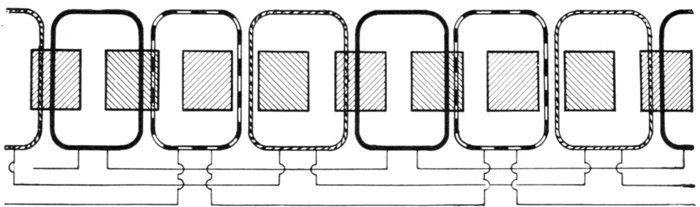

Figs. 1,206 to 1,212.—Apparatus which operates successfully on a direct current circuit. The direct current will operate incandescent

lamps, arc lamps, electric heating apparatus, electro-plating and typing bath, direct current motors; charge storage

batteries, produce electro-chemical action. It will flow through a straight wire or just as freely through the same wire when

wound over an iron bar.

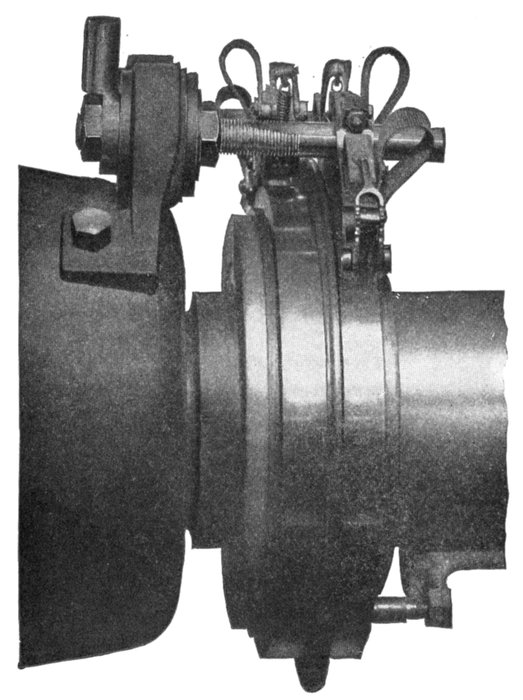

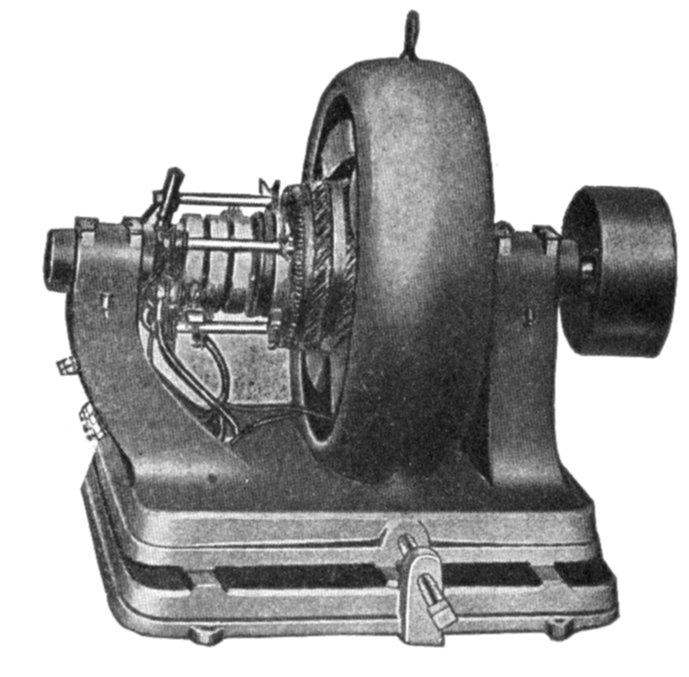

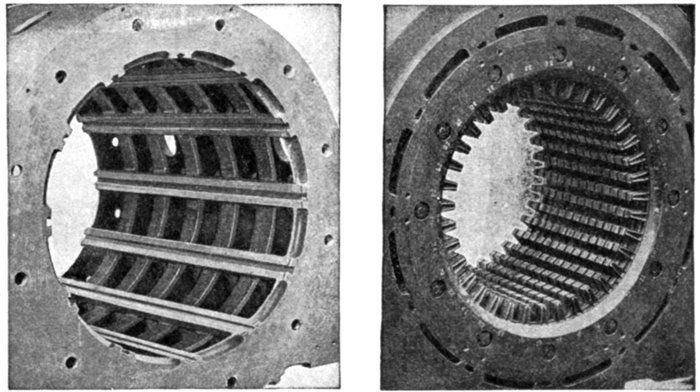

Figs. 1,213 to 1,217.—Apparatus which operates successfully on an alternating circuit. The alternating current will operate incandescent

lamps, arc lamps, electric heating apparatus, alternating current motors. It will flow through a straight wire with

slightly increased retarding effect, but if the wire be wound on an iron bar its strength is greatly reduced.

[Pg 999]

The size of wire needed to transmit a given amount of electrical energy

(watts) with a given percentage of drop, being inversely proportional

to the square of the voltage employed, the great saving in copper by the use

of alternating current at high pressure must be apparent. This advantage

can be realized either by a saving in the weight of wire required, or by

transmitting the current to a greater distance with the same weight of

copper.

In alternating current electric lighting, the primary voltage is usually

at least 1,000 and often 2,000 to 10,000 volts.

Ques. Why is alternating current used instead of

direct current on constant pressure lighting circuits?

Ans. It is due to the greater ease with which the current

can be transformed from higher to lower pressures.

Ques. How is this accomplished?

Ans. By means of simple transformers, consisting merely

of two or more coils of wire wound upon an iron core.

Since there are no moving parts, the attention required and the likelihood

of the apparatus getting out of order are small. The apparatus

necessary for direct current consists of a motor dynamo set which is

considerably more costly than a transformer and not so efficient.

Ques. What are some of the disadvantages of alternating

current?

Ans. The high pressure at which it is used renders it dangerous,

and requires more efficient insulation; alternating current

cannot be used for such purposes as electro-plating, charging

storage batteries, etc.

[Pg 1000]

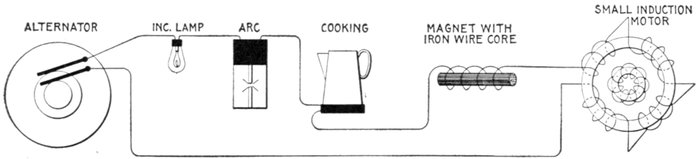

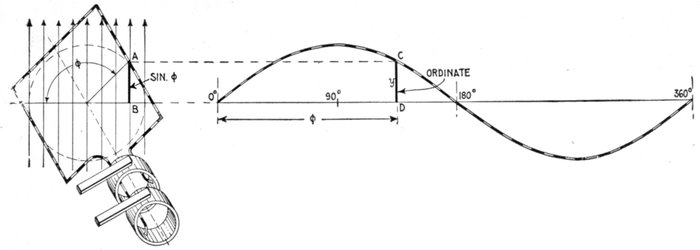

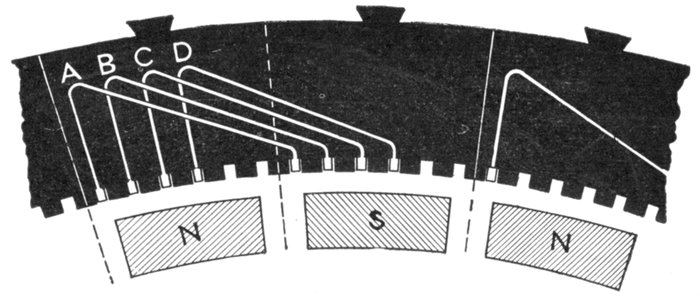

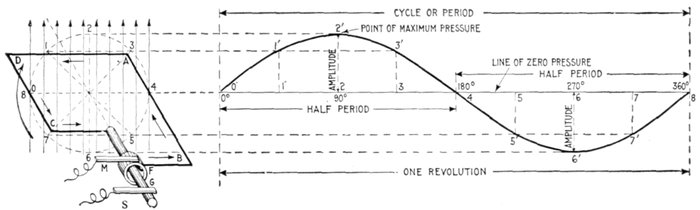

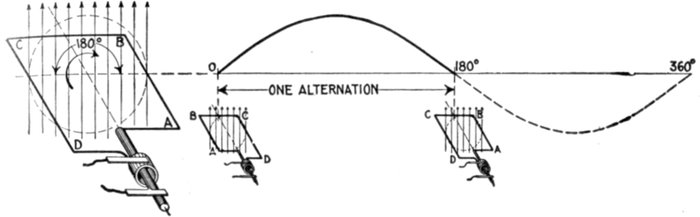

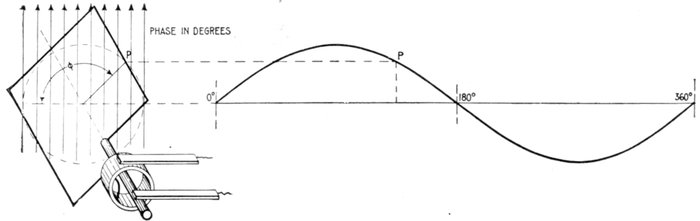

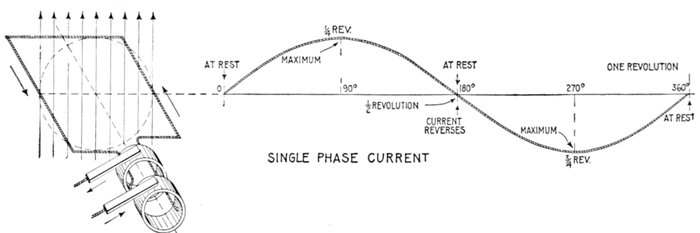

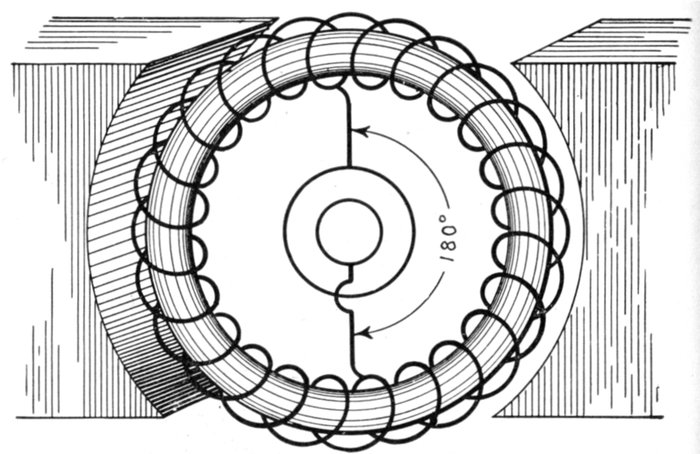

Fig. 1,218.—Application and construction of the sine curve. The sine curve is a wavelike curve used to represent the changes

in strength and direction of an alternating current. At the left of the figure is shown an elementary alternator, consisting

of a loop of wire ABCD, whose ends are attached to the ring F, and shaft G, being arranged to revolve in a uniform magnetic

field, as indicated by the vertical arrows representing magnetic lines at equidistances. The alternating current induced in

the loop is carried to the external circuit through the brushes M and S. The loop, as shown, is in its horizontal position at

right angles to the magnetic field. The dotted circle indicates the circular path described by AB or CD during the revolution

of the loop. Now, as the loop rotates, the induced electric pressure will vary in such a manner that its intensity at any

point of the rotation is proportional to the sine of the angle corresponding to that point. Hence, on the horizontal line which passes

through the center of the dotted circle, take any length as 08, and divide into any number of equal parts representing fractions

of a revolution, as 0°, 90°, 180°, etc. Erect perpendiculars at these points, and from the corresponding points on the dotted

circle project lines (parallel to 08) to the perpendiculars; these intersections give points, on the sine curve, for instance,

through 2 at the 90° point of the revolution of the loop, and projecting over to the corresponding perpendicular gives 2'2,

whose length is proportional to the electric pressure at that point. In like manner other points are obtained, and the

curved line through them will represent the variation in the electric pressure for all points of the revolution. At 90° the

pressure is at a maximum, hence by using a pressure scale such that the length of the perpendicular 2'2 for 90° will measure

the maximum pressure, the length of the perpendicular at any other point will represent the actual pressure at that point.

The curve lies above the horizontal axis during the first half of the revolution and below it during the second half, which

indicates that the current flows in one direction for a half revolution, and in the opposite direction during the remainder of

the revolution.

[Pg 1001]

Alternating Current Principles.—In the operation of a

direct current generator or dynamo, as explained in Chapter

XIII, alternating currents are generated in the armature winding

and are changed into direct current by the action of the commutator.

It was therefore necessary in that chapter, in presenting

the basic principles of the dynamo, to explain the

generation of alternating currents at length, and the graphic

method of representing the alternating current cycle by the

sine curve. In order to avoid unnecessary repetition, the reader

should carefully review the above mentioned chapter before

continuing further. The diagram fig. 168, showing the construction

and application of the sine curve to the alternating

current, is however for convenience here shown enlarged (fig. 1,218).

In the diagram the various

alternating current terms

are graphically defined.

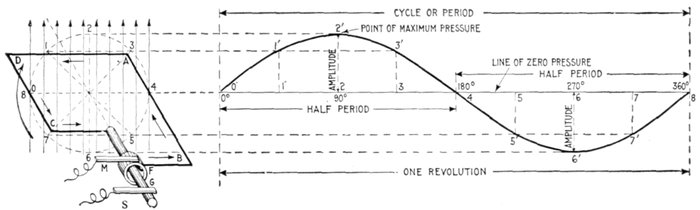

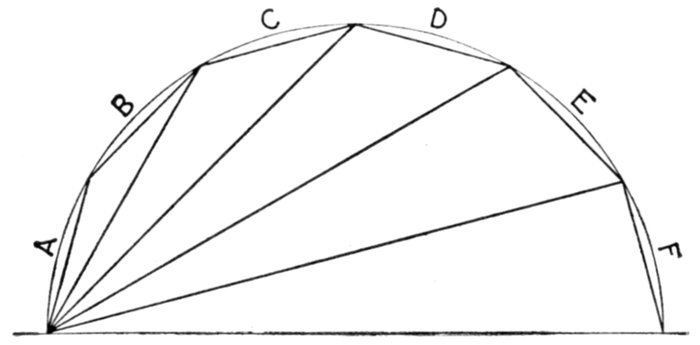

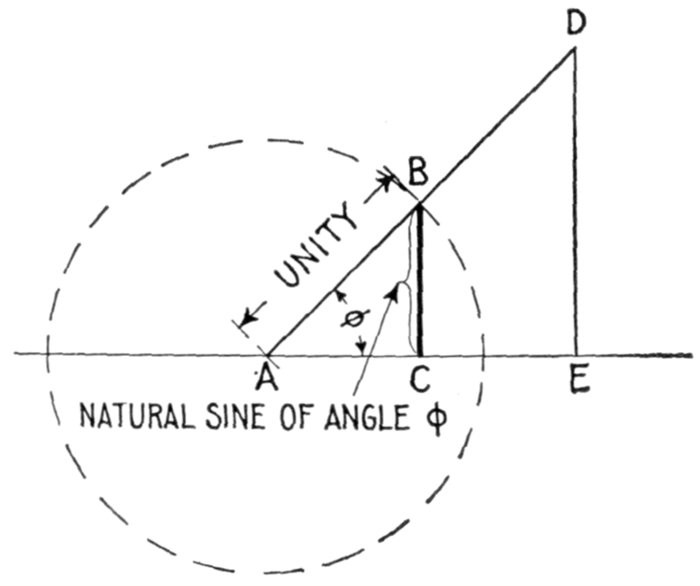

Fig. 1,219—Diagram illustrating the sine of an angle. In order to understand the sine curve,

it is necessary to know the meaning of the sine of an angle. This is defined as the ratio

of the perpendicular let fall from any point in one side of the angle to the other side divided

by the hypotenuse of the triangle thus formed. For instance, in the diagram, let AD

and AE be the two sides of the angle φ, and DE a perpendicular let fall from any point

D of the side AD to the other side AE. Then, the sine of the angle (written sin φ) = DE ÷ AD.

It is evident that if the perpendicular be let fall at a unit's distance from the

apex A, as at B,

This line BC is called the natural sine of the angle, and its values for different angles are given

in the table on page 451.

[Pg 1002]

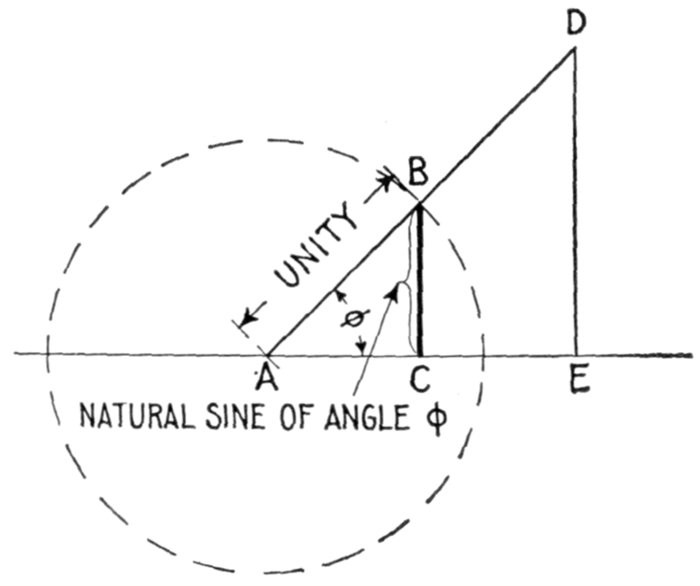

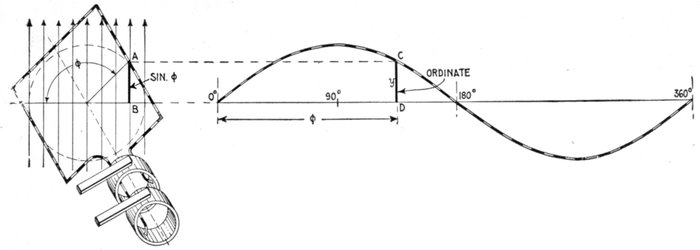

Fig. 1,220.—Diagram illustrating the equation of the sine curve: y = sin φ.

y is any ordinate, and φ, the angle which the coil makes with the

horizontal line, corresponding to the particular value of y taken.

The alternating current,

as has been explained,

rises from zero to a maximum,

falls to zero, reverses

its direction, attains a maximum

in the new direction,

and again returns to zero;

this comprises the cycle.

This series of changes

can best be represented by

a curve, whose abscissæ

represent time, or degrees

of armature rotation, and

whose ordinates, either

current or pressure. The

curve usually chosen for

this purpose is the sine

curve, as shown in fig.

1,218, because it closely

agrees with that given by

most alternators.

The equation of the sine

curve is

y = sin φ

in which y is any ordinate,

and φ, the angle of the

corresponding position of

the coil in which the current

is being generated as

illustrated in fig. 1,220.

[Pg 1003]

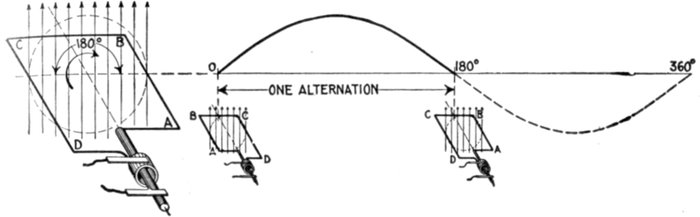

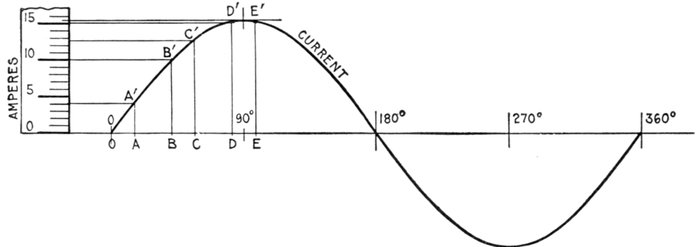

Ques. What is an alternation?

Ans. The changes which the current undergoes in rising

from zero to maximum pressure and returning back to zero;

that is, a single positive or negative "wave" or half period, as

shown in fig. 1,221.

Fig. 1,221.—Diagram showing one alternation of the current in which the latter varies from zero

to maximum and back to zero while the generating loop ABCD makes one half revolution.

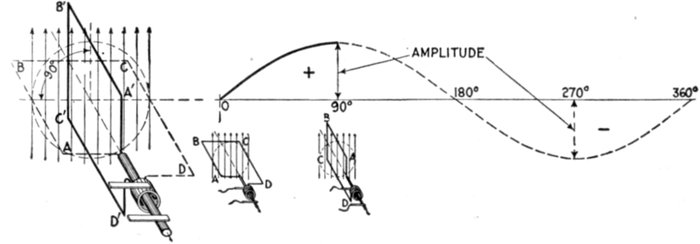

Ques. What is the amplitude of the current?

Ans. The greatest value of the current strength attained

during the cycle.

The foregoing definitions are also illustrated in fig. 1,218.

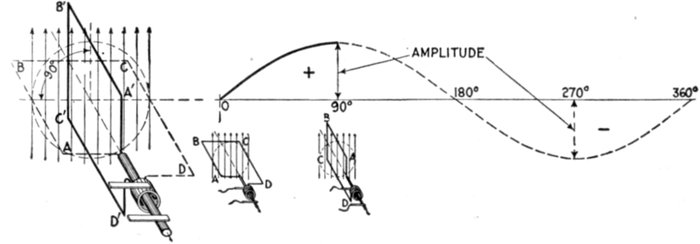

Fig. 1,222.—Diagram illustrating amplitude of the current. The current reaches its amplitude

or maximum value in one quarter period from its point of zero value, as, for instance, while

the generating loop moves from position ABCD to A'B'C'D'. At three-quarter revolution,

the current reaches its maximum value in the opposite direction.

[Pg 1004]

Ques. Define the term "period."

Ans. This is the time of one cycle of the alternating current.

Ques. What is periodicity?

Ans. A term sometimes used for frequency.

Frequency.—If a slowly varying alternating current be passed

through an incandescent lamp, the filament will be seen to vary

in brightness, following the change of current strength. If,

however, the alternations take place more rapidly than about

50 to 60 per second, the eye cannot follow the variations and the

lamp appears to burn steadily. Hence it is important to consider

the rate at which the alternations take place, or as it is called,

the frequency, which is defined as: the number of cycles per second.

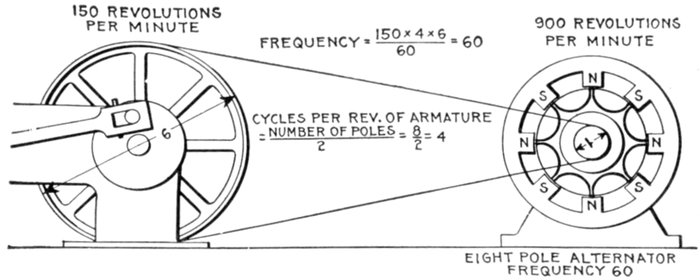

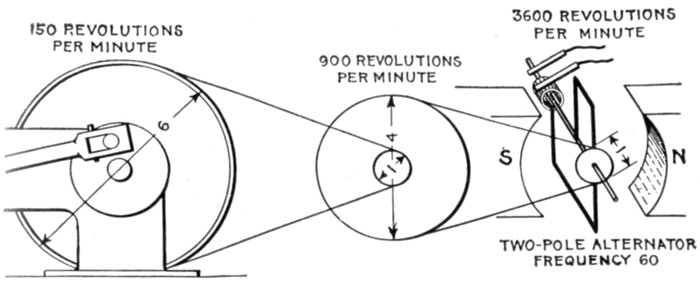

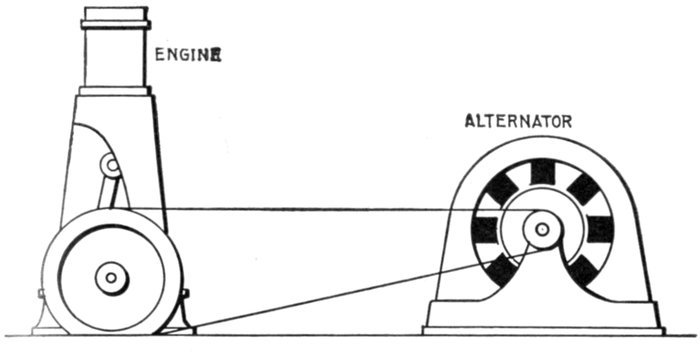

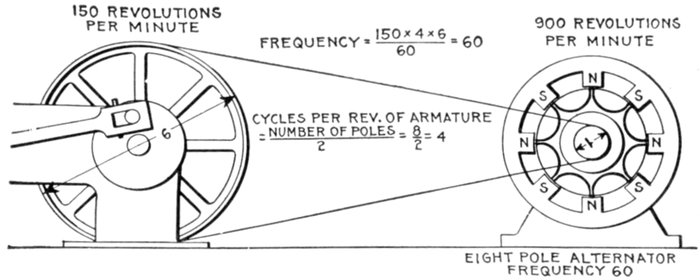

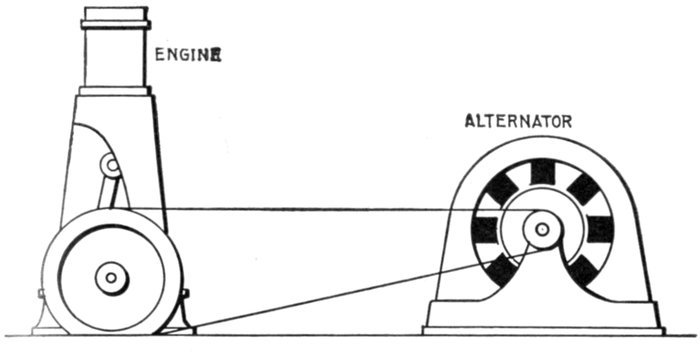

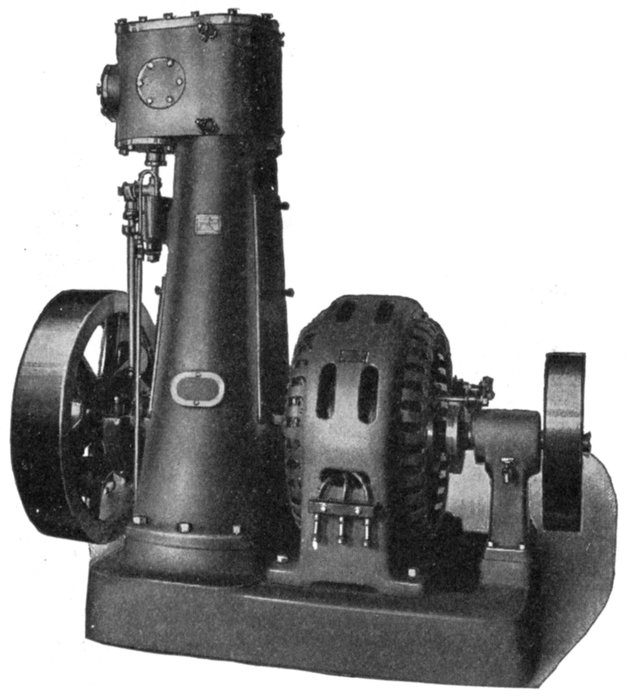

Fig. 1,223.—Diagram of alternator and engine, illustrating frequency. The frequency or

cycles per second is equal to the revolution of armature per second multiplied by one-half the

number of poles per phase. In the figure the armature makes 6 revolutions to one of the

engine; one-half the number of poles = 8 ÷ 2 = 4, hence frequency = (150 × 4 × 6) ÷ 60

= 60. The expression in the parenthesis gives the cycles per minute, and dividing by 60,

the cycles per second.

In a two pole machine, the frequency is the same as the number

of revolutions per second, but in multipolar machines, it is

greater in proportion to the number of pairs of poles per phase.

[Pg 1005]

Thus, in an 8 pole machine, there will be four cycles per revolution.

If the speed be 900 revolutions per minute, the frequency is

The symbol ~ is read "cycles per second."

Ques. What frequencies are used in commercial

machines?

Ans. The two standard frequencies are 25 and 60 cycles.

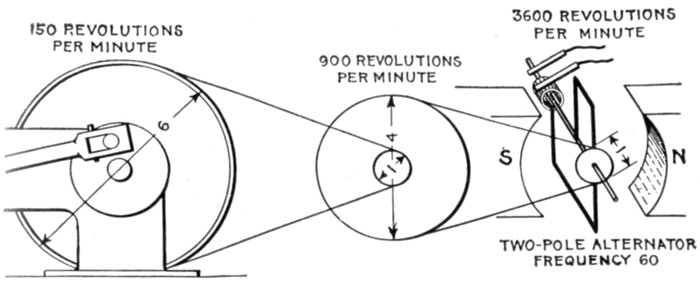

Fig. 1,224—Diagram answering the question: Why are alternators always built multipolar?

They are made multipolar because it is desirable that the frequency be high. It is evident

from the figure that to obtain high frequency would require too many revolutions of the

armature of a bipolar machine for mechanical safety—especially in large alternators.

Moreover a double reduction gear in most cases would be necessary, adding complication

to the drive. Comparing the above illustration with fig. 1,223, shows plainly the reason

for multipolar construction.

Ques. For what service are these frequencies adapted?

Ans. The 25 cycle frequency is used for conversion to direct

current, for alternating current railways, and for machines of

large size; the 60 cycle frequency is used for general distribution

for lighting and power.

The frequency of 40 cycles, which once was introduced as a compromise

between 25 and 60 has been found not desirable, as it is somewhat

low for general distribution, and higher than desirable for conversion

to direct current.

[Pg 1006]

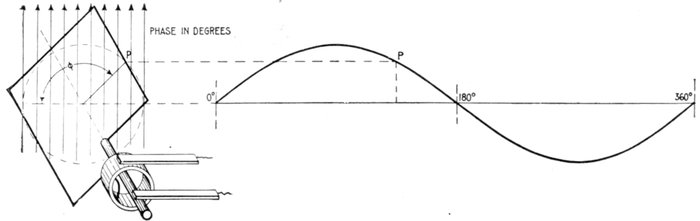

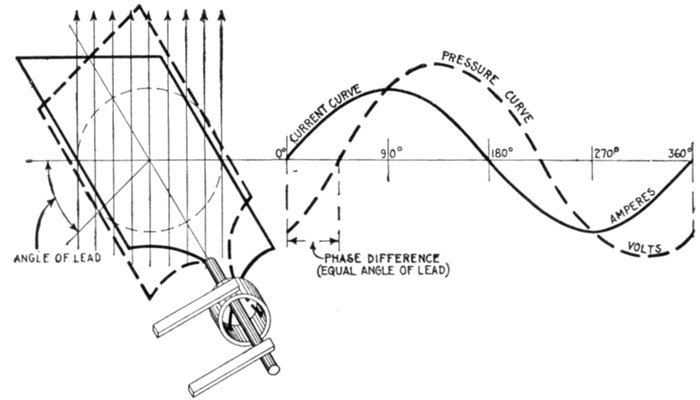

Fig. 1,225.—Diagram illustrating "phase." In wave, vibratory, and simple harmonic motion, phase may be defined as: the

portion of one complete vibration, measured either in angle or in time, that any moving point has executed.

Ques. What are

the advantages of

low frequency?

Ans. The number of

revolutions of the rotor

is correspondingly low;

arc lamps can be more

readily operated; better

pressure regulation;

small motors such as

fan motors can be operated

more easily from

the circuit.

Phase.—As applied

to an alternating current,

phase denotes the

angle turned through by

the generating element

reckoned from a given

instant. Phase is usually

measured in degrees

from the initial position

of zero generation.

If in the diagram fig.

1,225, the elementary

armature or loop be the

generating element, and

the curve at the right

be the sine curve representing

the current,

then the phase of any

point p will be the angle φ

or angle moved through

from the horizontal line,

the starting point.

[Pg 1007]

Ques. What is phase difference?

Ans. The angle between the phases of two or more alternating

current quantities as measured in degrees.

Ques. What is phase displacement?

Ans. A change of phase of an alternating pressure or current.

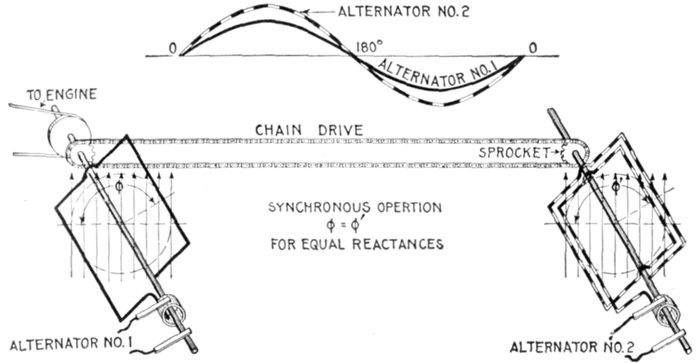

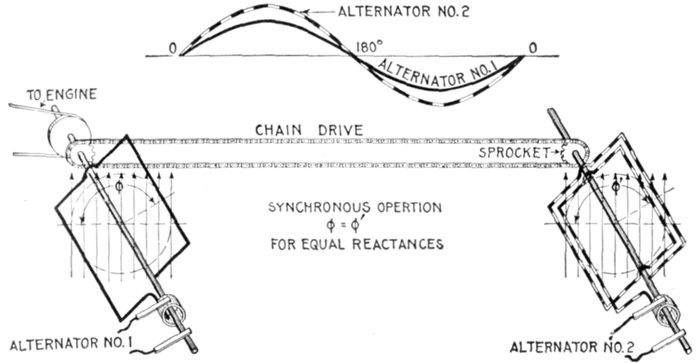

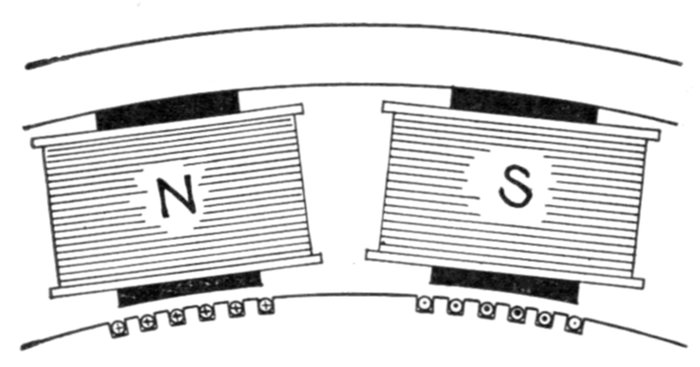

Figs. 1,226 and 1,227.—Diagram and sine curves illustrating synchronism. If two alternators,

with coils in parallel planes, be made to rotate at the same speed by connecting

them with chain drive or equivalent means, they will then be "in synchronism" that is,

the alternating pressure or current in one will vary in step with that in the other. In

other words, the cycles of one take place with the same frequency and at the same time

as the cycles of the other as indicated by the curves, fig. 1,226. It should be noted that

the maximum values are not necessarily the same but the maximum and zero values

must occur at the same time in both machines, and the maximum value must be of the

same sign. If the waves be distorted the maximum values may not occur simultaneously.

See fig. 1,348.

Synchronism.—This term may be defined as: the simultaneous

occurrence of any two events. Thus two alternating currents

or pressures are said to be "in synchronism" when they

have the same frequency and are in phase.

Ques. What does the expression "in phase" mean?

Ans. Two alternating quantities are said to be in phase,

when there is no phase difference between; that is when the

angle of phase difference equals zero.

[Pg 1008]

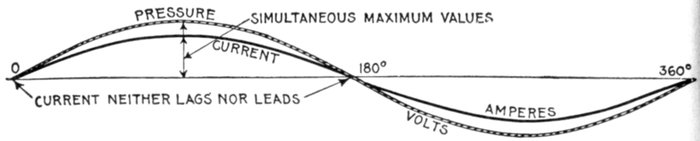

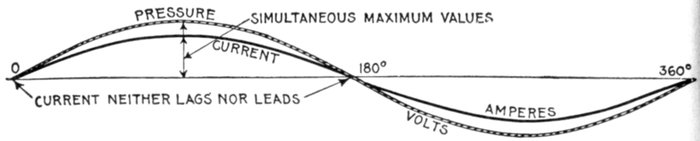

Thus the current is said to be in phase with the pressure when it

neither lags nor leads, as in fig. 1,228.

A rotating cylinder, or the movement of an index or trailing arm is

brought into synchronism with another rotating cylinder or another

index or trailing arm, not only when the two are moving with exactly

the same speed, but when in addition they are simultaneously moving

over similar portions of their respective paths.

Fig. 1,228—Pressure and current curves illustrating the term "in phase." The current

is said to be in phase with the pressure when it neither lags nor leads.

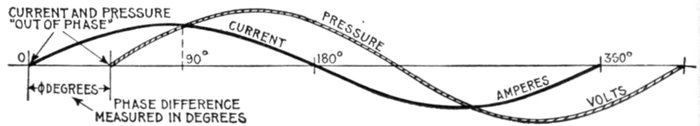

When there is phase difference, as between current and

pressure, they are said to be "out of phase" the phase difference

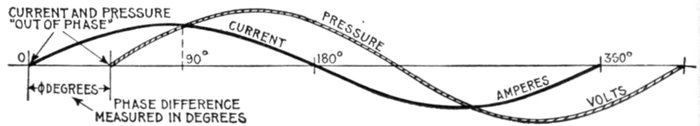

being measured as in fig. 1,229 by the angle φ.

Fig. 1,229—Pressure and current curves illustrating the term "out of phase." The current

is said to be out of phase with the pressure when it either lags or leads, that is when the

current is not in synchronism with the pressure. In practice the current and pressure

are nearly always out of phase.

When the phase difference is 90° as in fig. 1,231 or 1,232, the two

alternating quantities are said to be in quadrature; when it is 180°, as

in fig. 1,233, they are said to be in opposition.

When they are in quadrature, one is at a maximum when the other

is at zero; when they are in opposition, one reaches a positive maximum

when the other reaches a negative minimum, being at each instant

opposite in sign.

Ques. What is a departure from synchronism called?

Ans. Loss of synchronism.

[Pg 1009]

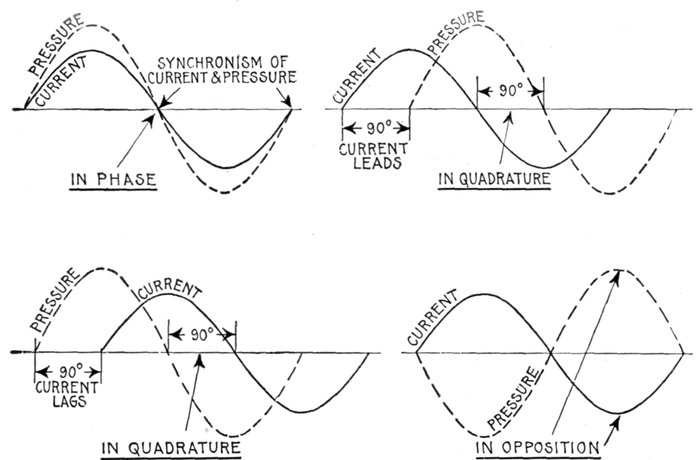

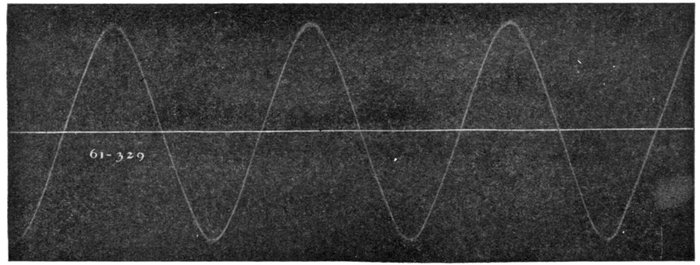

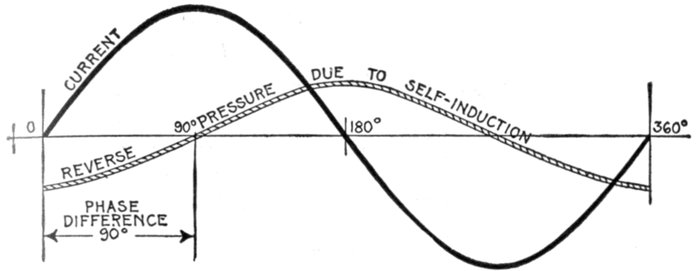

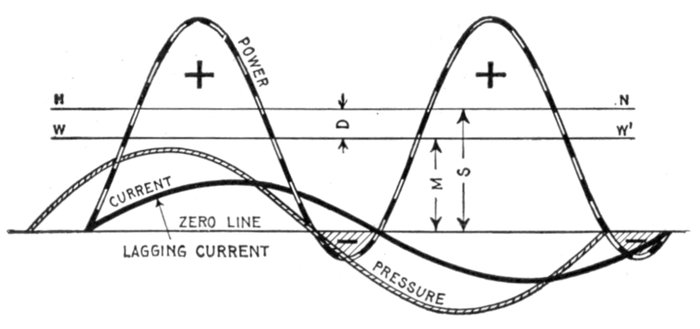

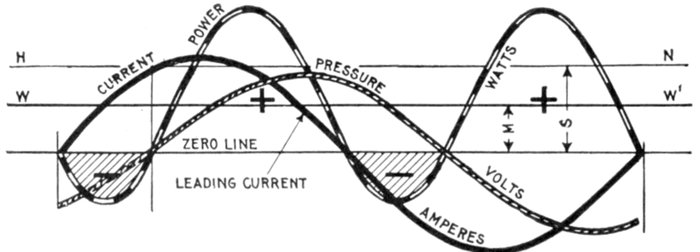

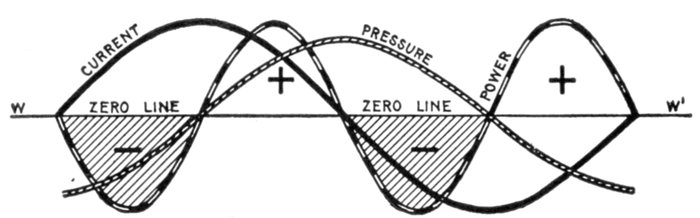

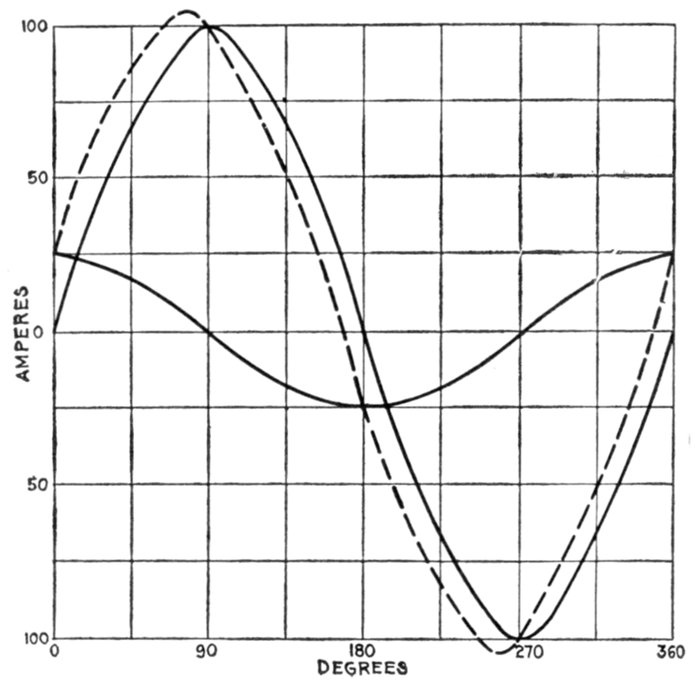

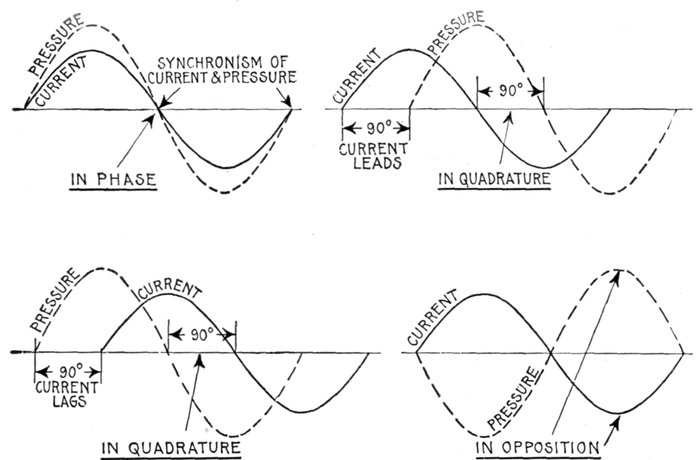

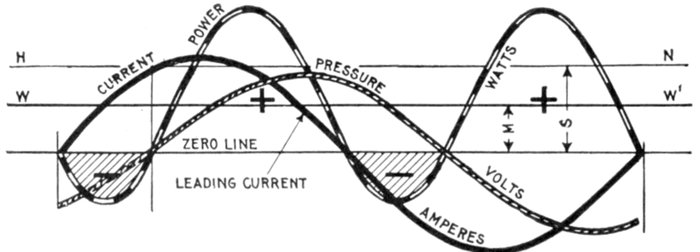

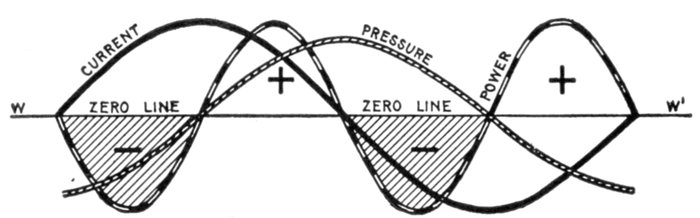

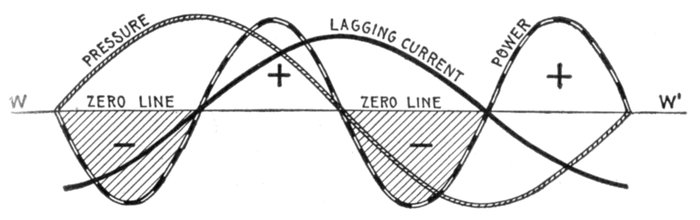

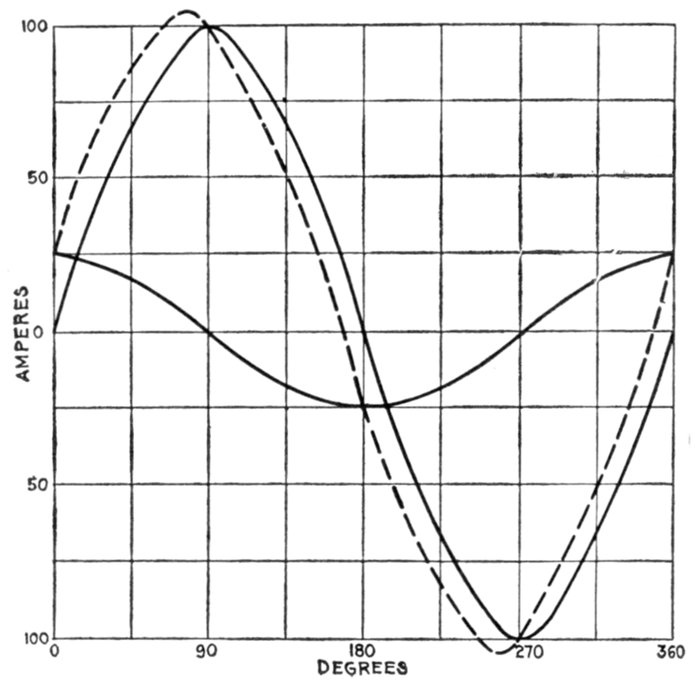

Figs. 1,230 to 1,233.—Curves showing some phase relations between current and pressure. Fig. 1,230, synchronism of current

and pressure, expressed by the term "in phase," meaning simultaneous zero values, and simultaneous maximum values of the

same sign; fig. 1,231, in quadrature, current leading 90°; fig. 1,232 in quadrature, current lagging 90°; fig. 1,233, in opposition,

meaning that the phase different between current and pressure is 180°.

[Pg 1010]

Maximum Volts and Amperes.—In the operation of an

alternator, the pressure and strength of the current are continually

rising, falling and reversing. During each cycle there

are two points at which the pressure or current reaches its

greatest value, being known as the maximum value. This

maximum value is not used to any great extent, but it shows the

maximum to which the pressure rises, and hence, the greatest

strain to which the insulation of the alternator is subjected.

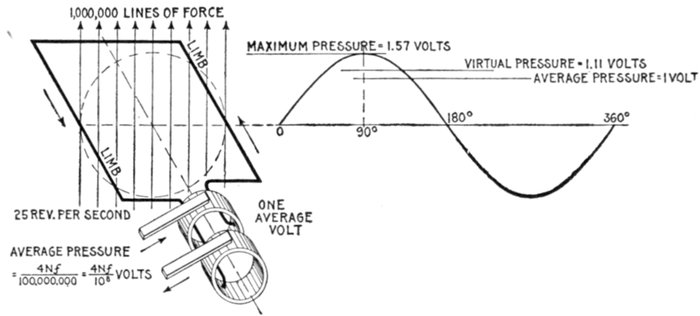

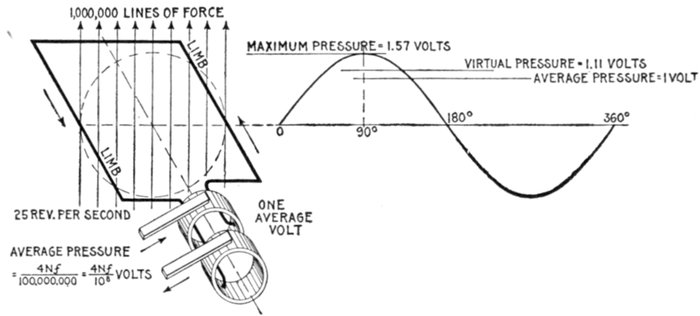

Fig. 1,234.—Elementary alternator developing one average volt. If the loop make one revolution

per second, and the maximum number of lines of force embraced by the loop in the

position shown (the zero position) be denoted by N, then each limb will cut 2N lines per

second, because it cuts every line during the right sweep and again during the left

sweep. Hence each limb develops an average pressure of 2N units (C.G.S. units),

and as both limbs are connected in series, the total pressure is 4N units per revolution.

Now, if the loop make f revolutions per second instead of only one, then f times as many

lines will be cut per second, and the average pressure will be 4N f units. Since the C.G.S.

unit of pressure is so extremely small, a much greater practical unit called the volt is used,

which is equal to 100,000,000, or 108 C.G.S. units is employed. Hence average voltage =

4Nf ÷ 108. The value of N in actual machines is very high, being several million lines

of force. The illustration shows one set of conditions necessary to generate one average

volt. The maximum pressure developed is 1 ÷ .637 = 1.57 volts; virtual pressure =

1.57 × .707 = 1.11 volts.

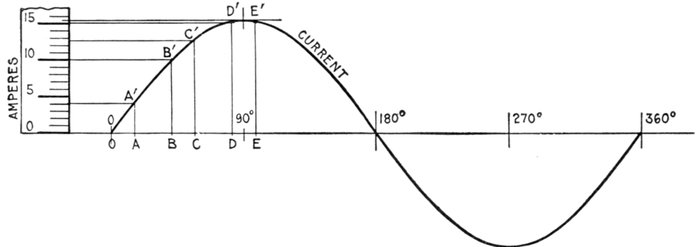

Average Volts and Amperes.—Since the sine curve is used

to represent the alternating current, the average value may be

defined as: the average of all the ordinates of the curve for one-half

of a cycle.

[Pg 1011]

Ques. Of what use is the average value?

Ans. It is used in some calculations but, like the maximum

value, not very often. The relation between the average and

virtual value is of importance as it gives the form factor.

Virtual Volts and Amperes.—The virtual[1] value of an

alternating pressure or current is equivalent to that of a direct

pressure or current which would produce the same effect; those

effects of the pressure and current are taken which are not

affected by rapid changes in direction and strength,—in the

case of pressure, the reading of an electrostatic voltmeter, and

in the case of current, the heating effect.

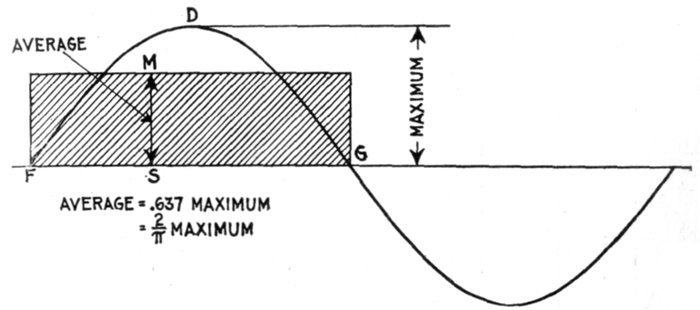

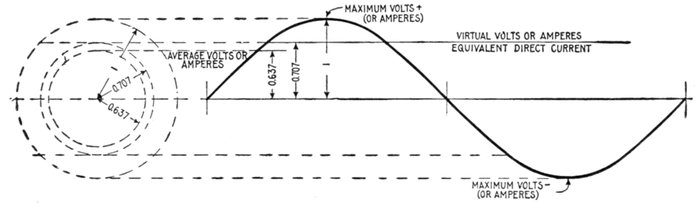

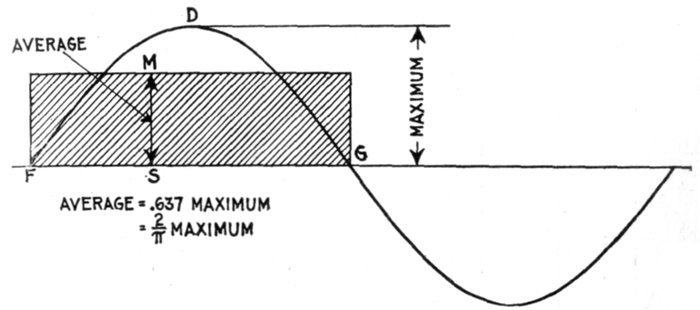

Fig. 1,235.—Maximum and average values of the sine curve. The average value of the sine

curve is represented by an ordinate MS of such length that when multiplied by the base

line FG, will give a rectangle MFSG whose area is equal to that included between the curve

and base line FDGS.

[Pg 1012]

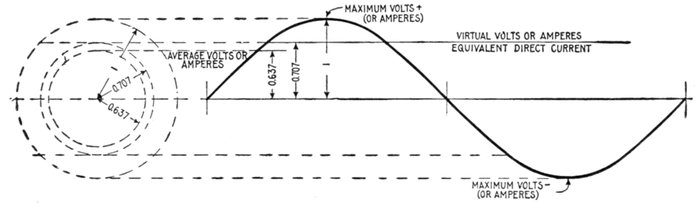

Fig. 1,236.—Diagram illustrating "virtual" volts and amperes. The word virtual is defined as: Being in essence or effect, not in

fact; not actual, but equivalent, so far as effect is concerned. As applied to the alternating current, it denotes an imaginary direct

current of such value as will produce an effect equivalent to that of the alternating current. Thus, a virtual pressure of 1,000

volts is one that would produce the same deflection in an electrostatic voltmeter as a direct pressure of 1,000 volts: a virtual

current of 10 amperes is that current which would produce the same heating effect as a direct current of 10 amperes. Both

pressure and current vary continually above and below the virtual values in alternating current circuits. Distinction should

be made between the virtual and "effective" values of an alternating current. See fig. 1,237. The word effective is commonly

used erroneously for virtual. See note page 1,011.

The attraction (or repulsion)

in electrostatic

voltmeters is proportional

to the square of the volts.

The readings which

these instruments give, if

first calibrated by using

steady currents, are not

true means, but are the

square roots of the means of

the squares.

Now the mean of the

squares of the sine (taken

over either one quadrant or

a whole circle) is ½; hence

the square root of mean

square value of the sine

functions is obtained by

multiplying their maximum

value by 1 ÷ √2, or by

0.707.

The arithmetical mean

of the values of the sine,

however, is 0.637. Hence

an alternating current, if it

obey the sine law, will produce

a heating effect greater

than that of a steady current

of the same average

strength, by the ratio of

0.707 to 0.637; that is,

about 1.11 times greater.

If a Cardew voltmeter

be placed on an alternating

circuit in which the volts

are oscillating between

maxima of +100 and -100

volts, it will read 70.7 volts,

though the arithmetical

mean is really only 63.7;

and 70.7 steady volts would

be required to produce an

equal reading.

[Pg 1013]

Fig. 1,237.—Diagram illustrating virtual and effective pressure. If the coil be short circuited

by the switch and a constant virtual pressure be impressed on the circuit, the whole of

the impressed pressure will be effective in causing current to flow around the circuit.

In this case the virtual and effective pressures will be equal. If the coil be switched into

circuit, the reverse pressure due to self induction will oppose the virtual pressure; hence, the

effective pressure (which is the difference between the virtual and reverse pressures) will

be reduced, the virtual or impressed pressure remaining constant all the time. A virtual

current is that indicated by an ammeter regardless of the phase relation between current and

pressure. An effective current is that indicated by an ammeter when the current is in phase

with the pressure. In practice, the current is hardly ever in phase with the pressure, usually

lagging, though sometimes leading in phase. Now the greater this phase difference, either

way, the less is the power of a given virtual current to do work. With respect to this

feature, effective current may be defined as: that proportion of a given virtual current which

can do useful work. If there be no phase difference, then effective current is equal to

virtual current.

The matter may be looked at in a different way. If an alternating

current is to produce in a given wire the same amount of effect as a

continuous current of 100 amperes, since the alternating current goes

down to zero twice in each period, it is clear that it must at some point

in the period rise to a maximum greater than 100 amperes. How much

greater must the maximum be? The answer is that, if it undulate

up and down with a pure wave form, its maximum must be √2 times

as great as the virtual mean; or conversely the virtual amperes will

be equal to the maximum divided by √2. In fact, to produce equal

effect, the equivalent direct current will be a kind of mean between the

maximum and the zero value of the alternating current; but it must

not be the arithmetical mean, nor the geometrical mean, nor the harmonic

mean, but the quadratic mean; that is, it will be the square root

of the mean of the squares of all the instantaneous values between zero

and maximum.

Effective Volts and Amperes.—Virtual pressure, although

already explained, may be further defined as the pressure

impressed on a circuit. Now, in nearly all circuits the impressed[Pg 1014]

or virtual pressure meets with an opposing pressure due to

inductance and hence the effective pressure is something less

than the virtual, being defined as that pressure which is

available for driving electricity around the circuit, or for doing

work. The difference between virtual and effective pressure is

illustrated in fig. 1,237.

Ques. Does a given alternating voltage affect the

insulation of the circuit differently than a direct pressure

of the same value?

Ans. It puts more strain on the insulation in the same

proportion as the maximum pressure exceeds the virtual pressure.

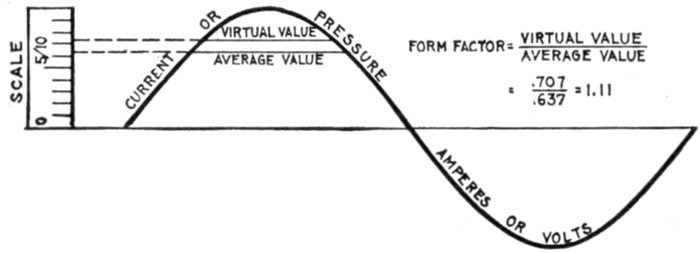

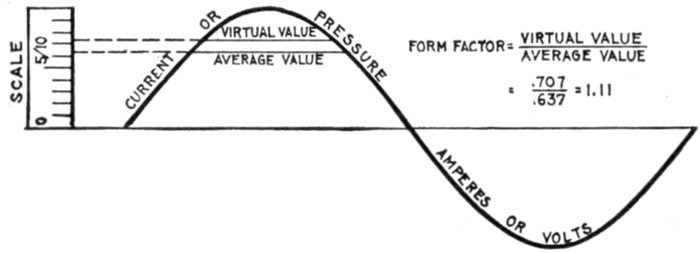

Fig. 1,238.—Current or pressure curve illustrating form factor. It is simply the virtual value

divided by the average value. For a sine wave the virtual value is 1 / √2 times the maximum, and

the average is 2 / π times the maximum, so that the form factor is π/2√2 or 1.11. The induction

wave which generates an alternating pressure wave has a maximum value proportional to

the area, that is, to the average value of the pressure wave. Hence the induction values

corresponding to two pressure waves whose virtual values are equal, will be inversely

proportional to their form factors. This is illustrated by the fact that a peaked wave

causes less hysteresis loss in a transformer core than a flat topped wave, owing to the

higher form factor of the peaked wave. See wave forms, figs. 1,245 to 1,248.

Form Factor.—This term was introduced by Fleming, and

denotes the ratio of the virtual value of an alternating wave to

the average value. That is

Ques. What does this indicate?

Ans. It gives the relative heating effects of alternating and

direct currents, as illustrated in figs. 1,239 and 1,240.

That is, the alternating current will have about 11 per cent. more heating

power than the direct current which is of the same average strength.

If an alternating current voltmeter be placed upon a circuit in which

the volts range from +100 to -100, it will read 70.7 volts, although

the arithmetical average, irrespective of + or-sign, is only 63.7 volts.

If the voltmeter be connected to a direct current circuit, the pressure

necessary to give the same reading would be 70.7 volts.

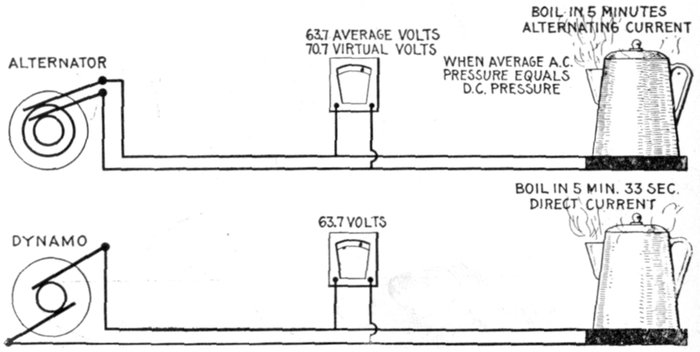

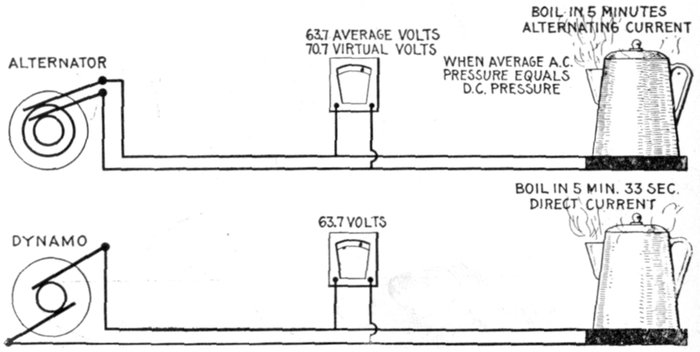

Figs. 1,239 and 1,240.—Relative heating effects of alternating and direct currents. If it takes

say five minutes to produce a certain heating effect with alternating current at say 63.7

average volts, it will take 33 seconds longer with direct current at the same pressure, that

is, the alternating current has about 11 per cent. more heating power than the direct current

of the same average pressure. The reader should be careful not to get a wrong conception

of the above; it does not mean that there is a saving by using alternating current.

When both voltmeters read the same, that is, when the virtual pressure of the alternating

current is the same as the direct current pressure, the heating effect is of course the same.

Ques. What is the relation between the shape of the

wave curve and the form factor?

Ans. The more peaked the wave, the greater the value of

its form factor.

A form factor of units would correspond to a rectangular wave; this

is the least possible value of the form factor, and one which is not

realized in commercial machines.

[Pg 1016]

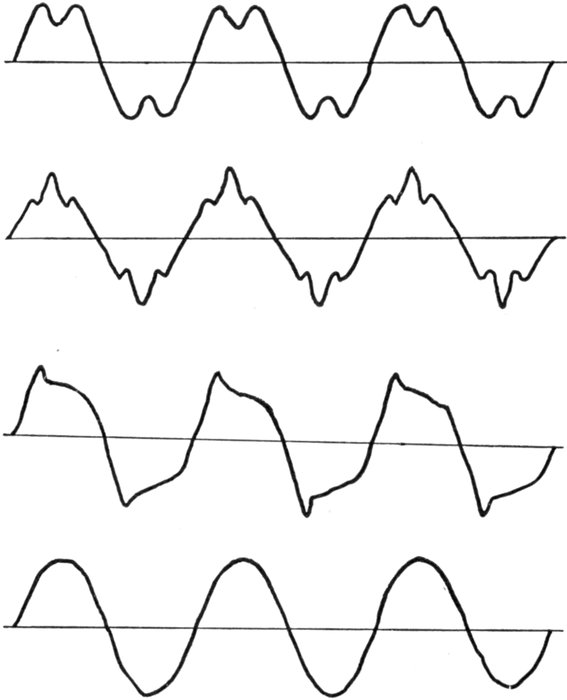

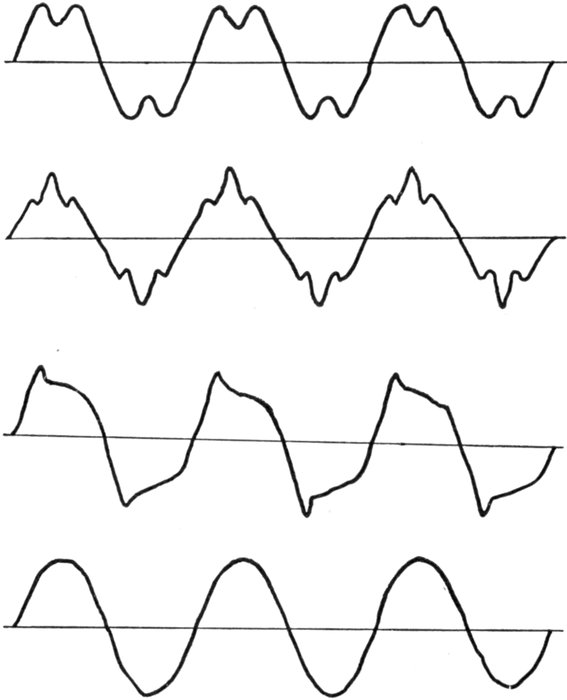

Figs. 1,241 to 1,244.—Various forms of pressure or current waves. Figs. 1,241 to 1,243 show

the general shape of the waves produced by some alternators used largely for lighting

work and having toothed armatures. The effect of the slots and shape of pole pieces is

here very marked. Fig. 1,244 shows a wave characteristic of large alternators designed

for power transmission and having multi-slot or distributed windings.

[Pg 1017]

Wave Form.—There is always more or less irregularity in

the shape of the current waves as met in practice, depending

upon the construction of the alternator.

The ideal wave curve is the so called true sine wave, and is

obtained with a rate of cutting of lines of force, by the armature

coils, equivalent to the swing of a pendulum, which increases

in speed from the end to the middle of the swing, decreasing at

the same rate after passing the center. This swing is expressed

in physics, as "simple harmonic motion".

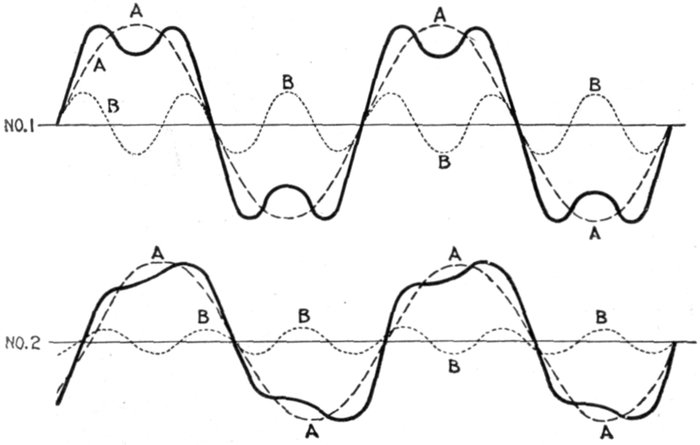

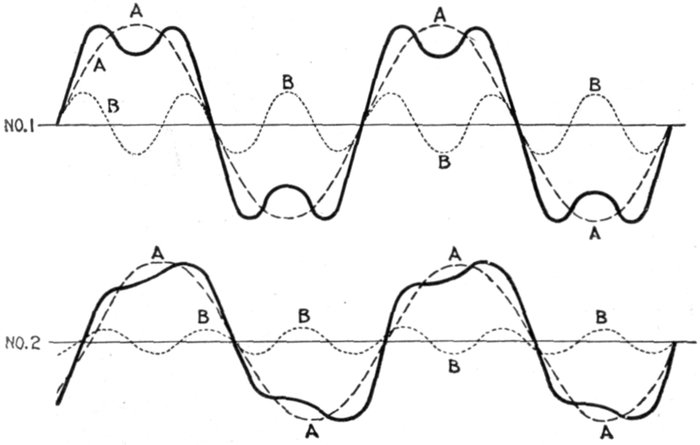

Figs. 1,245 and 1,246.—Resolution of complex curves into sine curves. The heavy curve can

be resolved into the simpler curves A and B shown in No. 1, the component curves A and

B have in the ratio of three to one; that is, curve B has three times as many periods per

second as curve A. All the curves, however, cross the zero line at the same time, and the

resultant curve, though curiously unlike either of them, has a certain symmetry. In No. 2

the component curves, besides having periods in the ratio of three to one, cross the zero

line at different points. The resultant curve produced is still less similar to its components,

and is curiously and unsymmetrically humped. At first sight it is difficult to believe that

such a curious curve could be resolved into two such simple and symmetrical ones. In

both figures the component curves are sine curves, and as the curves for sine and cosine

functions are exactly similar in form, the simplest supposition that can be made for the

variation of pressure or of current is that both follow a sine law.

[Pg 1018]

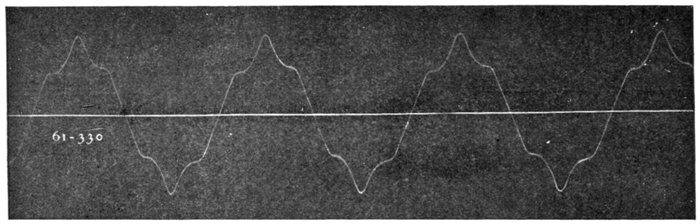

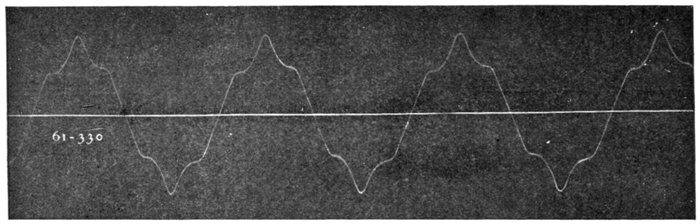

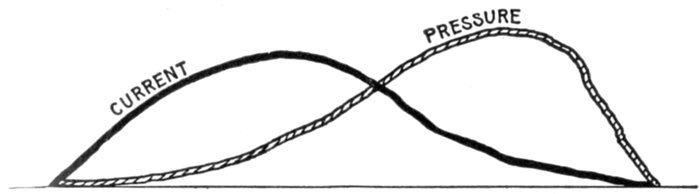

Fig. 1,247.—Reproduction of oscillograph record of wave form of alternator with one coil per phase per pole. Here

the so-called "super-imposed harmonic" is clearly indicated.

Fig. 1,248.—Reproduction of oscillograph record of Wagner alternator having three coils per phase per pole.

[Pg 1019]

The losses in all secondary apparatus are slightly lower with

the so called peaked form of wave. For the same virtual voltage,

however, the top of the peak will be much higher, thereby submitting

the insulation to that much greater strain. By reason

of the fact that the losses are less under such wave forms, many

manufacturers in submitting performance data on transformers

recite that the figures are for sine wave conditions, stating

further that if the transformers are to be operated in a circuit

more peaked than the sine wave, the losses will be less than

shown.

The slight saving in the losses of secondary apparatus, obtained

with a peaked wave, by no means compensates for the increased

insulation strains and an alternator having a true sine wave is

preferred.

Ques. What determines the form of the wave?

Ans. 1. The number of coils per phase per pole, 2, shape of

pole faces, 3, eddy currents in the pole pieces, and 4, the air gap.

Ques. What are the requirements for proper rate of

cutting of the lines of force?

Ans. It is necessary to have, as a minimum, two coils per

phase per pole in three phase work.

Ques. What is the effect of only one coil per phase per

pole?

Ans. The wave form will be distorted as shown in fig. 1,247.

Ques. What is the least number of coils per phase

per pole that should be used for two and three phase

alternators?

Ans. For three phase, two coils, and for two phase, three

coils, per phase per pole.

[Pg 1020]

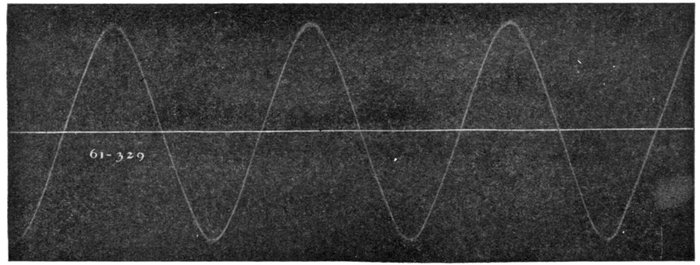

Single or Monophase

Current.—This kind of

alternating current is generated

by an alternator

having a single winding on

its armature. Two wires, a

lead and return, are used

as in direct current.

An elementary diagram

showing the working principles

is illustrated in fig.

1,249, a similar hydraulic

cycle being shown in figs.

1,250 to 1,252.

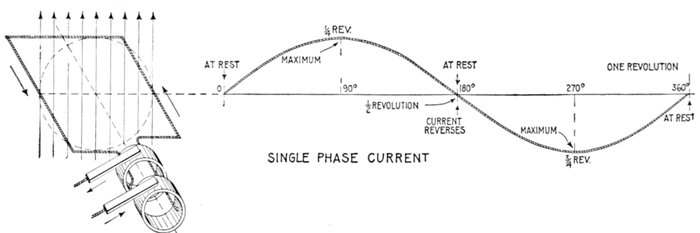

Fig. 1,249.—Elementary one loop alternator and sine curve illustrating single phase alternating current. There are three points

during the revolution at which there is no current: at 0° the position shown, 180°, and 360°; in other words, at the beginning,

middle point and end of the cycle. The current reaches a maximum at 90°, reverses at 180°, and reaches a maximum

in the reverse direction at 270°.

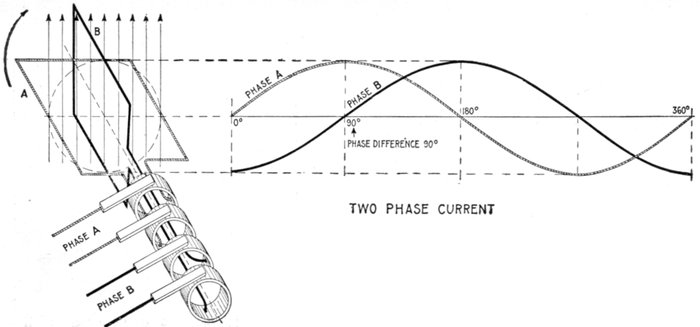

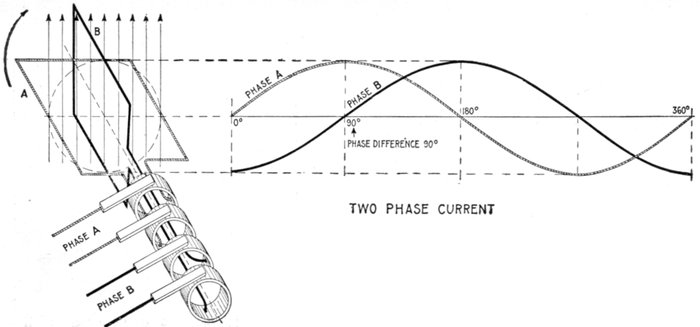

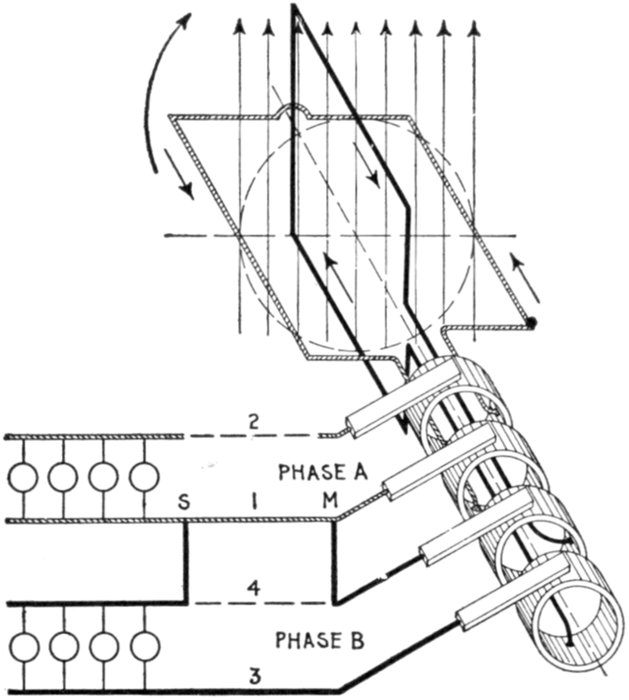

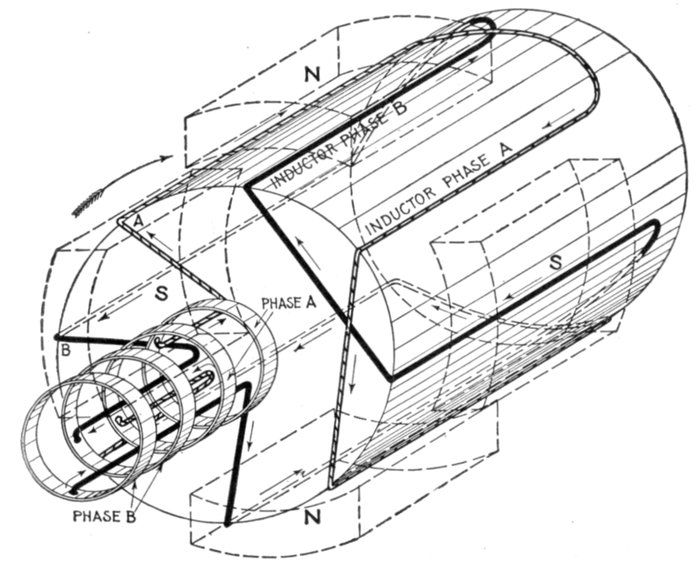

Two Phase Current.—In

most cases two phase

current actually consists of

two distinct single phase

currents flowing in separate

circuits. There is often no

electrical connection between

them; they are of

equal period and equal

amplitude, but differ in

phase by one quarter of a

period. With this phase

relation one of them will

be at a maximum when

the other is at zero. Two

phase current is illustrated[Pg 1021]

by sine curves in fig.

1,253, and by hydraulic

analogy in

figs. 1,254 and 1,255.

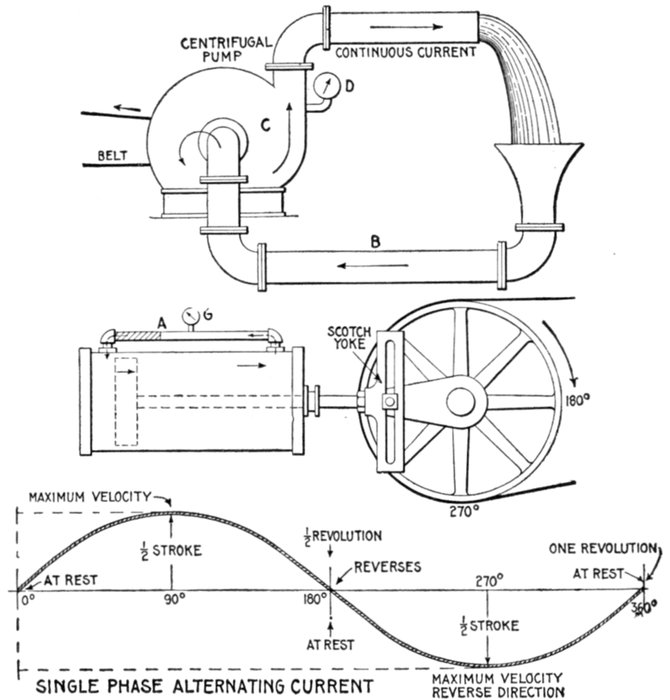

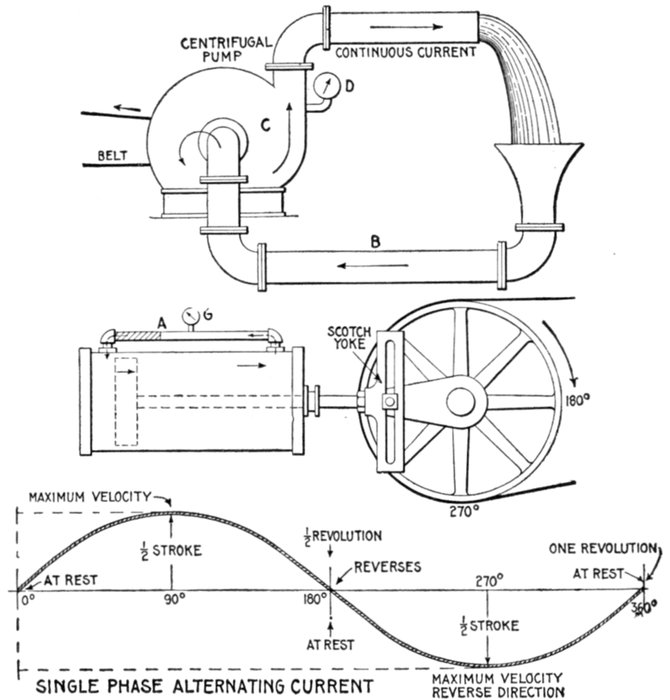

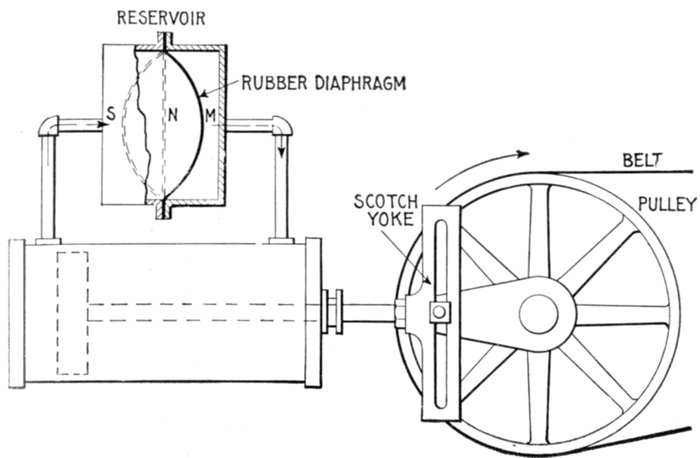

Figs. 1,250 to 1,252.—Hydraulic analogy illustrating the difference between direct (continuous)

and alternating current. In fig. 1,250 a centrifugal pump C forces water to the upper

pipe, from which it falls by gravity to the lower pipe B and re-enters the pump. The

current is continuous, always flowing in one direction, that is, it does not reverse its direction.

Similarly a direct electric current is constant in direction (does not reverse);

though not necessarily constant in value. A direct current, constant in both value and

direction as a result of constant pressure, is called "continuous" current. Similarly in

the figure the flow is constant, and a gauge D placed at any point will register a constant

pressure, hence the current may be called, in the electrical sense, "continuous." The

conditions in fig. 1,251 are quite different. The illustration represents a double acting

cylinder with the ends connected by a pipe A, and the piston driven by crank and Scotch

yoke as shown. In operation, if the cylinder and pipe be full of water, a current of water

will begin to flow through the pipe in the direction indicated as the piston begins its stroke,

increasing to maximum velocity at one-quarter revolution of the crank, decreasing and

coming to rest at one-half revolution, then reversing and reaching maximum velocity

in the reverse direction at three-quarter revolution, and coming to rest again at the end of

the return stroke. A pressure gauge at G will register a pressure which varies with the

current. Since the alternating electric current undergoes similar changes, the sine curve

will apply equally as well to the pump cycle as to the alternating current cycle.

[Pg 1022]

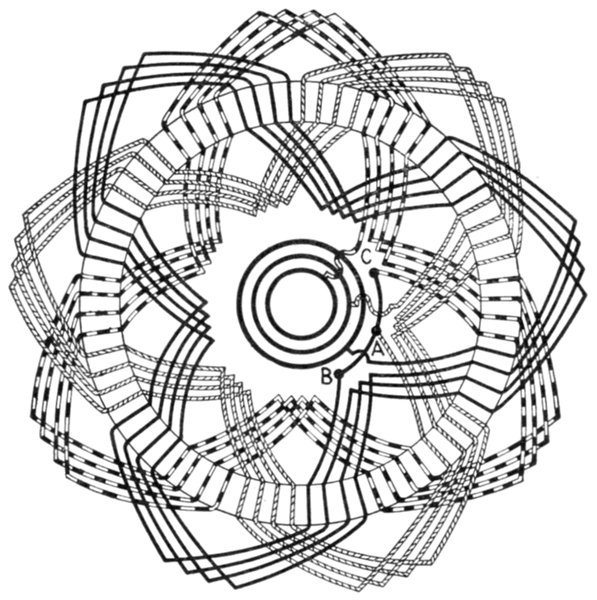

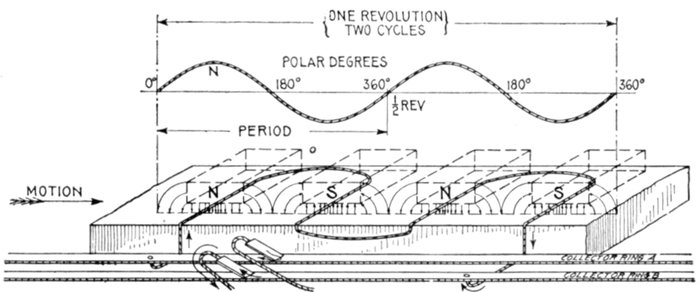

Fig. 1,253.—Elementary two loop alternator and sine curves, illustrating two phase

alternating current. If the loops be placed on the alternator armature at 90 magnetic

degrees, a single phase current will be generated in each of the windings, the

current in one winding being at its maximum value when the other is at zero. In

this case four transmission conductors are generally used, two for each separate

circuit, and the motors to which the current is led have a double winding corresponding

to that on the alternator armature.

If two identical

simple alternators

have their armature

shafts coupled in such

a manner, that when

a given armature coil

on one is directly

under a field pole, the

corresponding coil on

the other is midway

between two poles of

its field, the two currents

generated will

differ in phase by a

half alternation, and

will be two phase

current.

Ques. How must

an alternator be

constructed to

generate two phase

current?

Ans. It must have

two independent

windings, and these

must be so spaced

out that when the

volts generated in

one of the two phases

are at a maximum,

those generated in

the other are at zero.

[Pg 1023]

In other words, the windings, which must be alike, of an equal number

of turns, must be displaced along the armature by an angle corresponding

to one-quarter of a period, that is, to half the pole pitch.

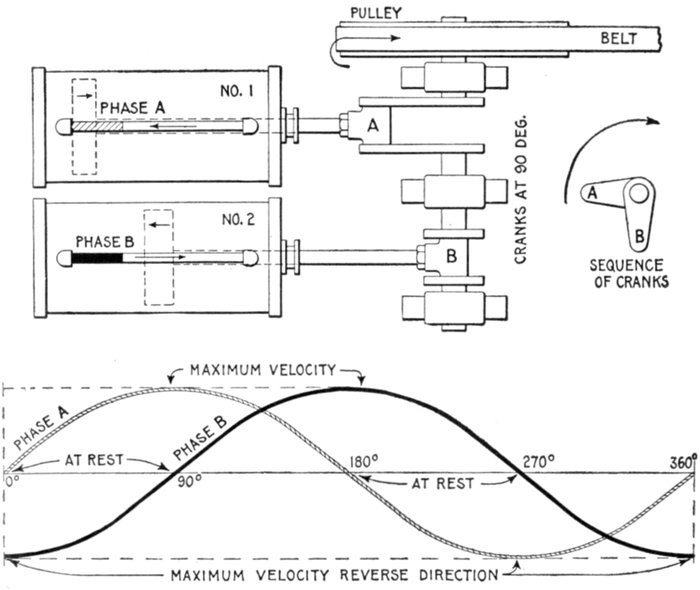

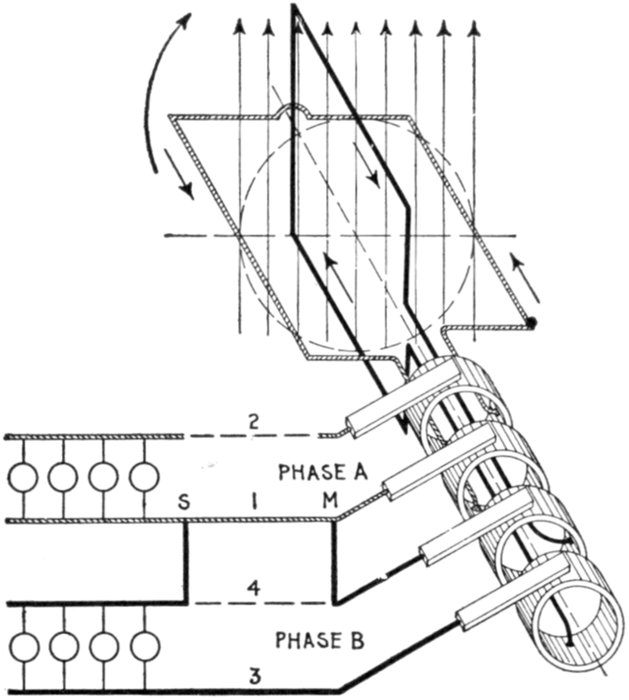

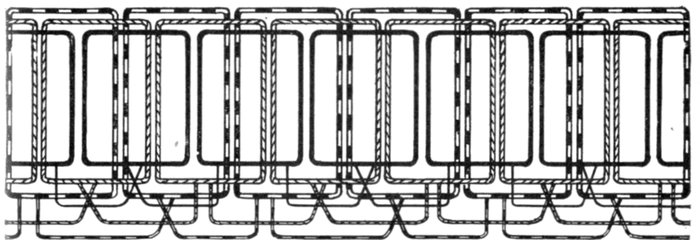

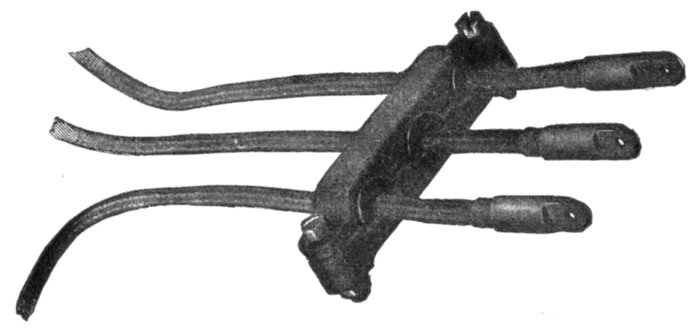

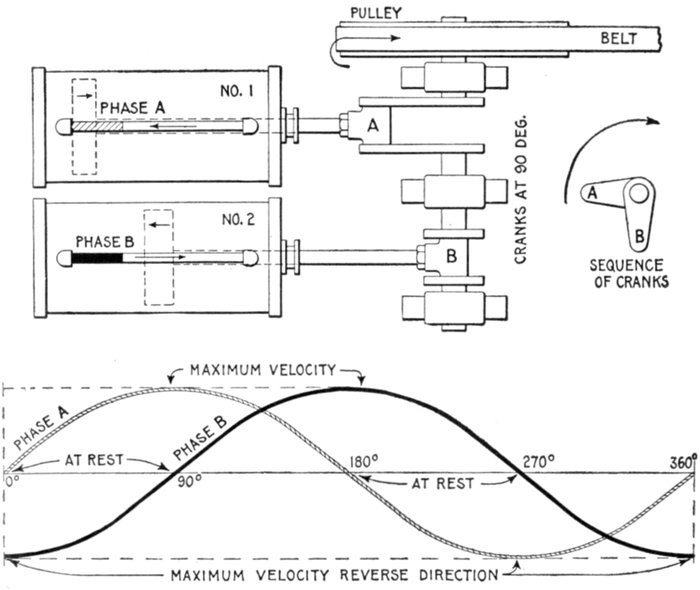

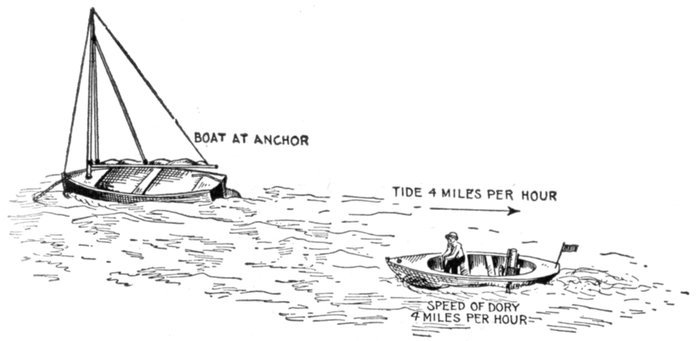

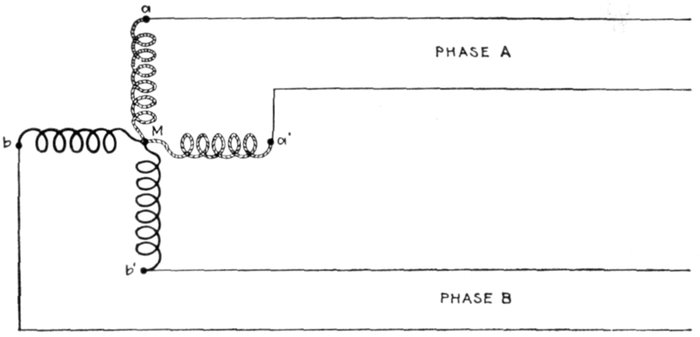

Figs. 1,254 and 1,255.—Hydraulic analogy illustrating two phase alternating current. In the

figure two cylinders, similar to the one in fig. 1,251, are shown, operated from one shaft

by crank and Scotch yoke drive. The cranks are at 90° as shown, and the cylinders and

connecting pipes full of water. In operation, the same cycle of water flow takes place as

in fig. 1,251. Since the cranks are at 90°, the second piston is one-half stroke behind the

first; the flow of water in No. 1 (phase A) is at a maximum when the flow in No. 2 (phase

B) comes to rest, the current conditions in both pipes for the entire cycle being represented

by the two sine curves whose phase difference is 90°. Comparing these curves with fig.

1,253, it will be seen that the water and electric current act in a similar manner.

Figs. 1,254 and 1,255.—Hydraulic analogy illustrating two phase alternating current. In the

figure two cylinders, similar to the one in fig. 1,251, are shown, operated from one shaft

by crank and Scotch yoke drive. The cranks are at 90° as shown, and the cylinders and

connecting pipes full of water. In operation, the same cycle of water flow takes place as

in fig. 1,251. Since the cranks are at 90°, the second piston is one-half stroke behind the

first; the flow of water in No. 1 (phase A) is at a maximum when the flow in No. 2 (phase

B) comes to rest, the current conditions in both pipes for the entire cycle being represented

by the two sine curves whose phase difference is 90°. Comparing these curves with fig.

1,253, it will be seen that the water and electric current act in a similar manner.

The windings of the two phases must, of course, be kept separate,

hence the armature will have four terminals, or if it be a revolving

armature it will have four collector rings.

As must be evident the phase difference may be of any value between

0° and 360°, but in practice it is almost always made 90°.

[Pg 1024]

Ques. In what other way may two phase current be

generated?

Ans. By two single phase alternators coupled to one shaft.

Ques. How many wires are required for two phase

distribution?

Ans. A two phase system requires four lines for its distribution;

two lines for each phase as in fig. 1,253. It is possible, but

not advisable, to reduce the number to 3, by employing one

rather thicker line as a common return for each of the phases

as in fig. 1,256.

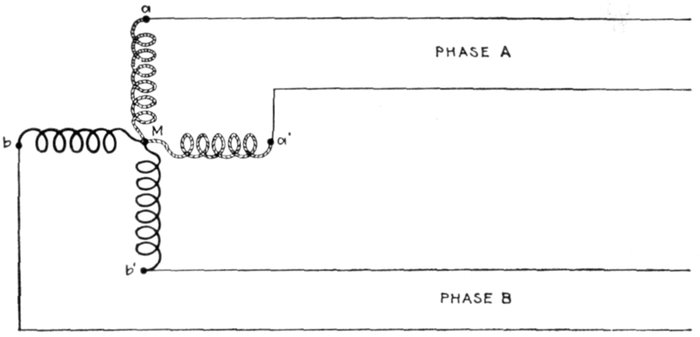

Fig. 1,256.—Diagram of three wire two phase current distribution. In order to save one wire

it is possible to use a common return conductor for both circuits, as shown, the dotted

portion of one wire 4 being eliminated by connecting across to 1 at M and S. For long

lines this is economical, but the interconnection of the circuits increases the chance

of trouble from grounds or short circuits. The current in the conductor will be the resultant

of the two currents, differing by 90° in phase.

[Pg 1025]

If this be done, the voltage between the A line and the B line will be

equal to √2 times the voltage in either phase, and the current in the

line used as common return will be √2 times as great as the current in

either line, assuming the two currents in the two phases to be equal.

Ques. In what other way may two phase current be

distributed?

Ans. The mid point of the windings of the two phases may

be united in the alternator at a common junction.

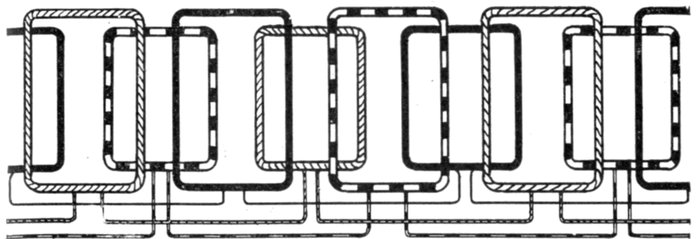

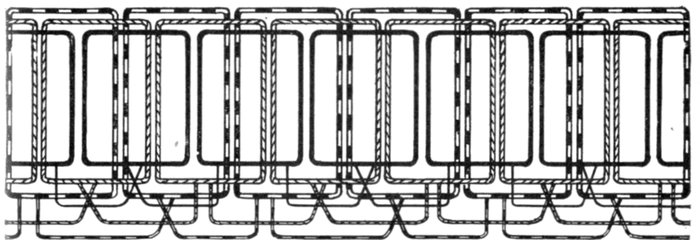

Figs. 1,257 to 1,259.—Various two phase armature connections. Fig. 1,257, two separate

circuit four collector ring arrangement; fig. 1,258, common middle connection, four

collector rings; fig. 1,259, circuit connected in armature for three collector rings. In the

figures the black winding represents phase A, and the light winding, phase B.

This is equivalent to making the machine into a four phase alternator

with half the voltage in each of the four phases, which will then be in

successive quadrature with each other.

Ques. How are two phase alternator armatures wound?

Ans. The two circuits may be separate, each having two

collector rings, as shown in fig. 1,257, or the two circuits may be

coupled at a common middle as in fig. 1,258, or the two circuits

may be coupled in the armature so that only three collector

rings are required as shown in fig. 1,259.

[Pg 1026]

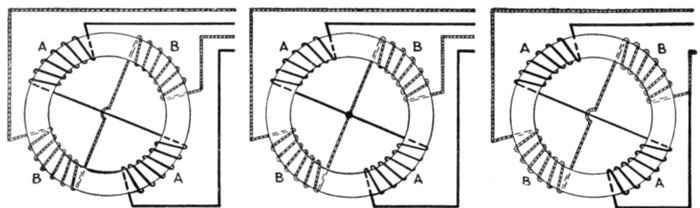

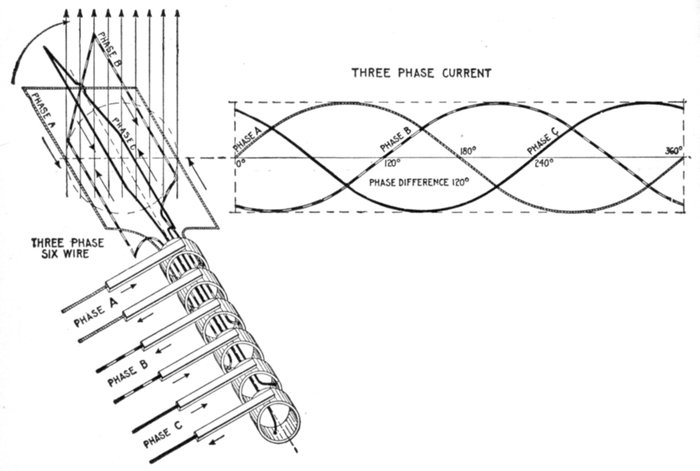

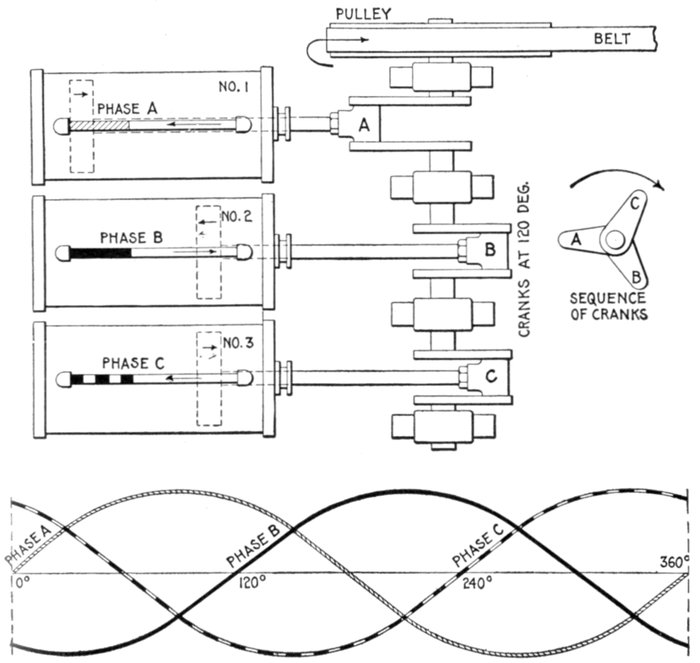

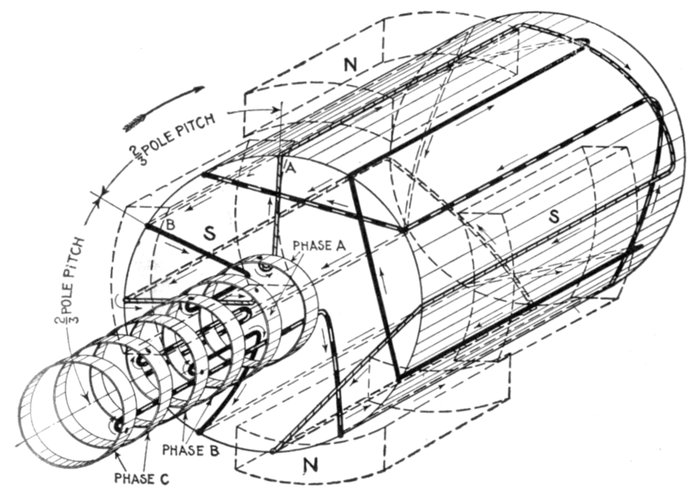

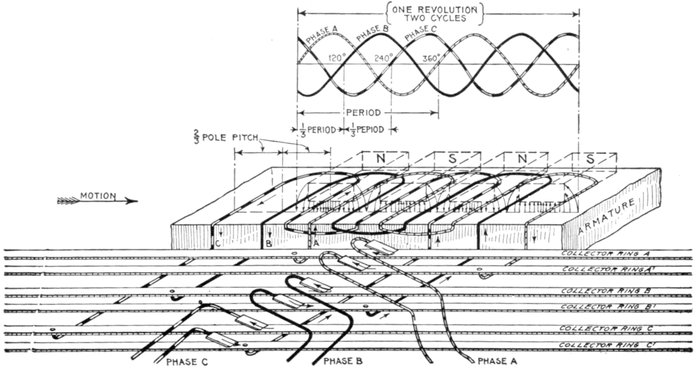

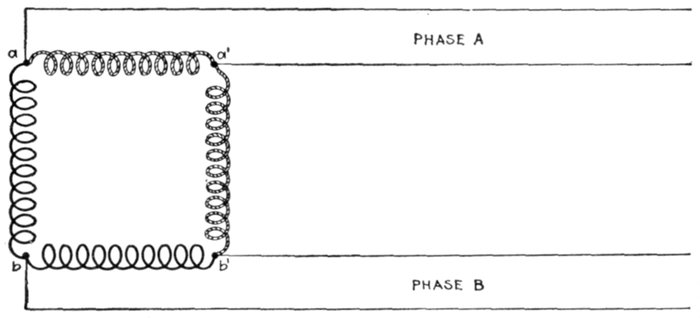

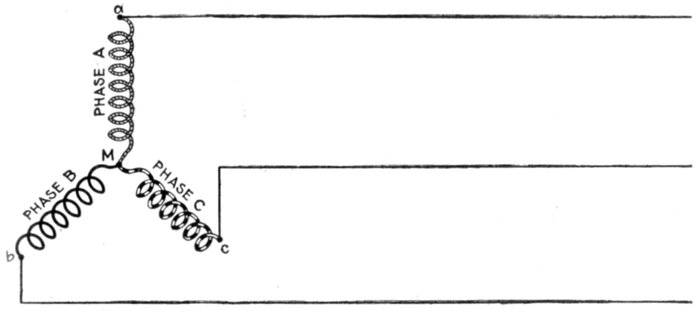

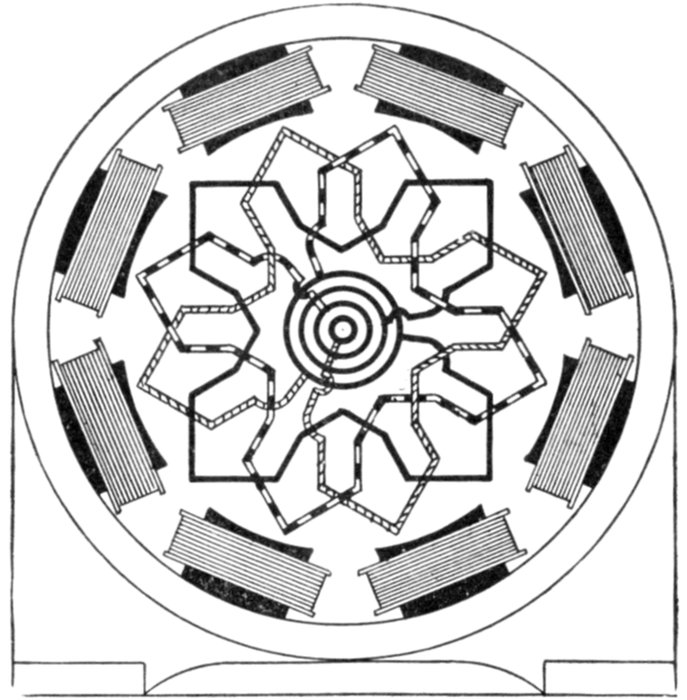

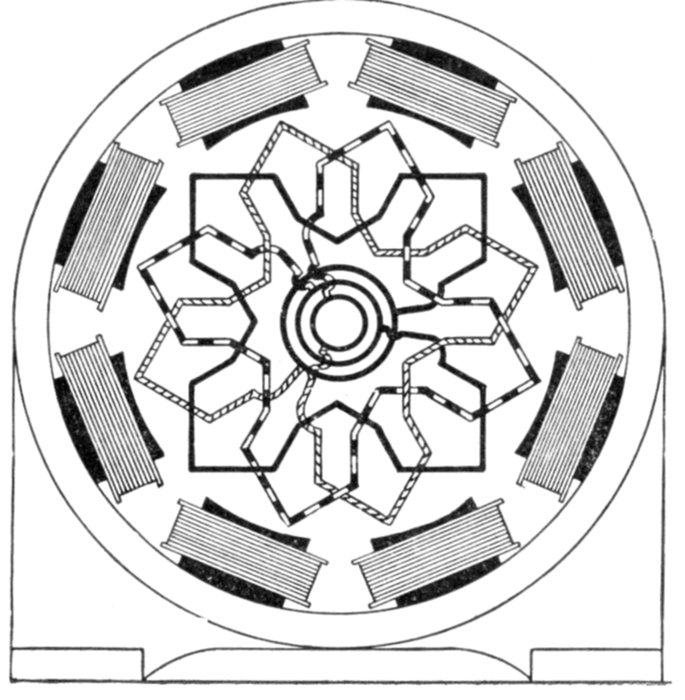

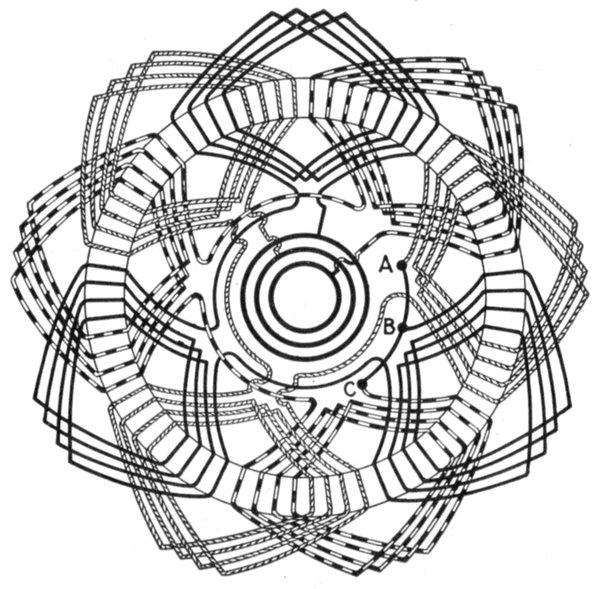

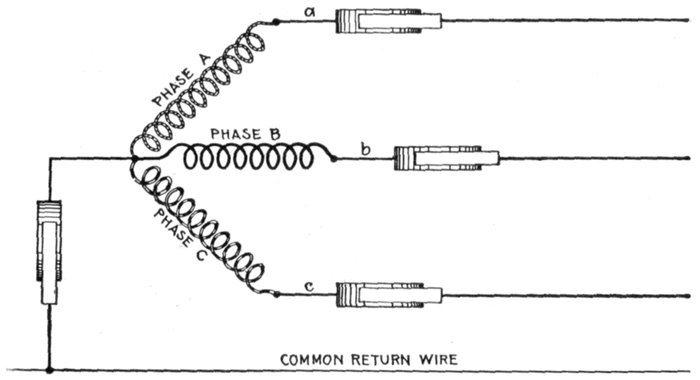

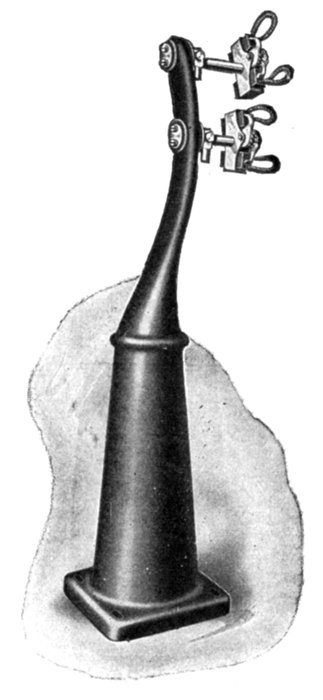

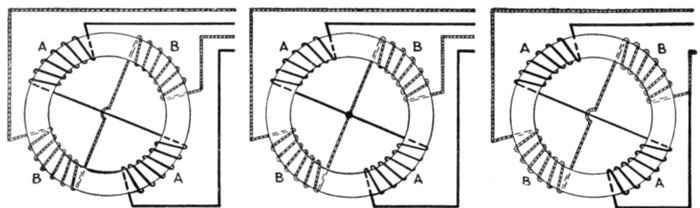

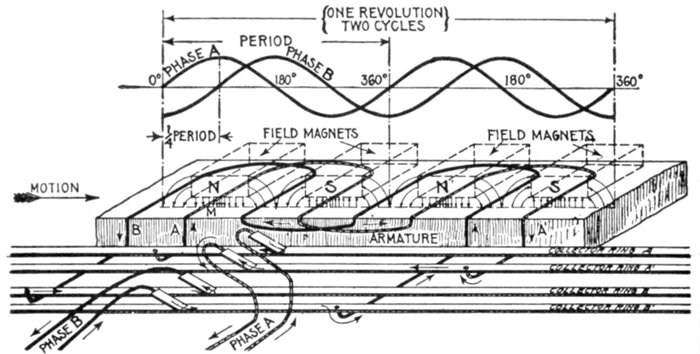

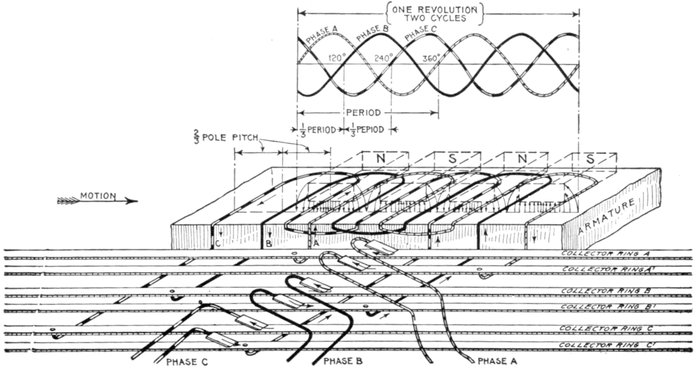

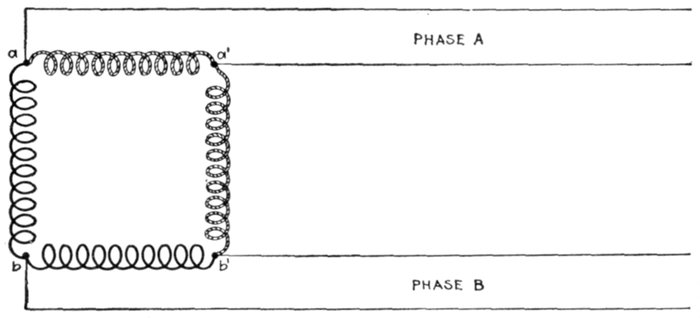

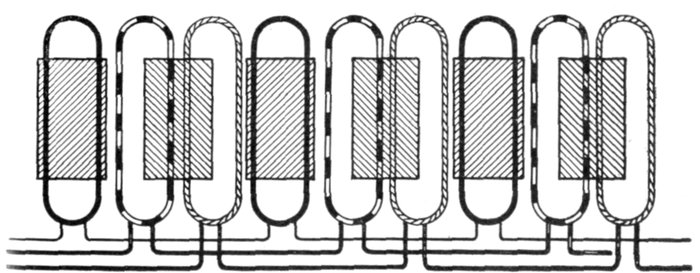

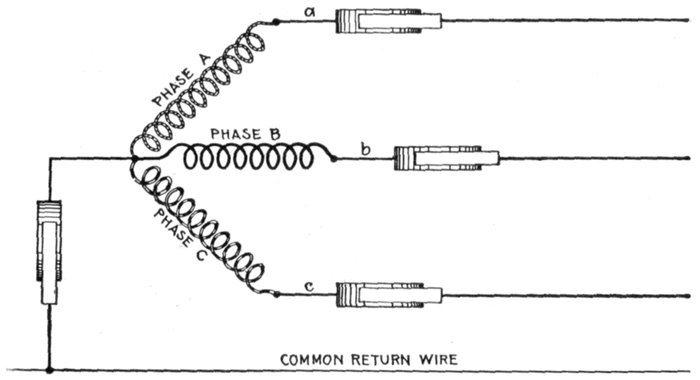

Fig. 1,260.—Elementary three loop alternator and sine curves, illustrating three phase alternating

current. If the loops be placed on the alternator armature at 120 magnetic degrees

from one another, the current in each will attain its maximum at a point one-third of a

cycle distant from the other two. The arrangement here shown gives three independent

single phase currents and requires six wires for their transmission. A better arrangement

and the one generally used is shown in fig. 1,261.

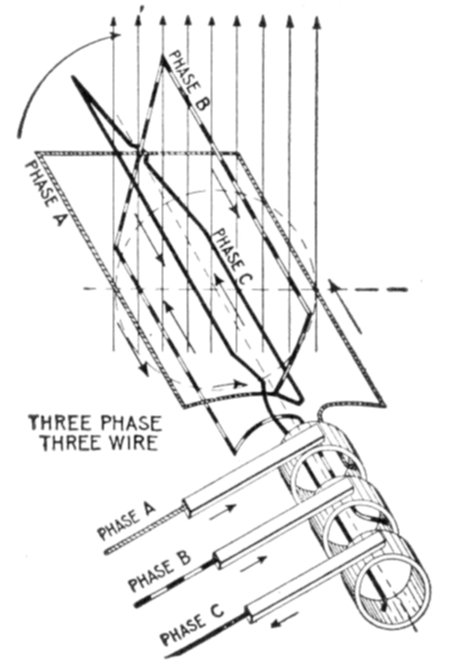

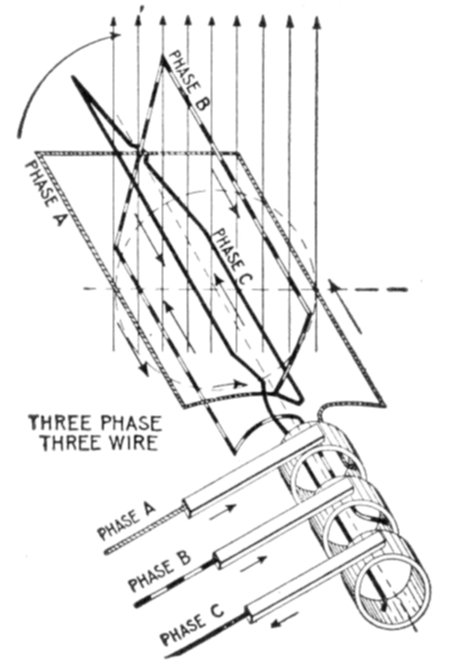

Fig. 1,261.—Elementary three wire three phase alternator. For the transmission of three

phase current, it is not customary to use six wires, as in fig. 1,260, instead, three ends

(one end of each of the loops) are brought together to a common connection as shown,

and the other ends, connected to the collector rings, giving only three wires for the

transmission of the current.

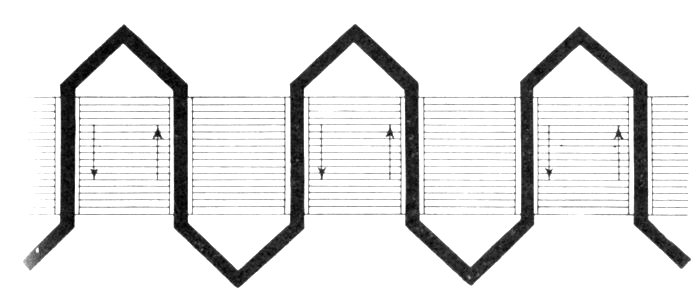

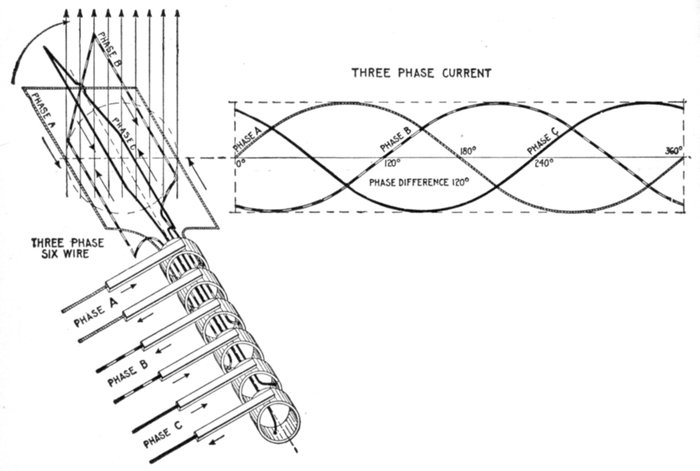

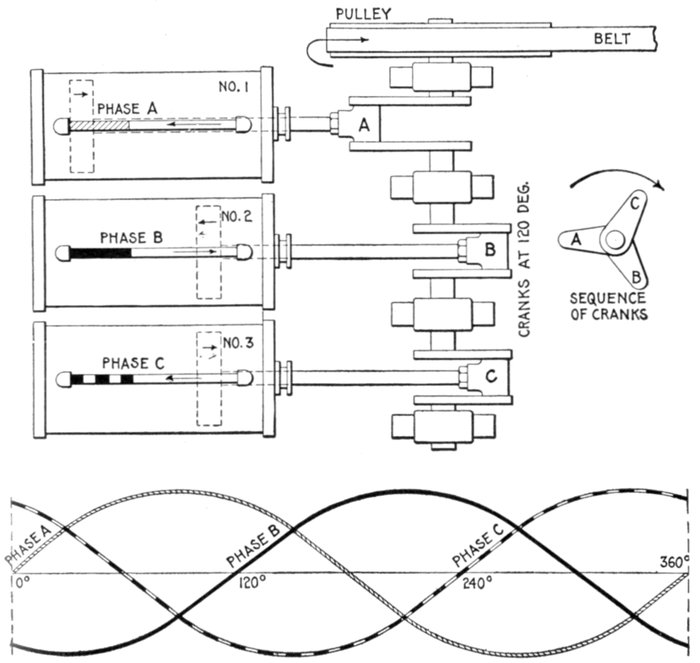

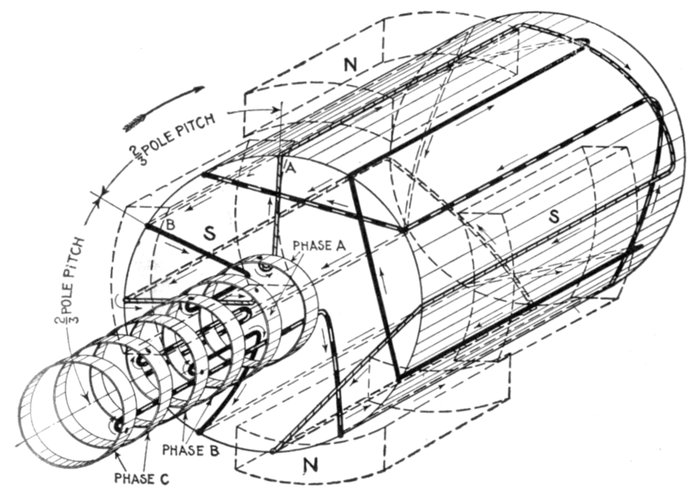

Three Phase Current.—A three phase current consists of

three alternating currents of equal frequency and amplitude,

but differing in phase from each other by one-third of a period.

Three phase current as represented by sine curves is shown in

fig. 1,260, and by hydraulic analogy in fig. 1,262. Inspection of the[Pg 1027]

figures will show that when any one of the currents is at its

maximum, the other two are of half their maximum value,

and are flowing in the opposite direction.

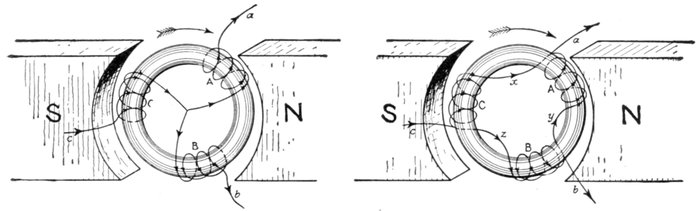

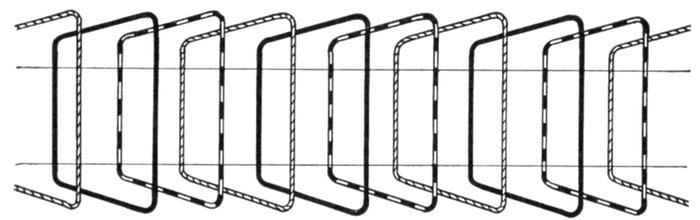

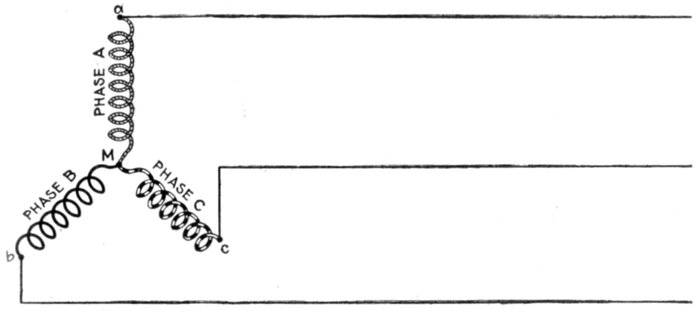

Figs. 1,262 and 1,263.—Hydraulic analogy illustrating three phase alternating current. Three

cylinders are here shown with pistons connected through Scotch yokes to cranks placed

120° apart. The same action takes place in each cylinder as in the preceding cases, the

only difference being the additional cylinder, and difference in phase relation.

Ques. How is three phase current generated?

Ans. It requires three equal windings on the alternator

armature, and they must be spaced out over its surface so as[Pg 1028]

to be successively ⅓ and ⅔ of the period (that is, of the double

pole pitch) apart from one another.

Ques. How many wires are used for three phase

distribution?

Ans. Either six wires or three wires.

Six wires, as in fig. 1,260, might be used where it is desired to supply

entirely independent circuits, or as is more usual only three wires are

used as shown in fig. 1,261. In this case it should be observed that if the

voltage generated in each one of the three phases separately E (virtual)

volts, the voltage generated between any two of the terminals will be

equal to √3 × E. Thus, if each of the three phases generate 100

volts, the voltage from the terminal of the A phase to that of the B

phase will be 173 volts.

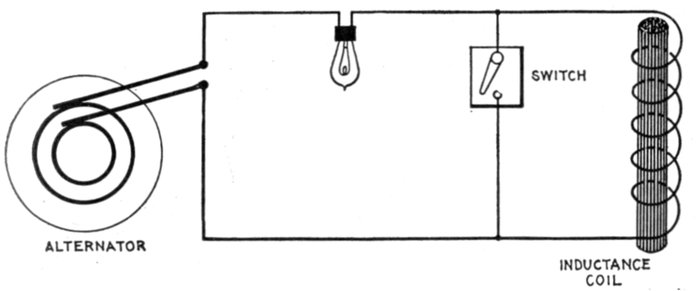

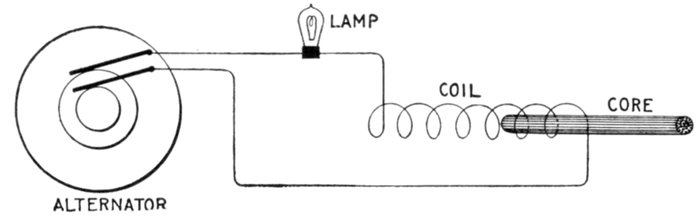

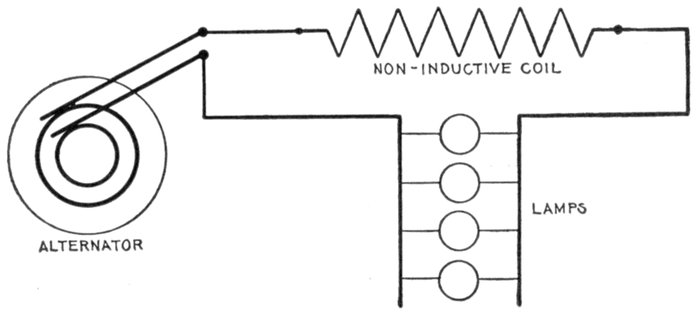

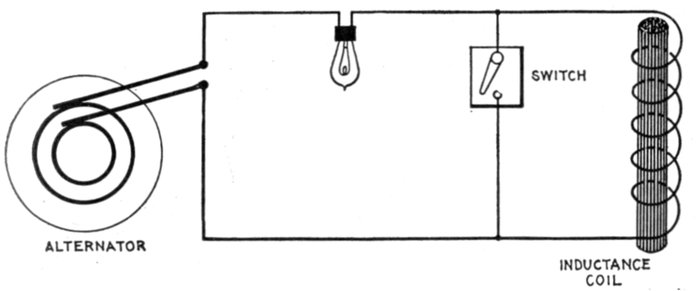

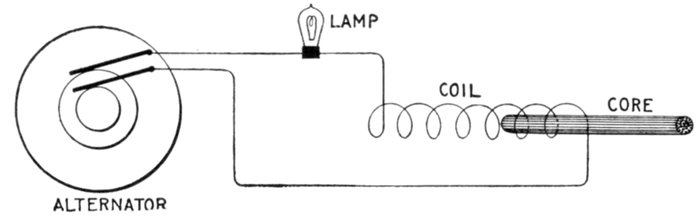

Fig. 1,264.—Experiment illustrating self-induction in an alternating current circuit. If an

incandescent lamp be connected in series with a coil made of one pound of No. 20 magnet

wire, and connected to the circuit, the current through the lamp will be decreased due to

the self-induction of the coil. If now an iron core be gradually pushed into the coil,

the self-induction will be greatly increased and the lamp will go out, thus showing the great

importance which self-induction plays in alternating current work.

Inductance.—Each time a direct current is started, stopped

or varied in strength, the magnetism changes, and induces or

tends to induce a pressure in the wire which always has a direction

opposing the pressure which originally produced the current.

This self-induced pressure tends to weaken the main current at

the start and prolong it when the circuit is opened.

The expression inductance is frequently used in the same sense as

coefficient of self-induction, which is a quantity pertaining to an electric[Pg 1029]

circuit depending on its geometrical form and the nature of the surrounding

medium.

If the direct current maintains the same strength and flow

steadily, there will be no variations in the magnetic field surrounding

the wire and no self-induction, consequently the only retarding

effect of the current will be the "ohmic resistance" of the wire.

If an alternating current be sent through a circuit, there will

be two retarding effects:

1. The ohmic resistance;

2. The spurious resistance.

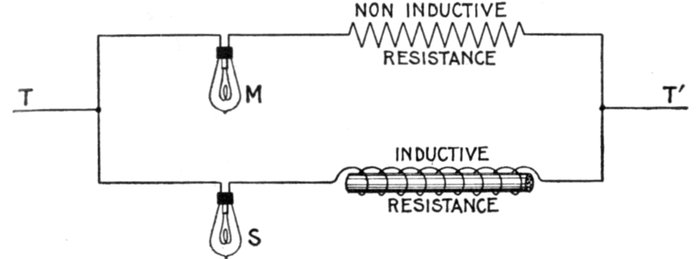

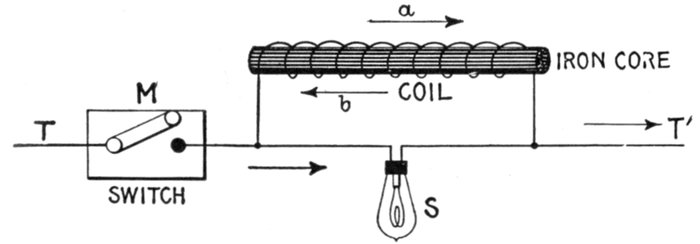

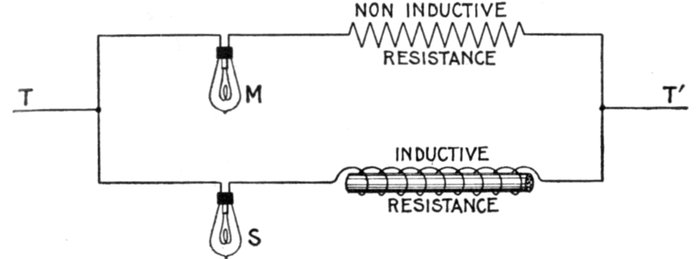

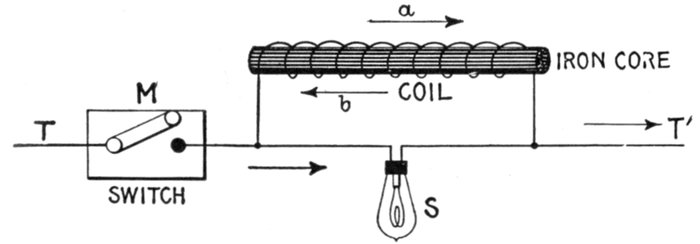

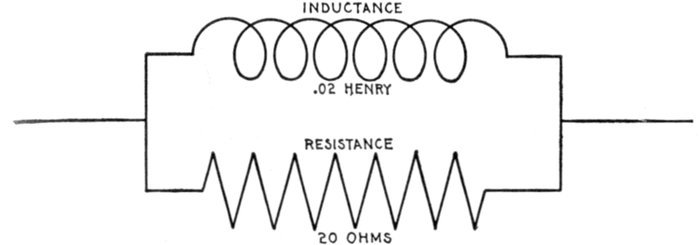

Fig. 1,265.—Non-inductive and inductive resistances. Two currents are shown joined in

parallel, one containing a lamp and non-inductive resistance, and the other a lamp and

inductive resistance. The two resistances being the same, a sufficient direct pressure

applied at T, T' will cause the lamps to light up equally. If, however, an alternating

pressure be applied, M will burn brightly, while S will give very little or no light because

of the effect of the inductance of the inductive resistance.

Ques. Upon what does the ohmic resistance depend?

Ans. Upon the length, cross sectional area and material of

the wire.

Ques. Upon what does the spurious resistance depend?

Ans. Upon the frequency of the alternating current, the

shape of the conductor, and nature of the surrounding medium.

[Pg 1030]

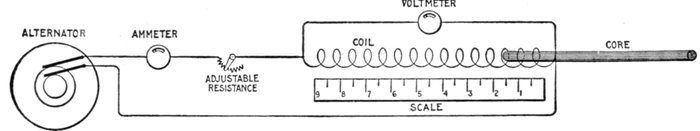

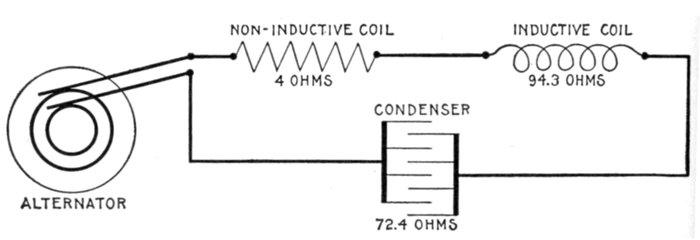

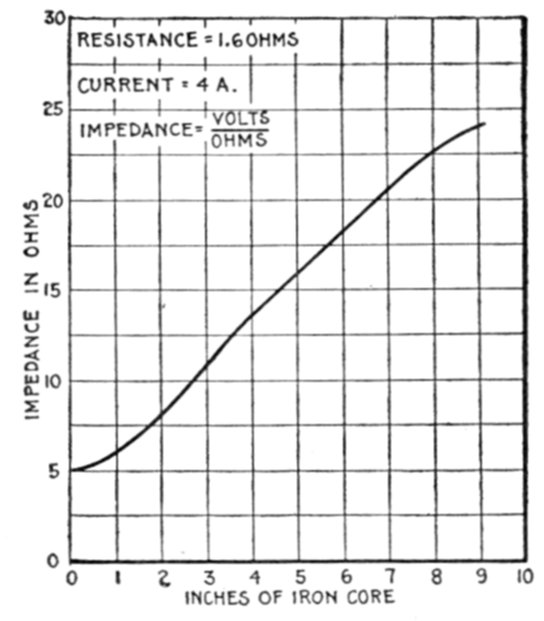

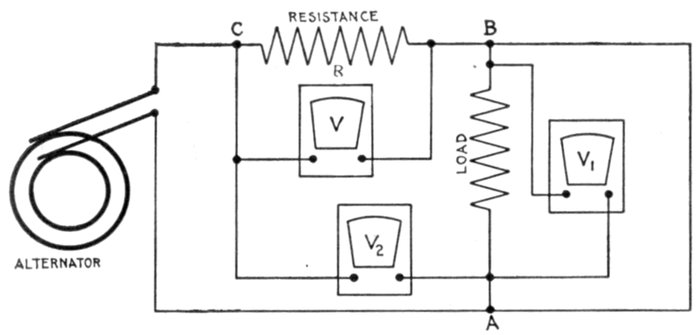

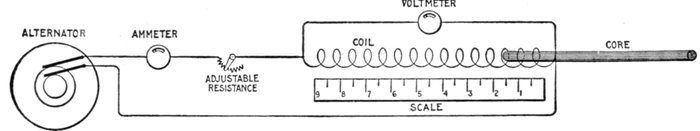

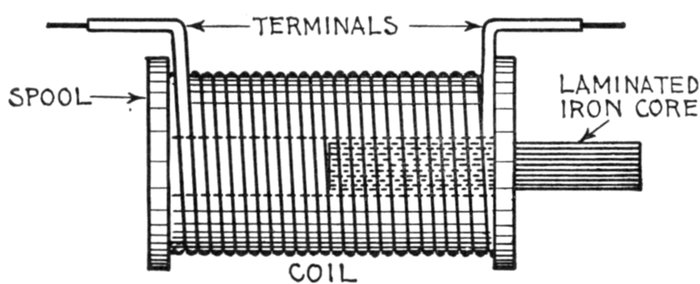

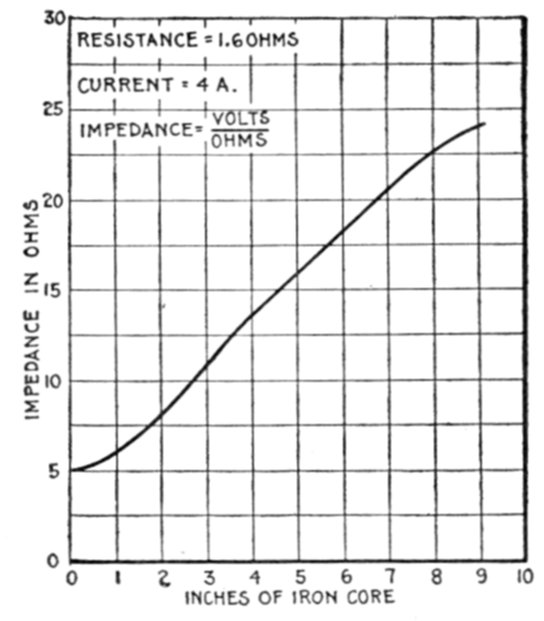

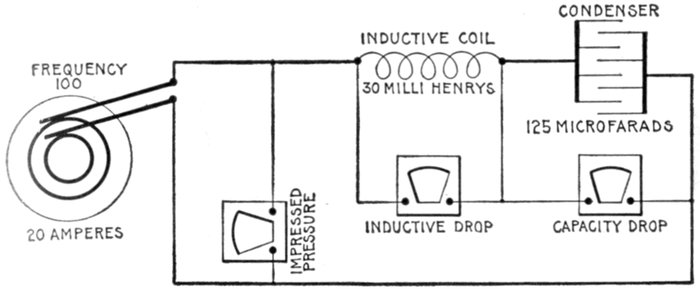

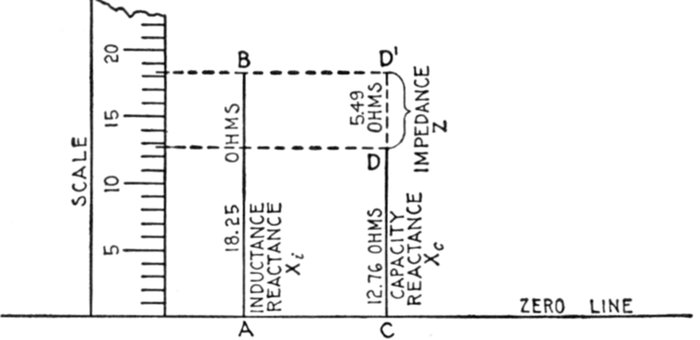

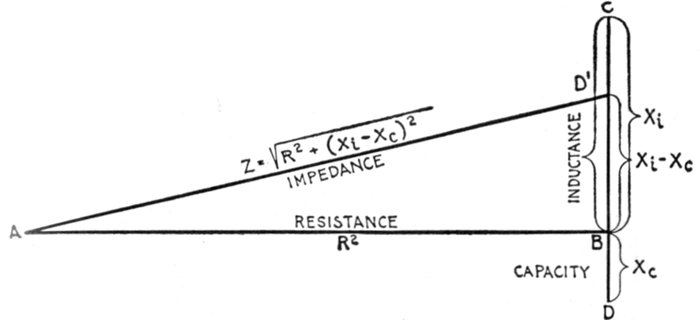

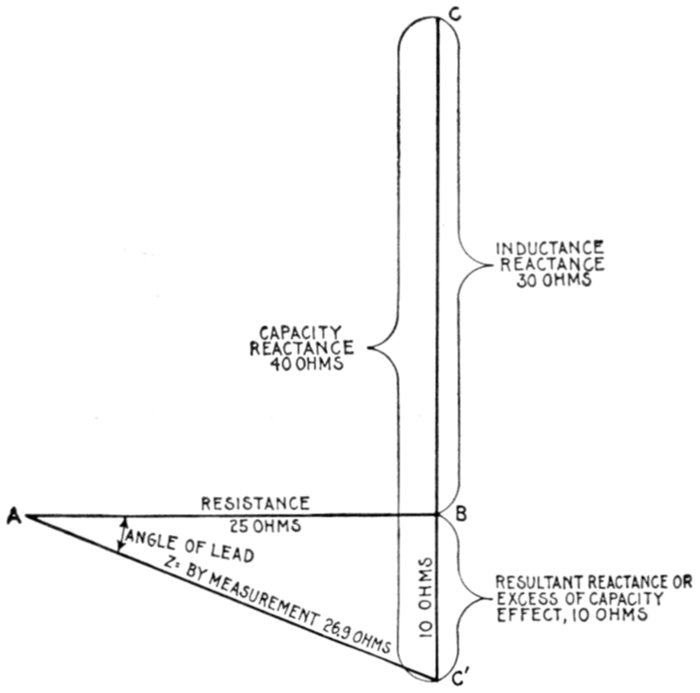

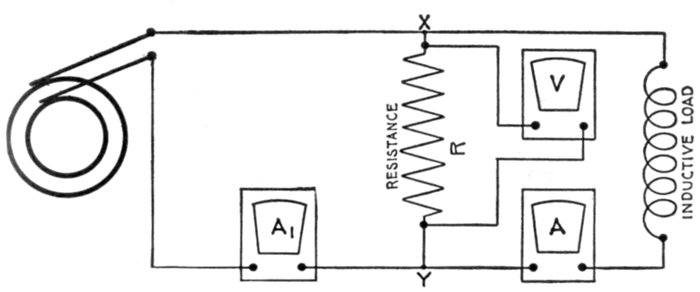

Fig. 1,266.—Inductance test, illustrating the self-induction of a coil which is gradually increased by moving an iron wire core

inch by inch into the coil. The current is kept constant with the adjustable resistance throughout the test and readings taken,

first without the iron core, and again when the core is put in the coil and moved to the 1, 2, 3, 4, etc., inch marks. By

plotting the voltmeter readings and the position of the iron core on section paper, a curve is obtained showing graphically

the effect of the self-induction. A curve of this kind is shown in fig. 1,302.

Ques. Define inductance.

Ans. It is the total magnetic flux

threading the circuit per unit current

which flows in the circuit, and which

produces the flux.

In this it must be understood that

if any portion of the flux thread the

circuit more than once, this portion

must be added in as many times as it

makes linkage.

Inductance, or the coefficient of self-induction

is the capacity which an

electric circuit has of producing induction

within itself.

Inductance is considered as the ratio

between the total induction through a

circuit to the current producing it.

Ques. What is the unit of inductance?

Ans. The henry.

Ques. Define the henry.

Ans. A coil has an inductance of

one henry when the product of the

number of lines enclosed by the coil

multiplied by the number of turns in

the coil, when a current of one ampere

is flowing in the coil, is equal to

100,000,000 or 108.

An inductance of one henry exists in

a circuit when a current changing at the

rate of one ampere per second induces a

pressure of one volt in the circuit.

[Pg 1031]

Ques. What is the henry called?

Ans. The coefficient of self-induction.

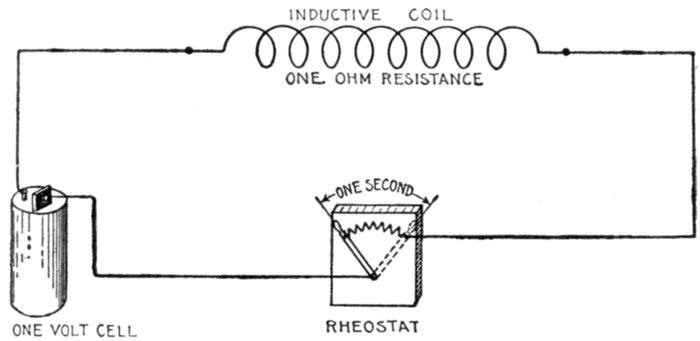

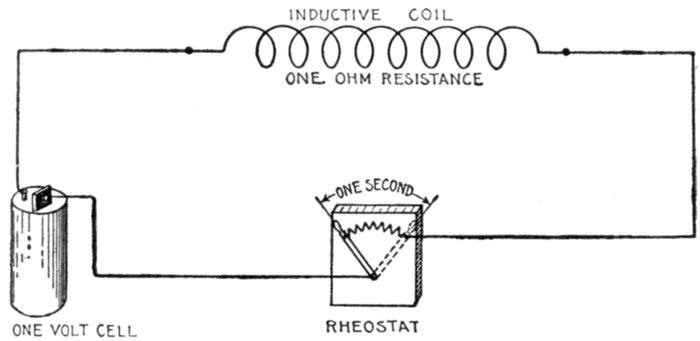

Fig. 1,267.—Diagram illustrating the henry. By definition: A circuit has an inductance of one

henry when a rate of change of current of one ampere per second induces a pressure of one

volt. In the diagram it is assumed that the internal resistance of the cell and resistance of

the connecting wires are zero.

The henry is the coefficient by which the time rate of change of the

current in the circuit must be multiplied, in order to give the pressure

of self-induction in the circuit.

The formula for the henry is as follows:

or

where

- L = coefficient of self induction in henrys;

- N = total number of lines of force threading a coil when the current is one ampere;

- T = number of turns of coil.

If a coil had a coefficient of self-induction of one henry, it would mean

that if the coil had one turn, one ampere would set up 100,000,000, or

108, lines through it.

[Pg 1032]

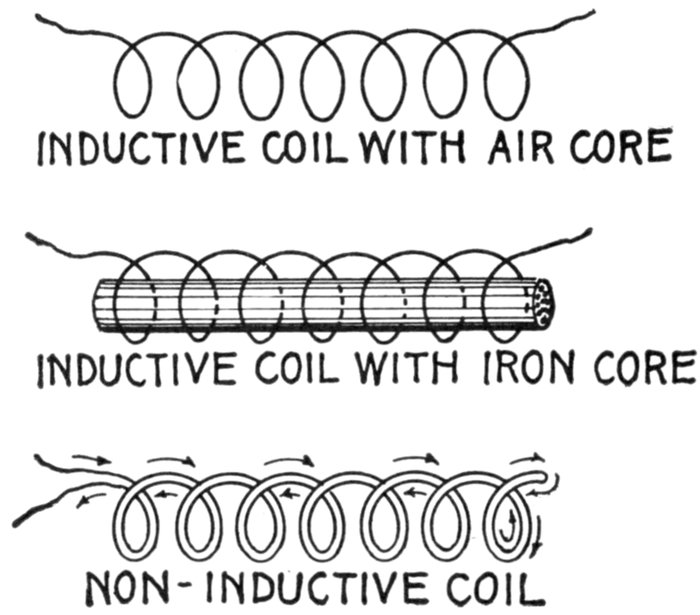

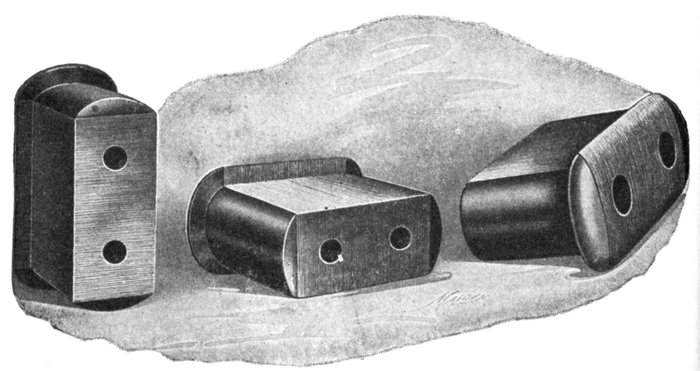

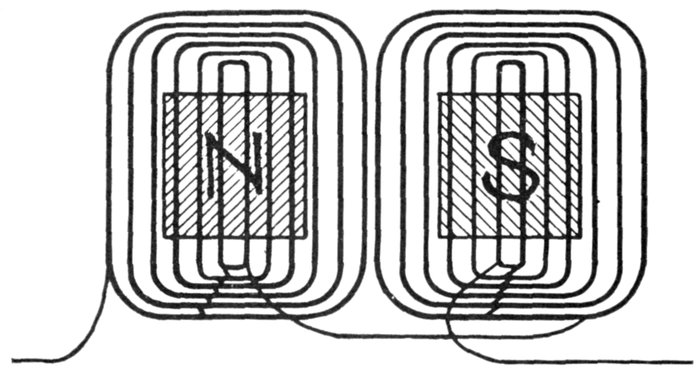

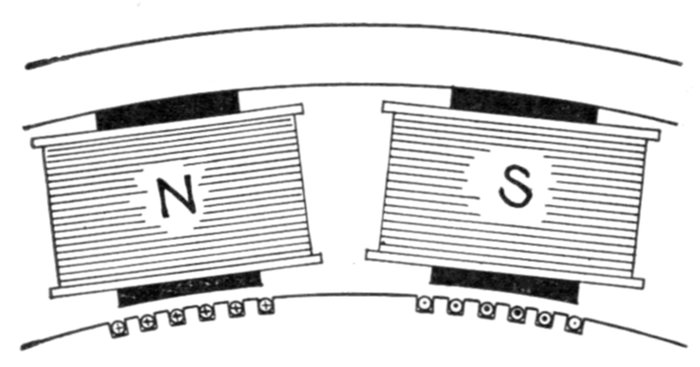

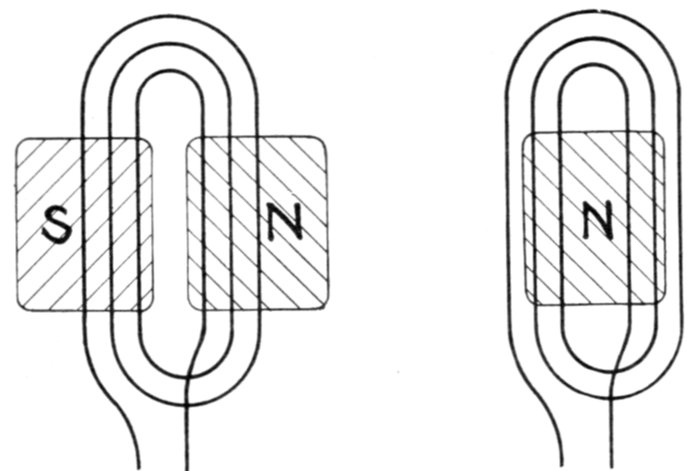

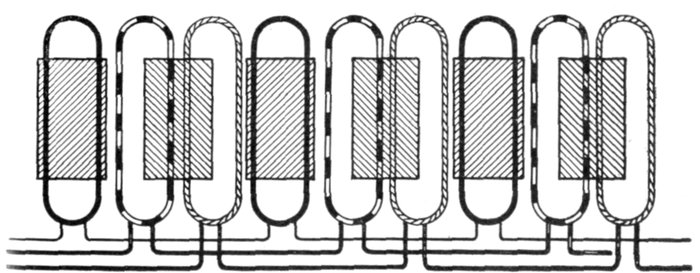

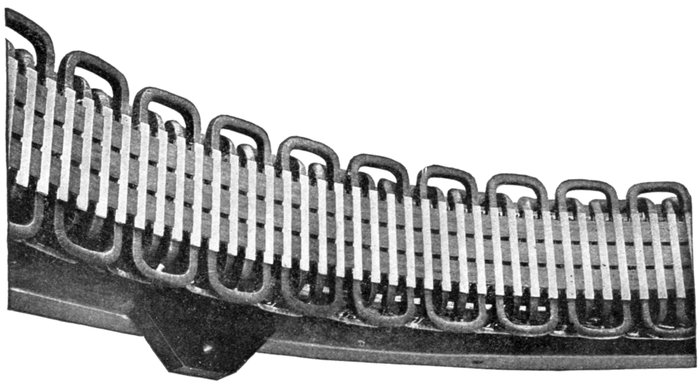

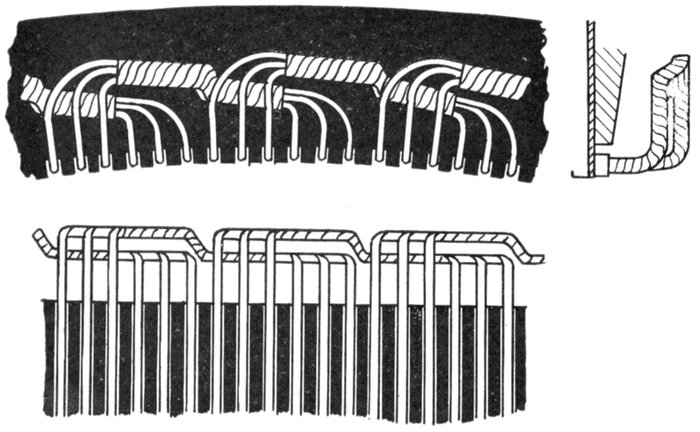

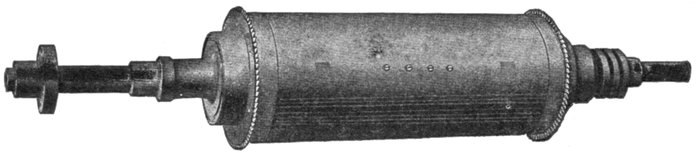

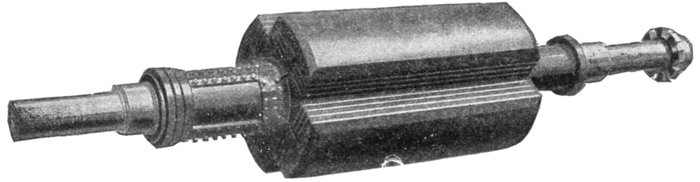

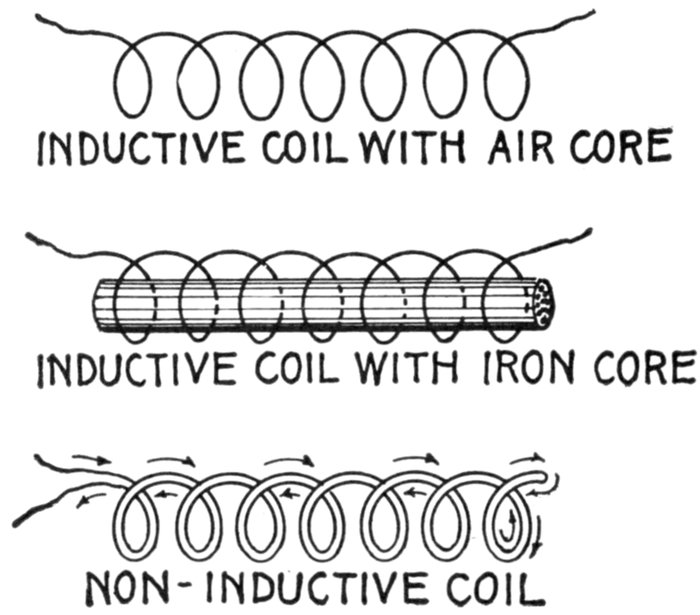

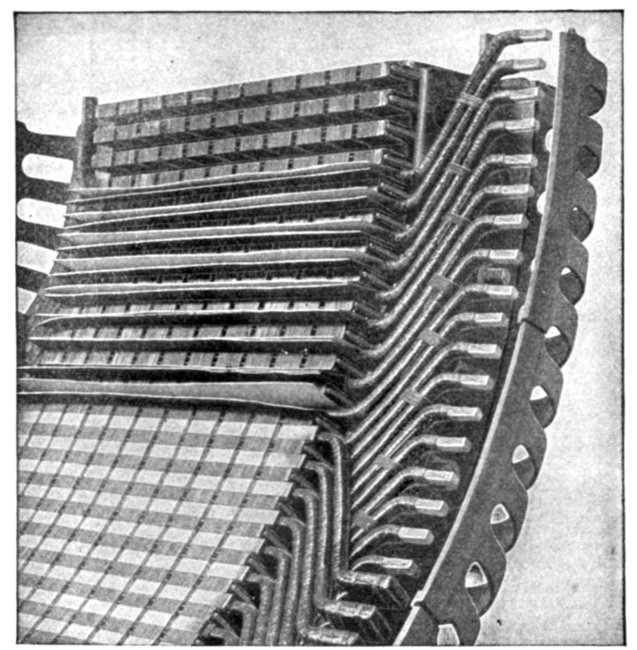

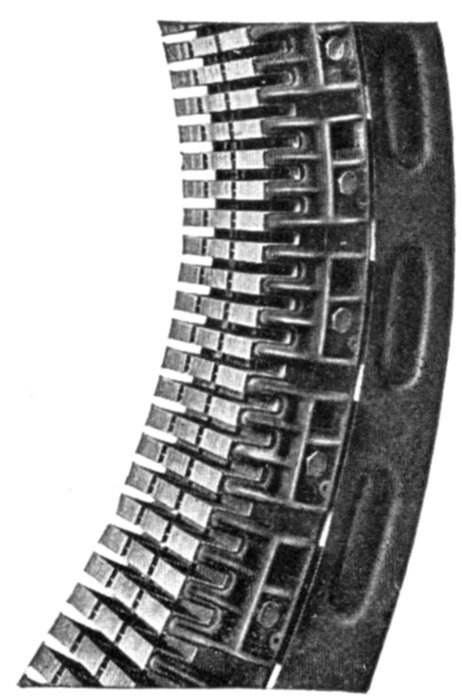

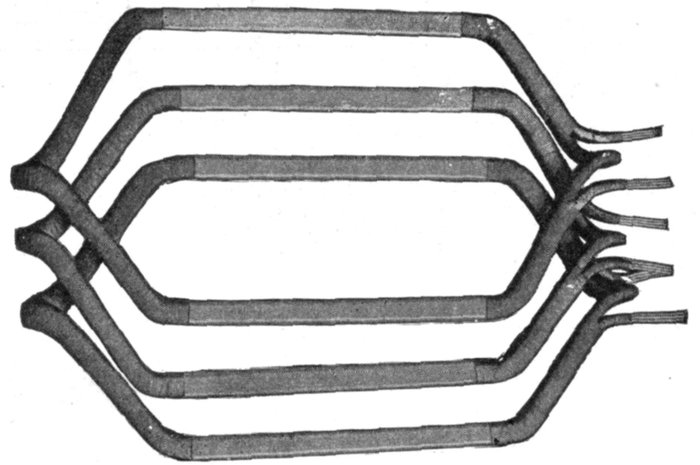

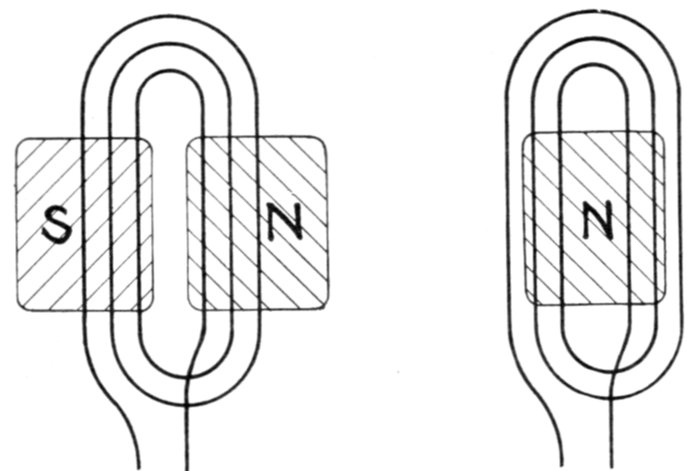

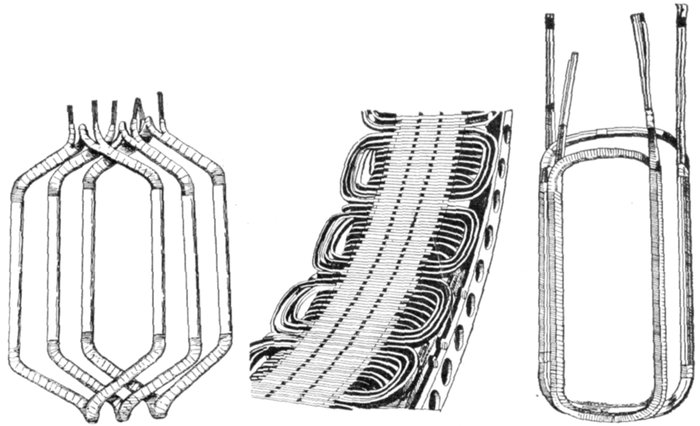

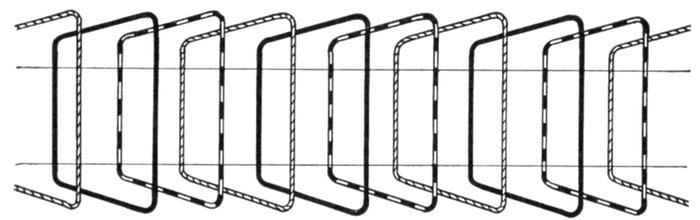

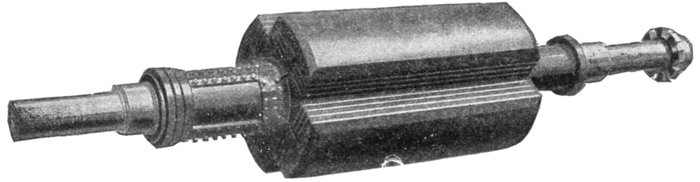

Figs. 1,268 to 1,270.—Various coils. The inductance effect, though perceptible in an air core

coil, fig. 1,268, may be greatly intensified by inserting a core made of numerous pieces

of iron wire, as in fig. 1,269. Fig. 1,270 shows a non-inductive coil. When wound in this

manner, a coil will have little or no inductance because each half of the coil neutralizes

the magnetic effect of the other. This coil, though non-inductive, will have "capacity."

It would be useless for solenoids or electromagnets, as it would have no magnetic field.

The henry[2] is too large a unit for use in practical computations,

which involves that the millihenry, or 1/1,000th

henry, is the accepted unit. In pole suspended lines the

inductance varies as the metallic resistance, the distance between

the wires on the cross arm and the number of cycles per second,

as indicated by accepted tables. Thus, for one mile of No.

8 B. & S. copper wire, with a resistance of 3,406 ohms, the coefficient

of self-induction with 6 inches between centers is .00153, and, with 12 inches, .00175.

[Pg 1033]

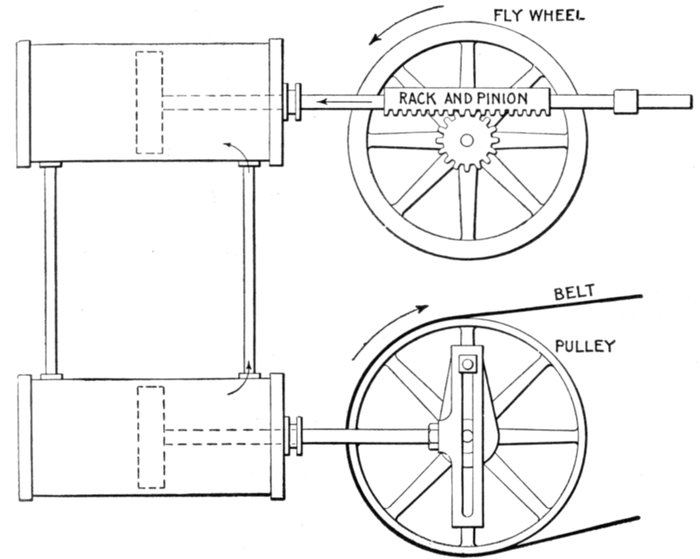

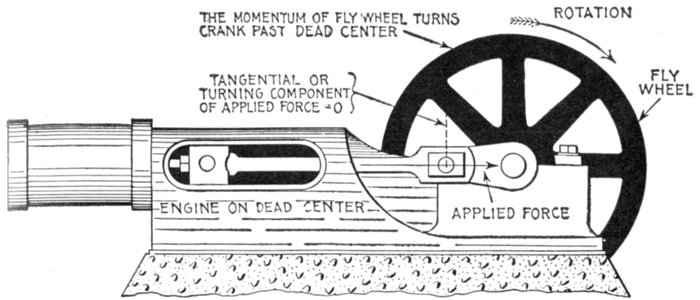

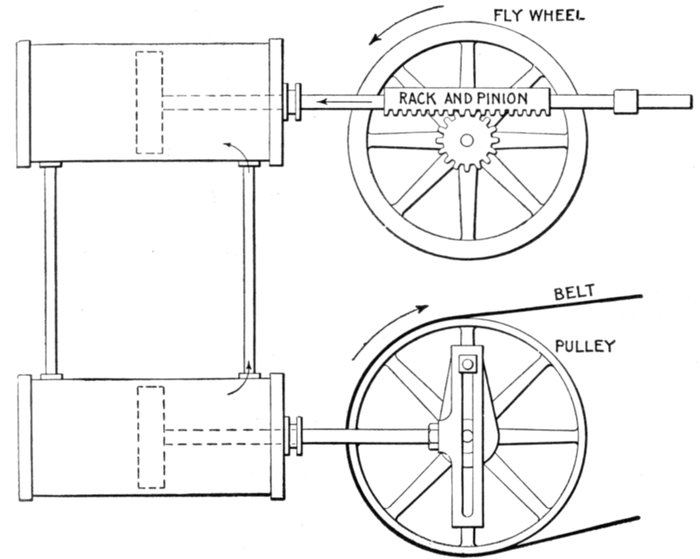

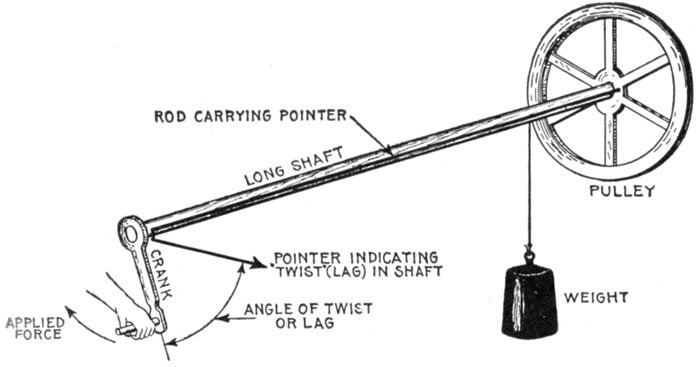

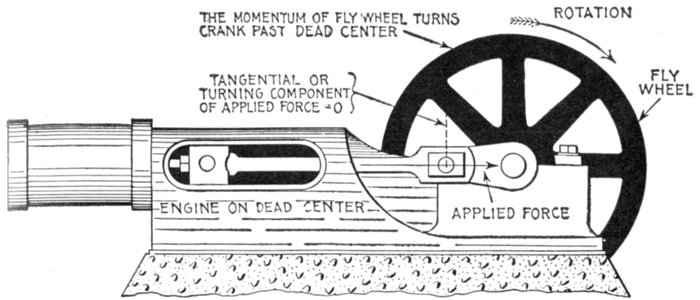

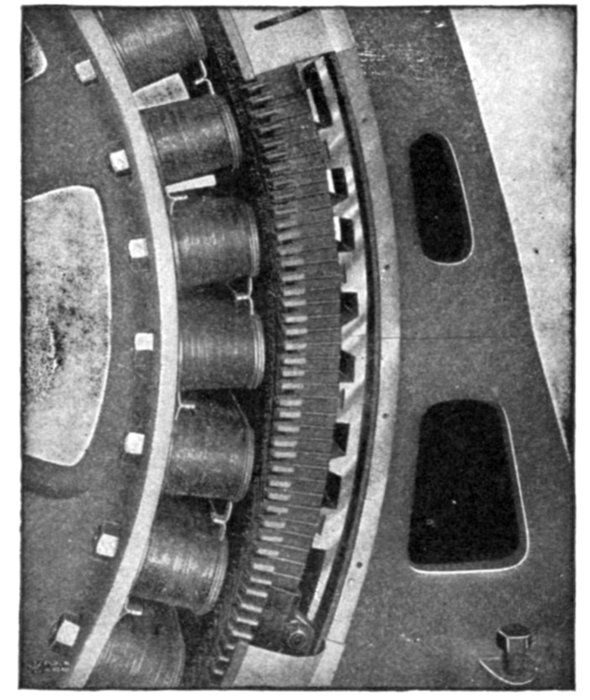

Fig. 1,271.—Hydraulic-mechanical analogy illustrating inductance in an alternating current circuit.

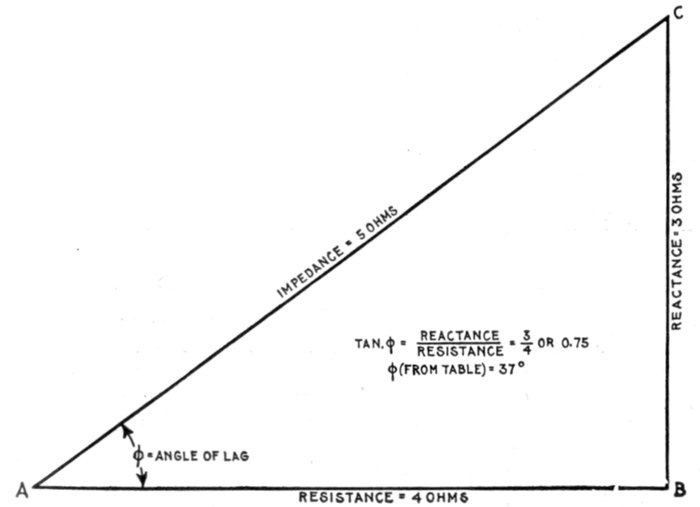

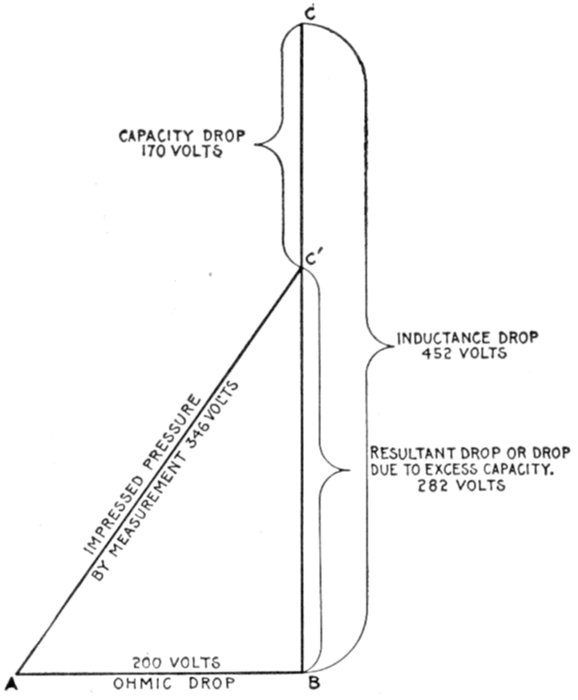

The two cylinders are connected at their ends by the vertical pipes, each being

provided with a piston and the system filled with water. Reciprocating motion is imparted

to the lower pulley by Scotch yoke connection with the drive pulley. The upper

piston is connected by rack and pinion gear with a fly wheel. In operation, the to and fro

movement of the lower piston produces an alternating flow of water in the upper cylinder

which causes the upper piston to move back and forth. The rack and pinion connection

with the fly wheel causes the latter to revolve first in one direction, then in the other, in

step with the upper piston. The inertia of the fly wheel causes it to resist any change

in its state, whether it be at rest or in motion, which is transmitted to the upper piston,

causing it to offer resistance to any change in its rate or direction of motion. Inductance

in the alternating current circuit has precisely the same effect, that is, it opposes any

change in the strength or direction of the current.

[Pg 1034]

Ques. How does the inductance of a coil vary with

respect to the core?

Ans. It is least with an air core; with an iron core, it is

greater in proportion to the permeability[3] of the iron.

The coefficient L for a given coil is a constant quantity so long as the

magnetic permeability of the material surrounding the coil does not

change. This is the case where the coil is surrounded by air. When

iron is present, the coefficient L is practically constant, provided the magnetism

is not forced too high.

In most cases arising in practice, the coefficient L may be considered

to be a constant quantity, just as the resistance R is usually considered

constant. The coefficient L of a coil or circuit is often spoken of as its

inductance.

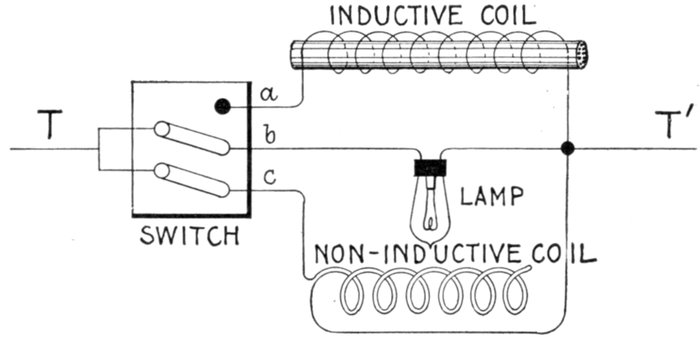

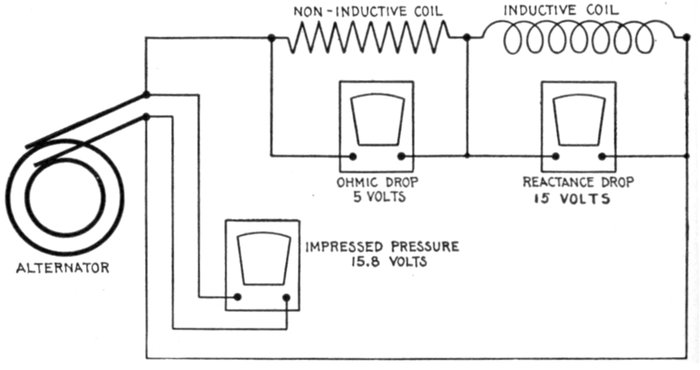

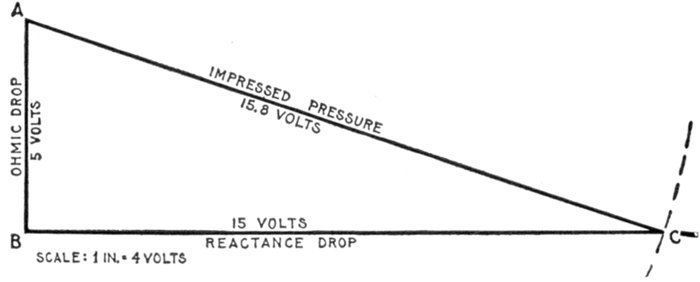

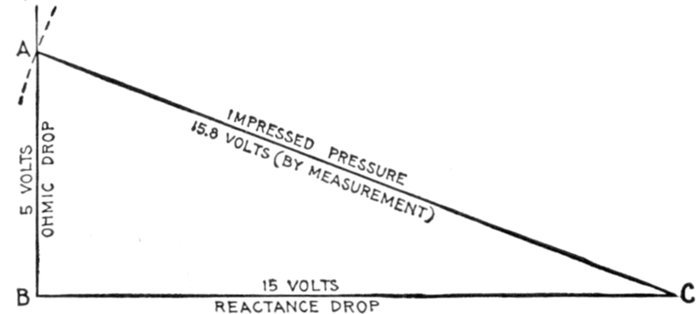

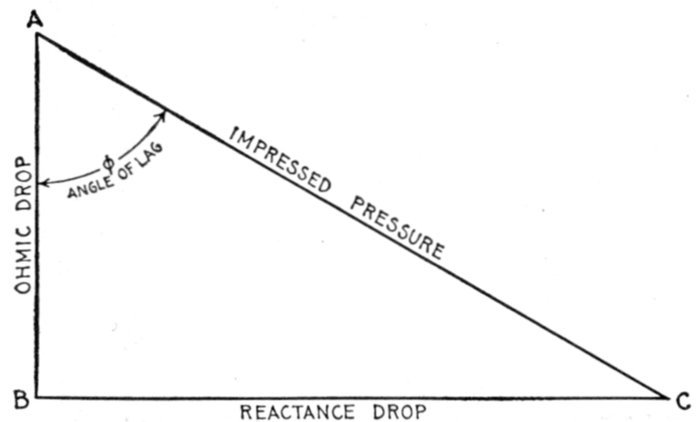

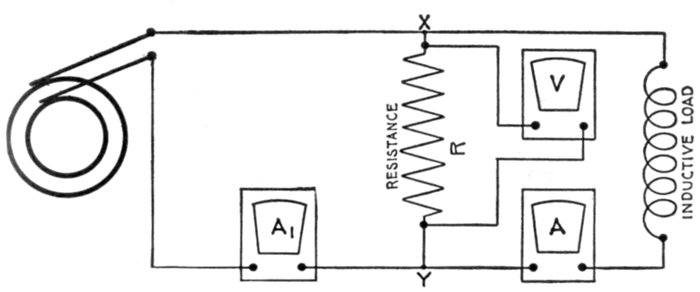

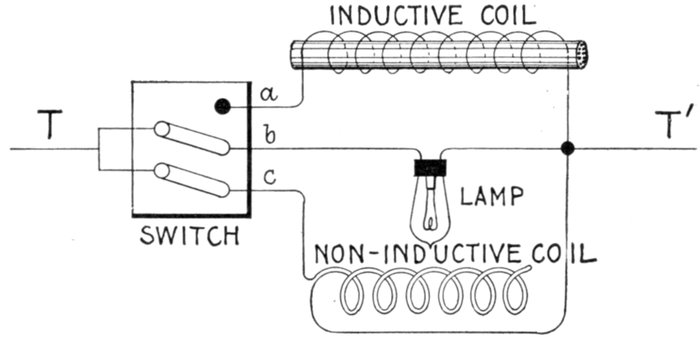

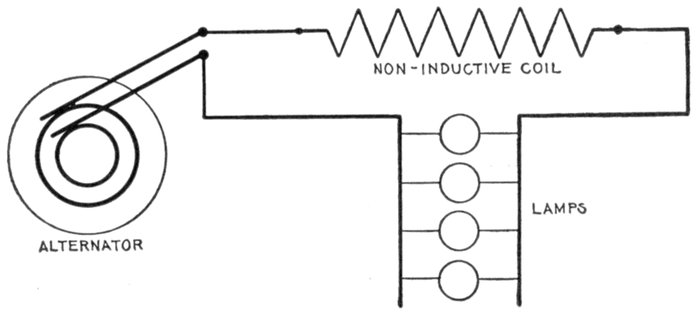

Fig. 1,272.—Experiment showing effect of inductive and non-inductive coils in alternating

current circuit. The apparatus is connected up as shown; by means of the switch, the

lamp may be placed in parallel with either the inductive or non-inductive coil. These

coils should have the same resistance. Pass an alternating current through the lamp

and non-inductive coil, of such strength that the lamp will be dimly lighted. Now turn

the switch so as to put the lamp and inductive coil in parallel and the lamp will burn

with increased brilliancy. The reason for this is because of the opposition offered

by the inductive coil to the current, less current is shunted from the lamp when

the inductive coil is in the circuit than when the non-inductive coil is in the circuit. That

is, each coil has the same ohmic resistance, but the inductive coil has in addition the

spurious resistance due to inductance, hence it shunts less current from the lamp than

does the non-inductive coil.

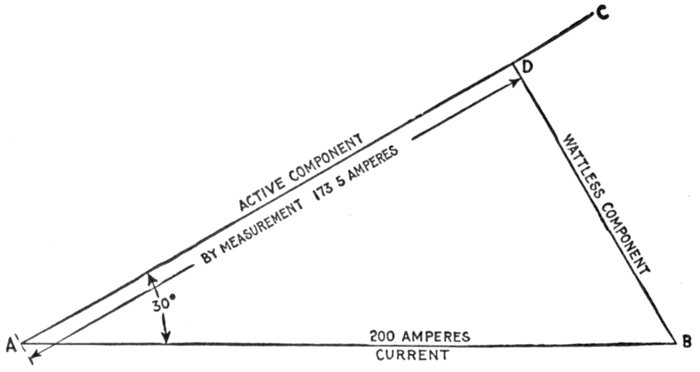

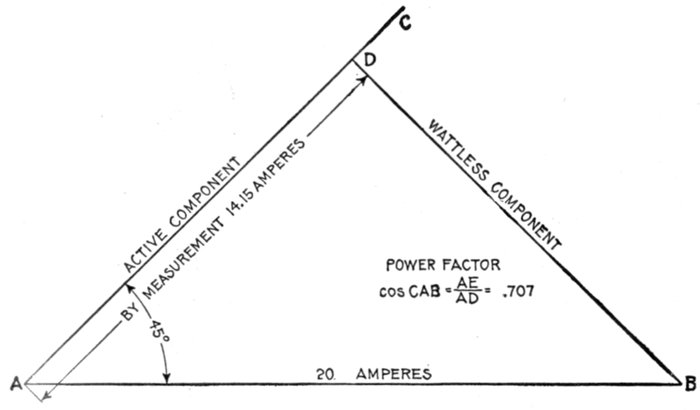

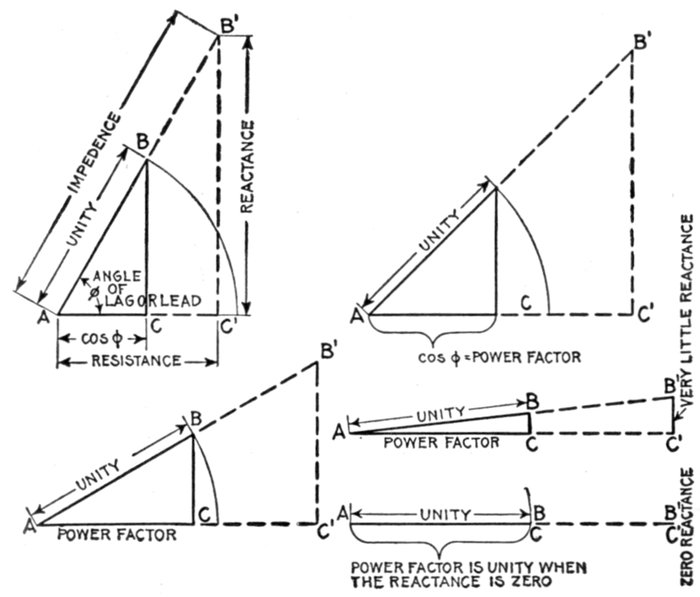

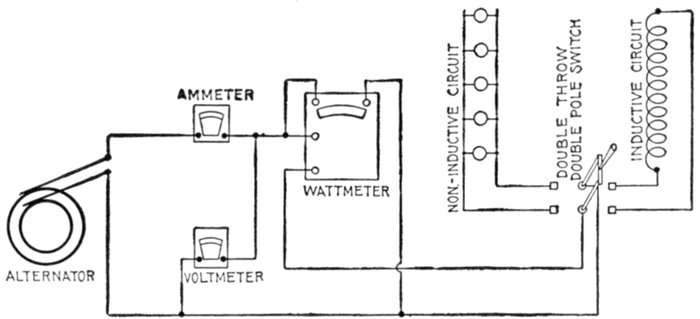

[Pg 1035]

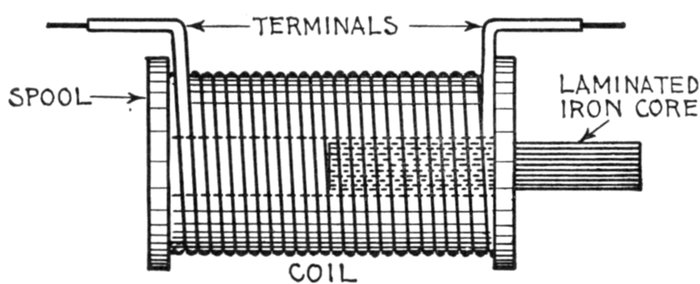

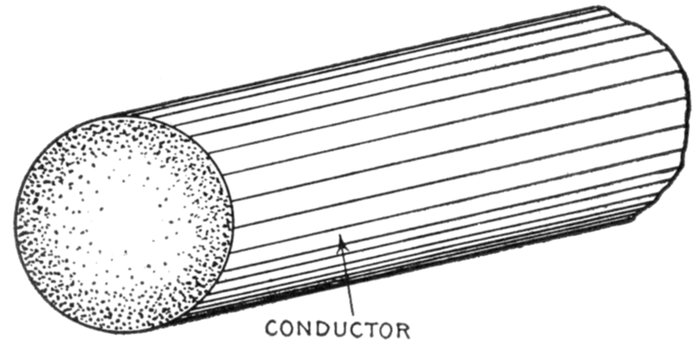

Ques. Why is the iron core of an inductive coil made

with a number of small wires instead of one large rod?

Ans. It is laminated in order to reduce eddy currents and

consequent loss of energy, and to prevent excessive heating of

the core.

Ques. How does the number of turns of a coil affect

the inductance?

Ans. The inductance varies as the square of the turns.

That is, if the turns be doubled, the inductance becomes four times

as great.

The inductance of a coil is easily calculated from the following

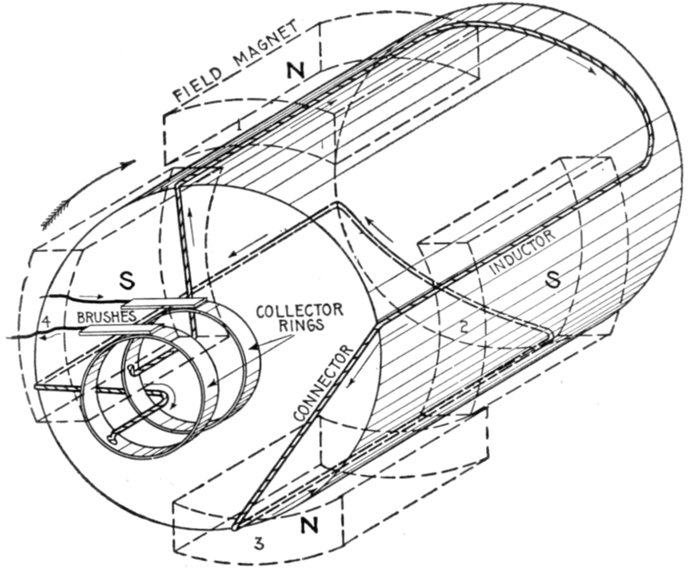

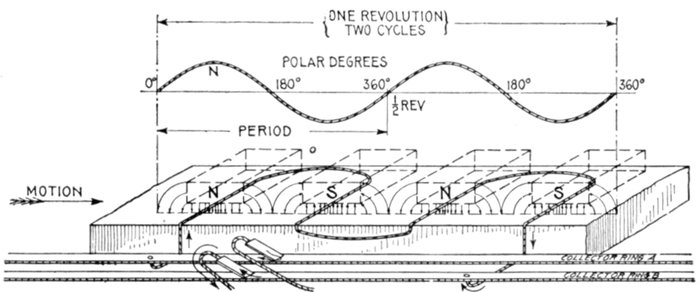

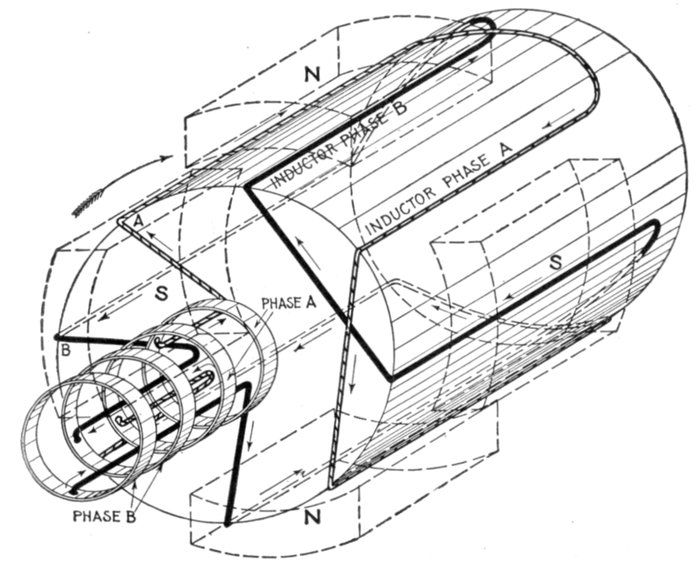

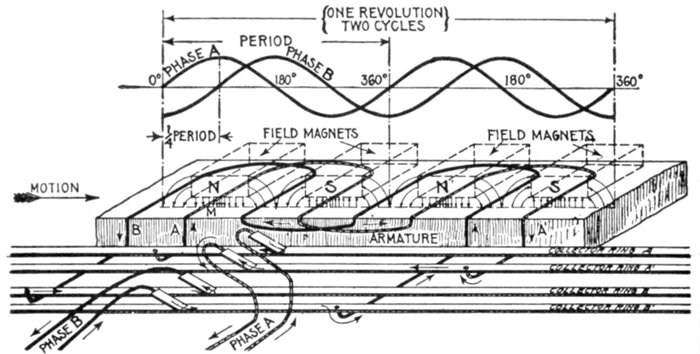

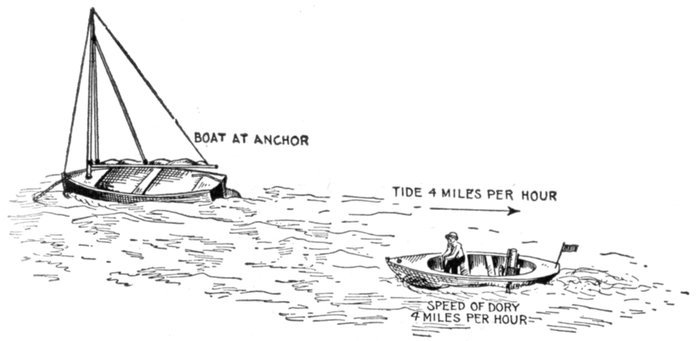

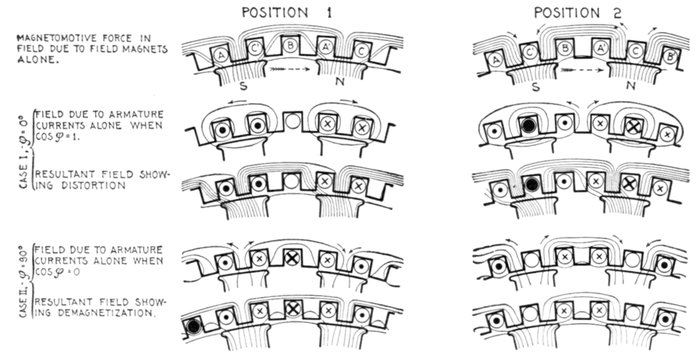

formulæ:

L = 4π2r2n2 ÷ (l × 109) (1)

for a thin coil with air core, and

L = 4π2r2n2μ ÷ (l × 109) (2)

for a coil having an iron core. In the above formulæ:

- L = inductance in henrys;

- π = 3.1416;

- r = average radius of coil in centimeters;

- n = number of turns of wire in coil;

- μ = permeability of iron core;

- l = length of coil in centimeters.

EXAMPLE.—An air core coil has an average radius of 10 centimeters

and is 20 centimeters long, there being 500 turns, what is the

inductance?

Substituting these values in formula (1)

L = 4 × (3.1416)2 × 102 × 5002 ÷ (20 × 109) = .00494 henry

[Pg 1036]

Ques. Is the answer in the above example in the

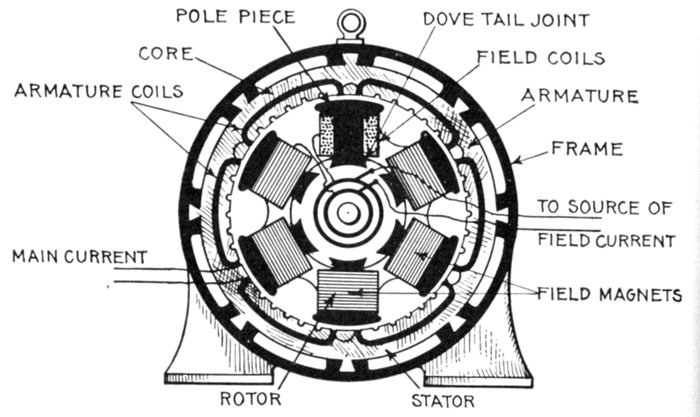

customary form?

Ans. No; the henry being a very large unit, it is usual to

express inductance in thousandths of a henry, that is, in milli-henrys.

The answer then would be .04935 × 1,000 = 49.35 milli-henrys.

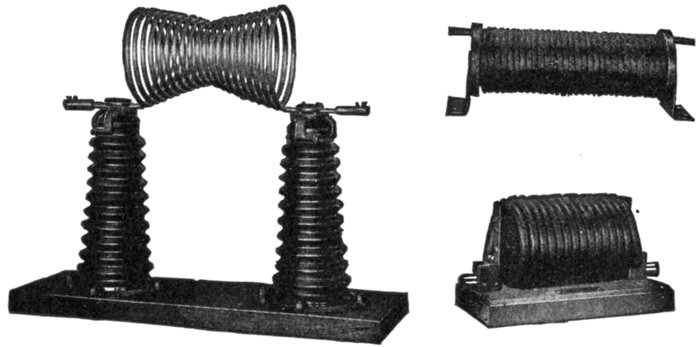

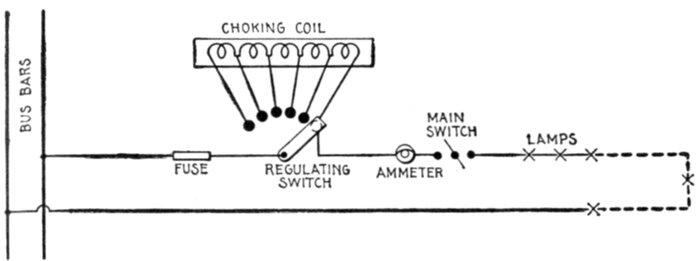

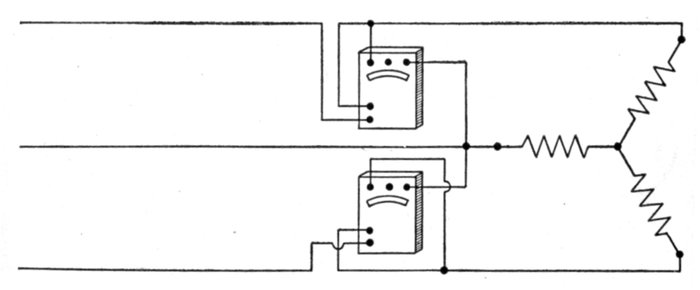

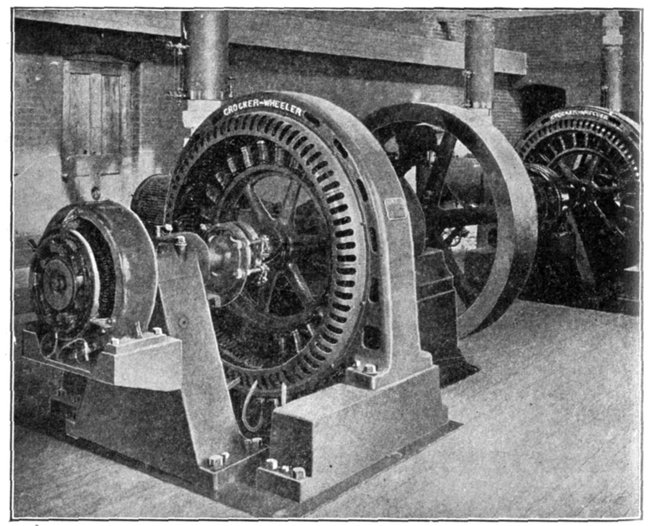

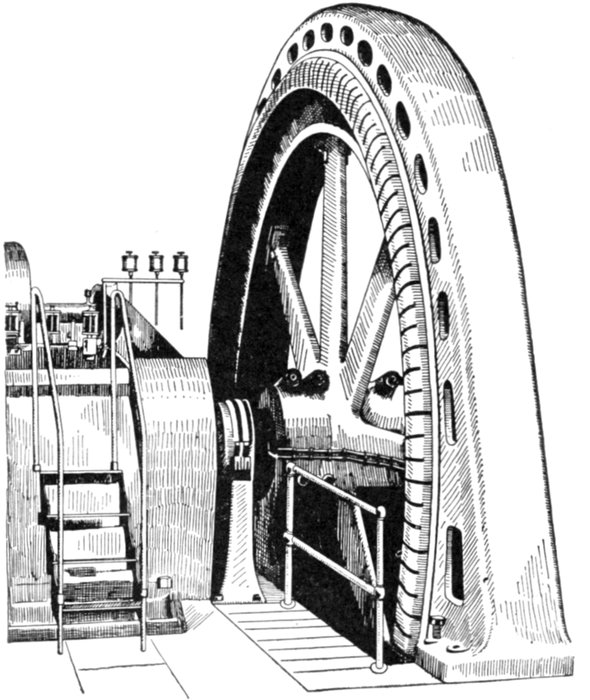

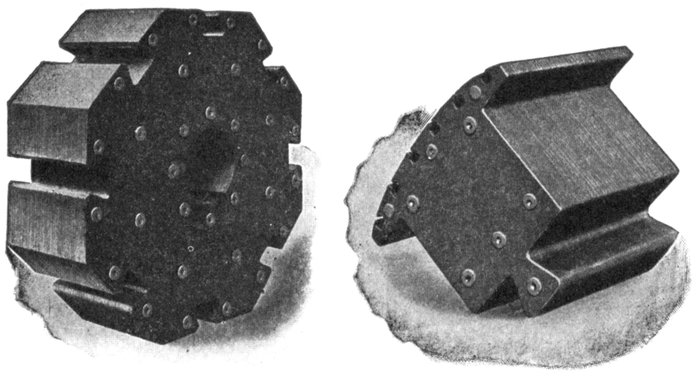

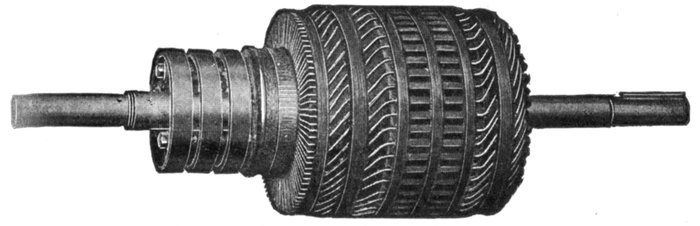

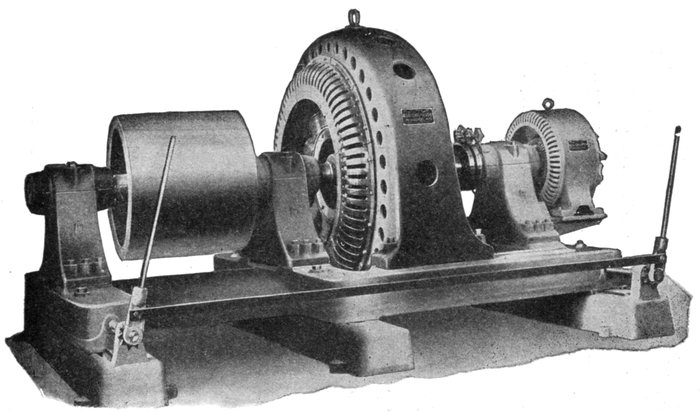

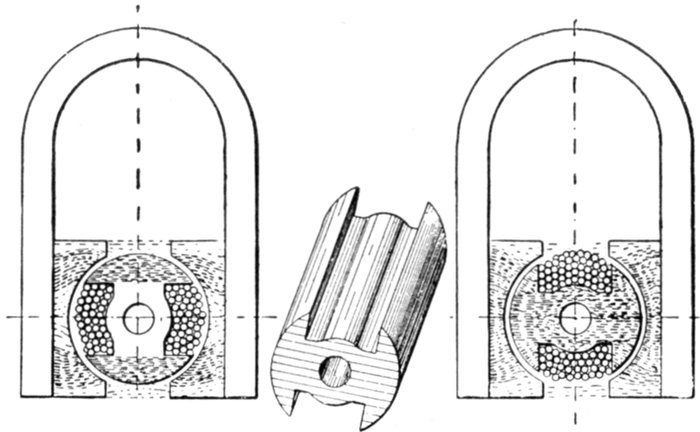

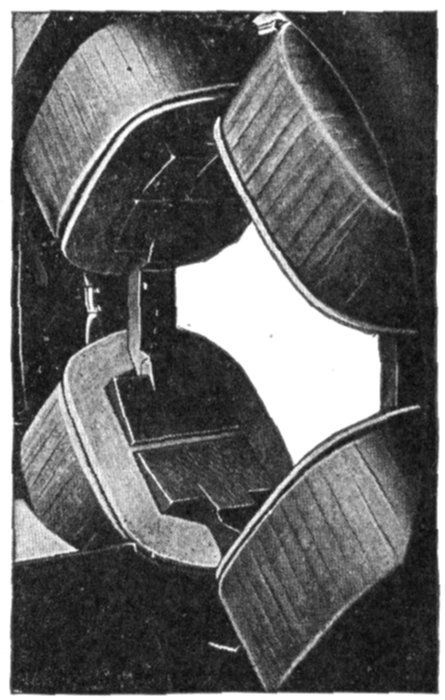

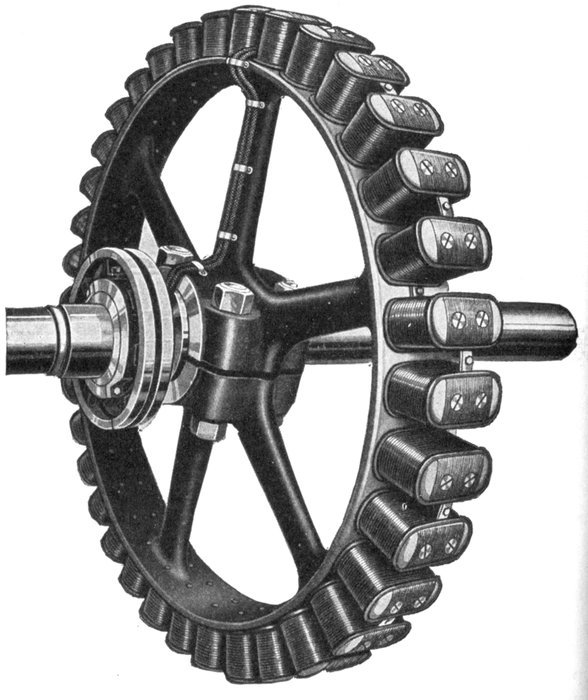

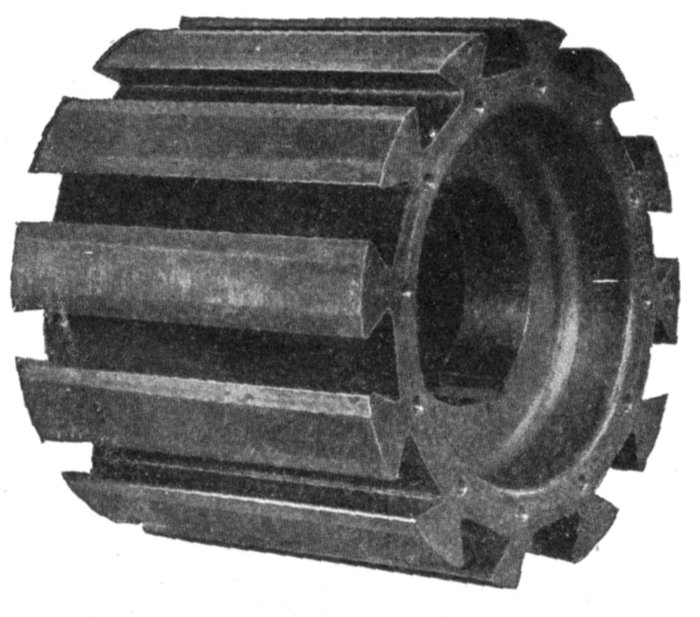

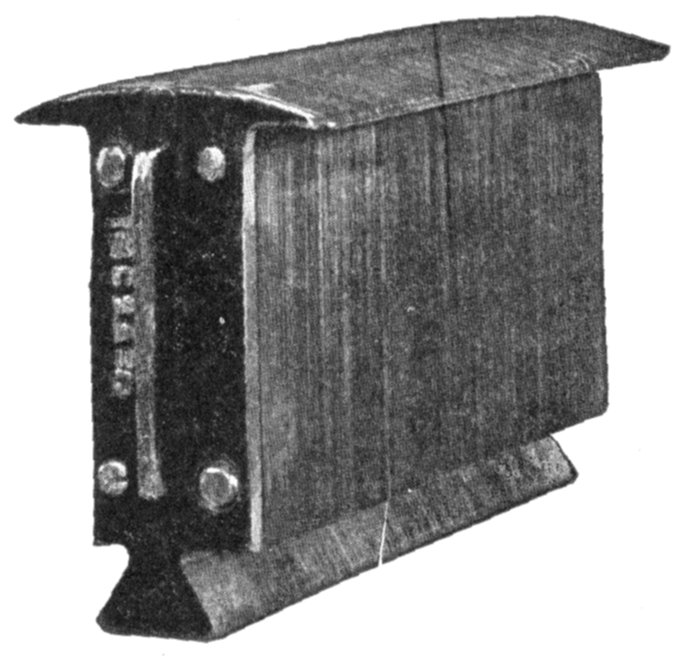

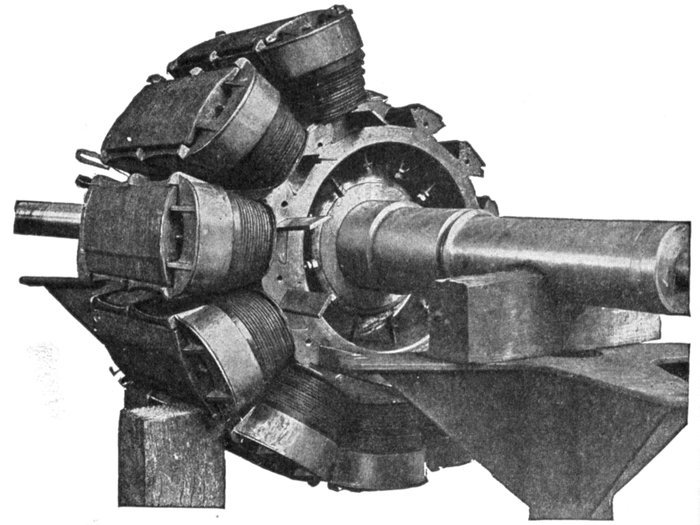

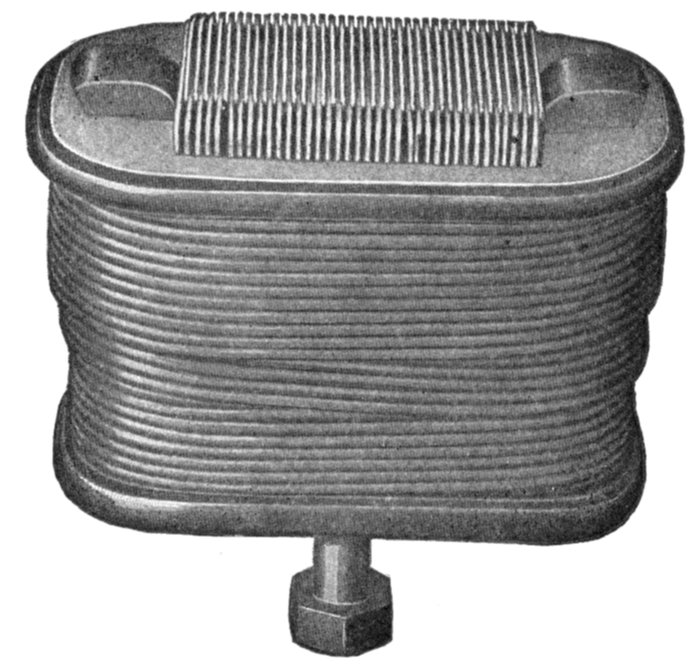

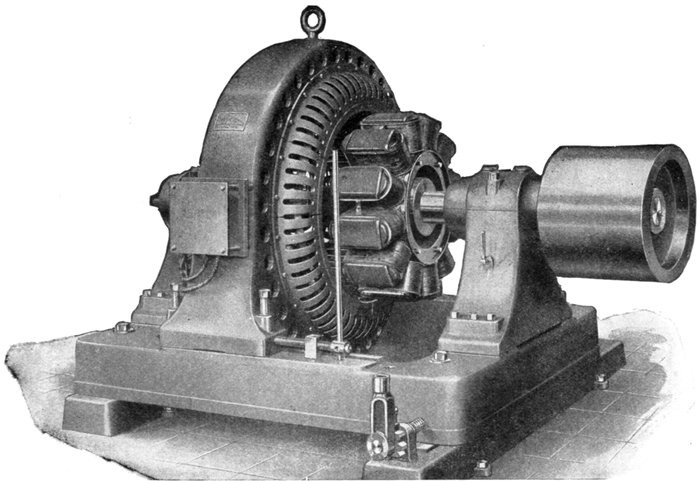

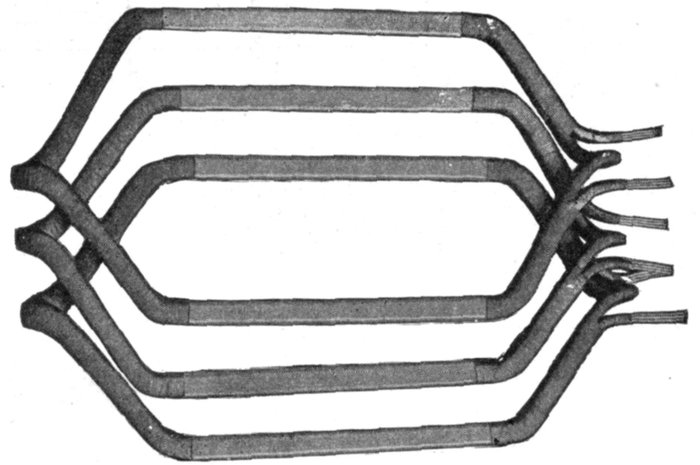

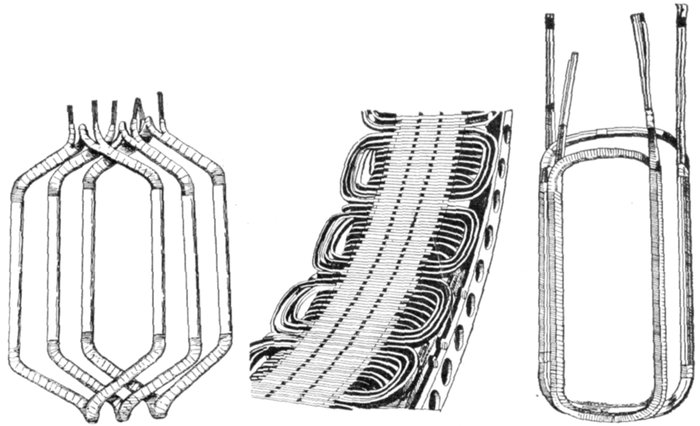

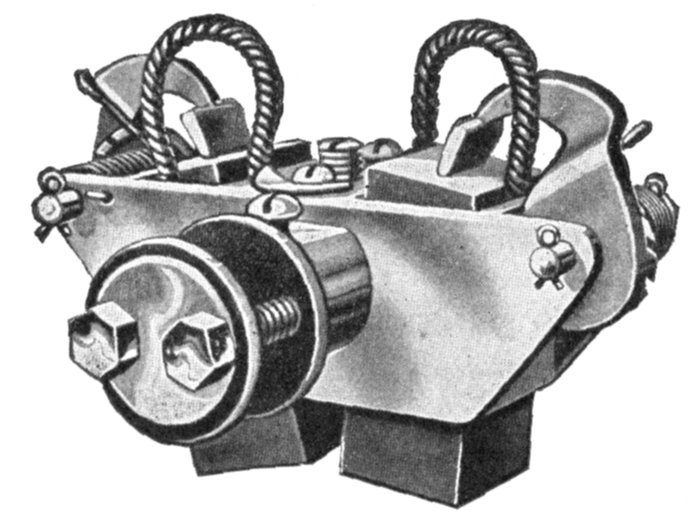

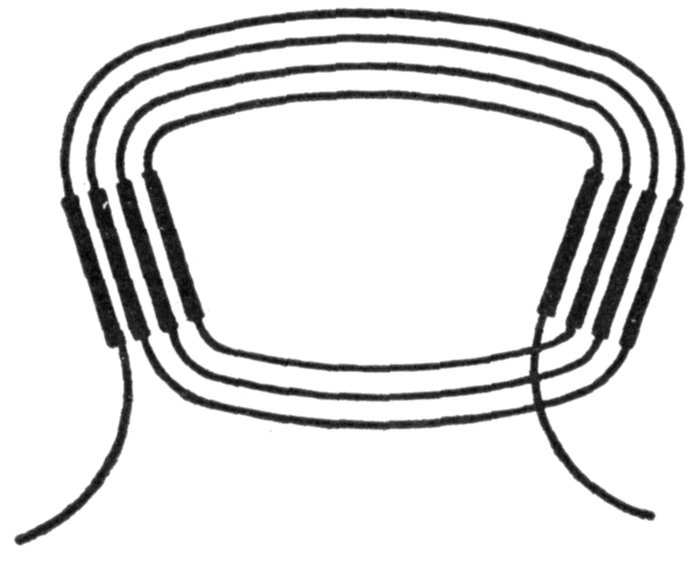

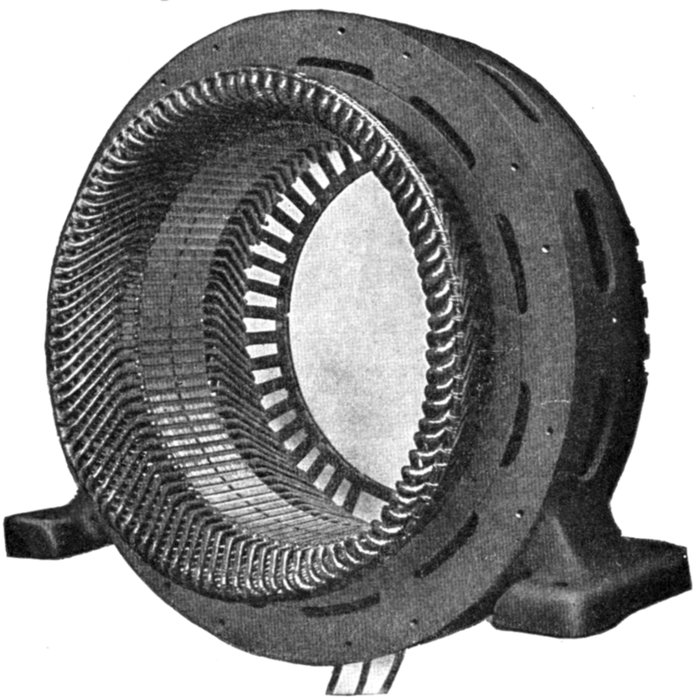

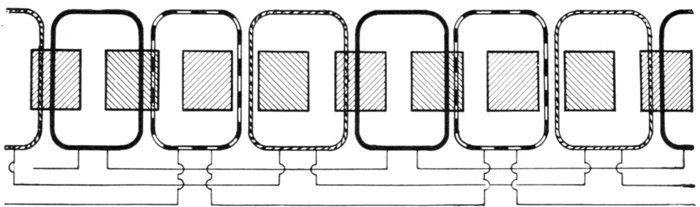

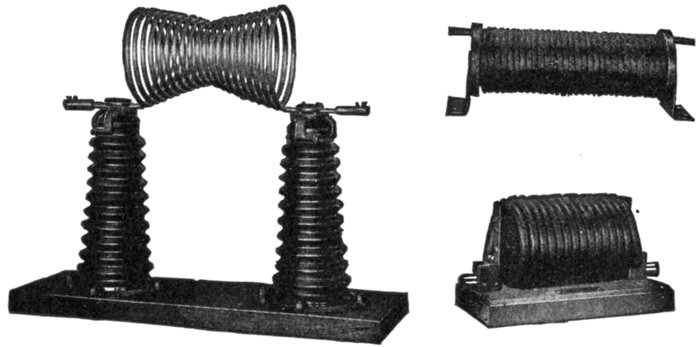

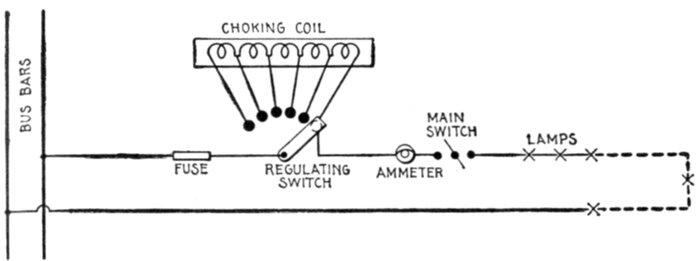

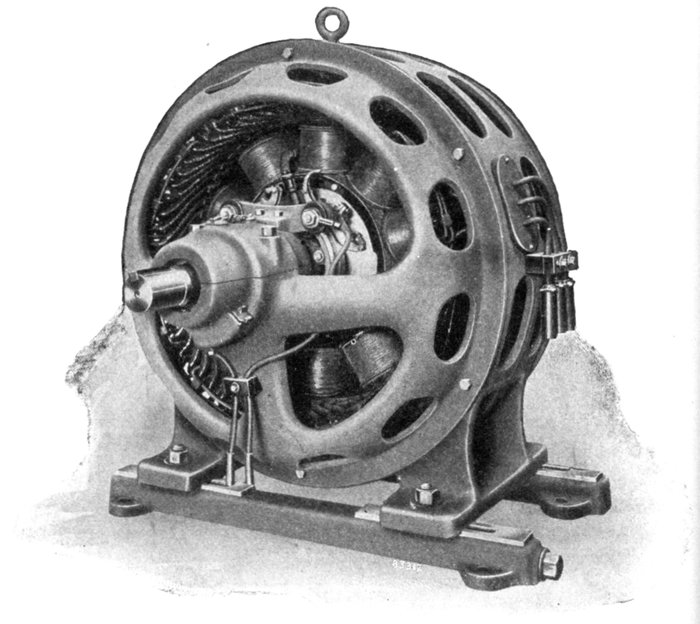

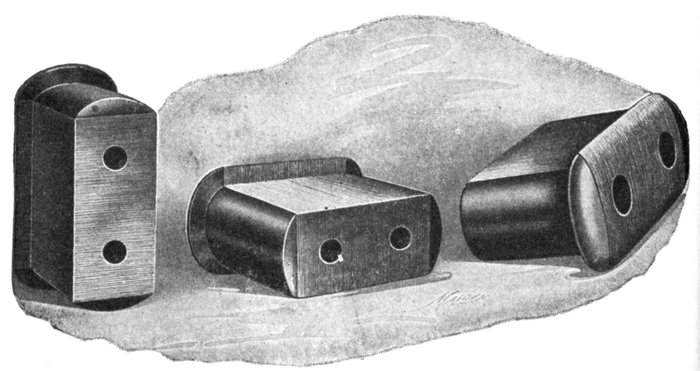

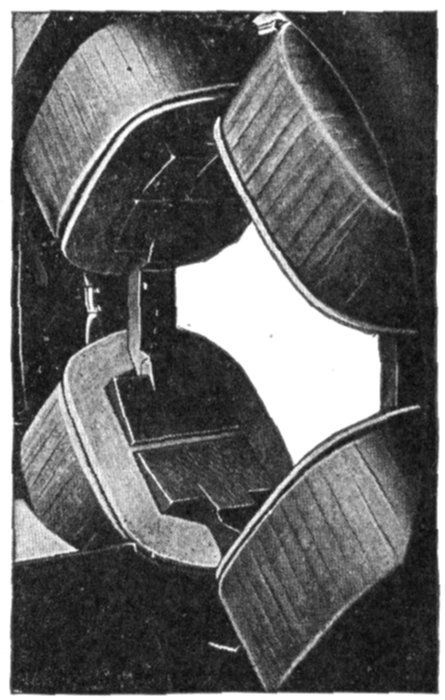

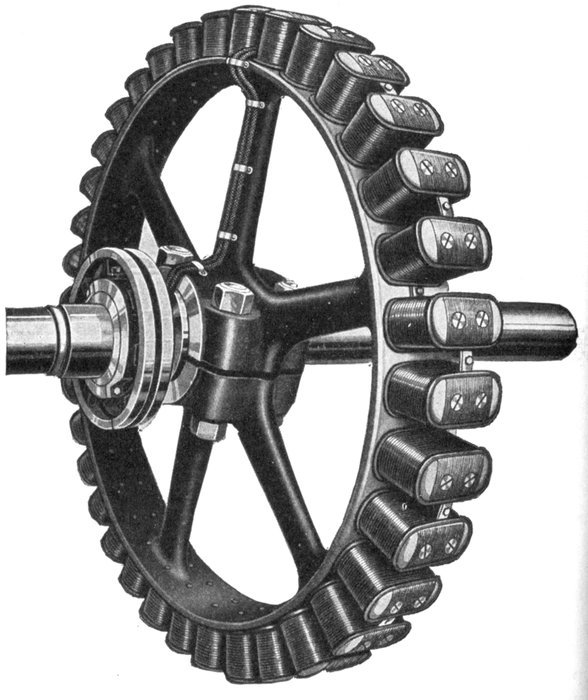

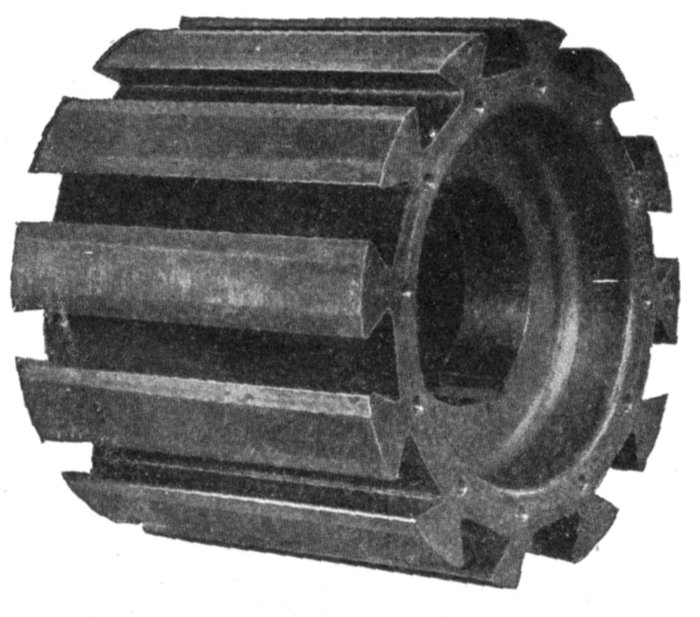

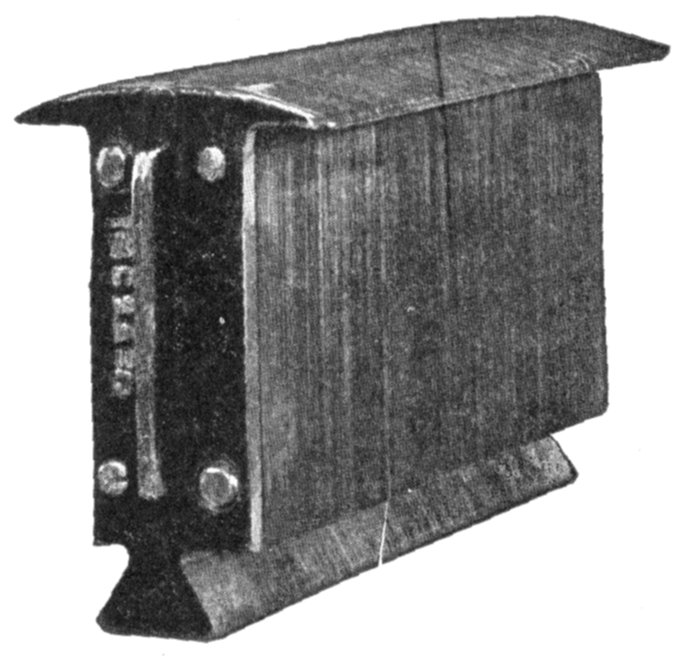

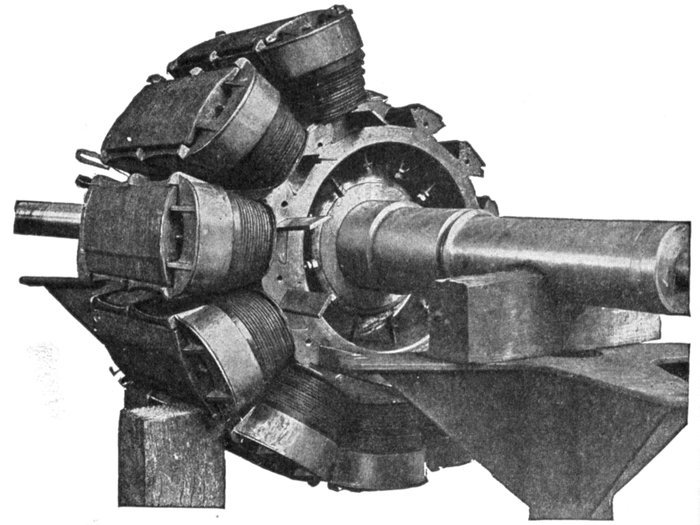

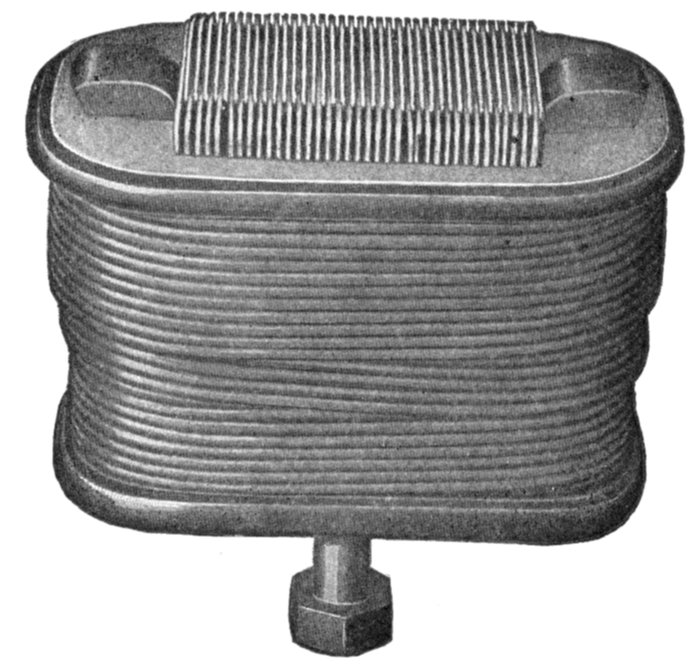

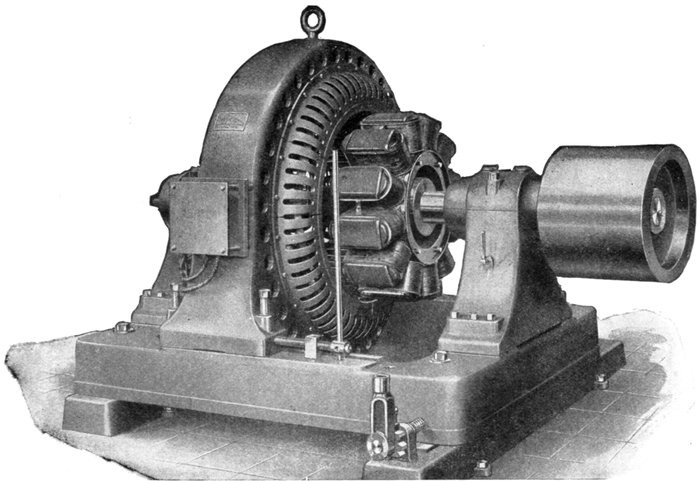

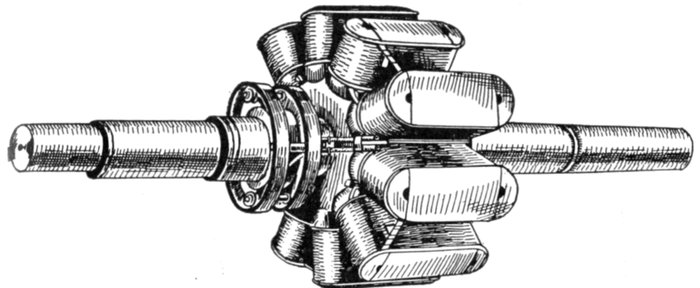

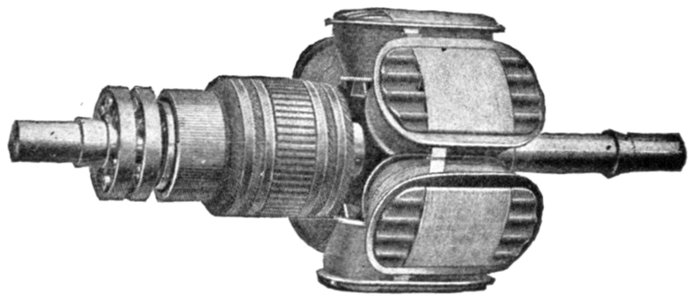

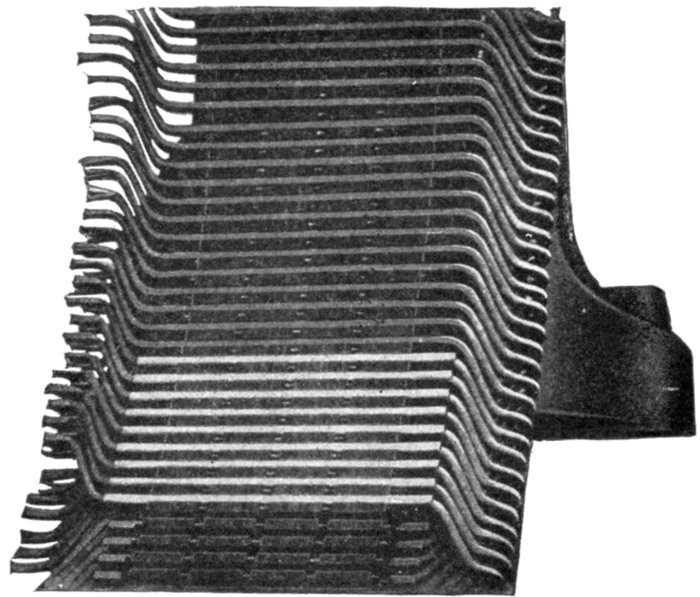

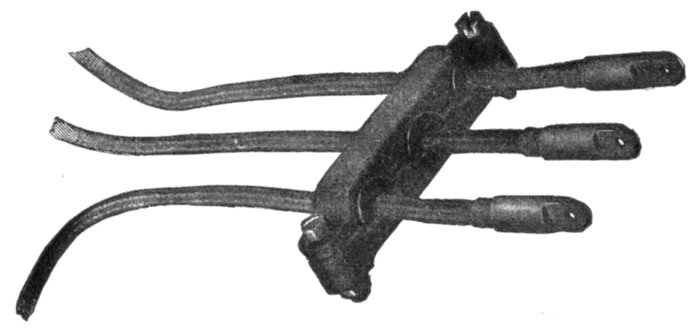

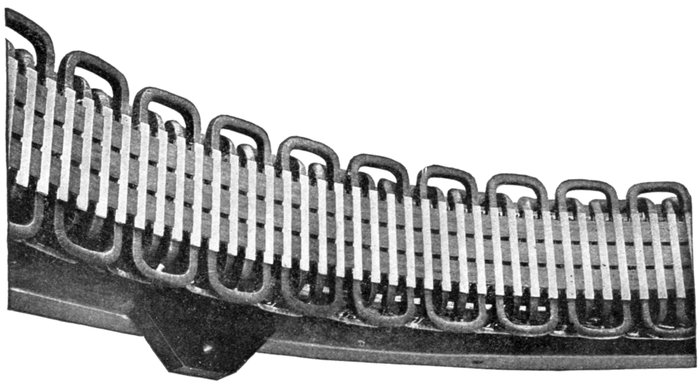

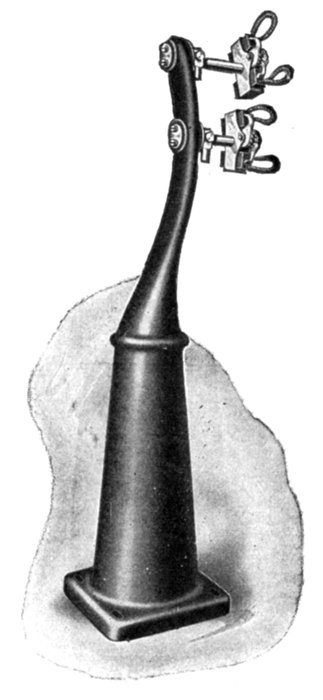

Figs. 1,273 to 1,275.—General Electric choke coils. Fig. 1,273, hour glass coil, 35,000 volts;

fig. 1,274, 4,600 volt coil; fig. 1,275, 6,600 volt coil. A choke coil is a coil with large

inductance and small resistance, used to impede alternating currents. The choke coil is

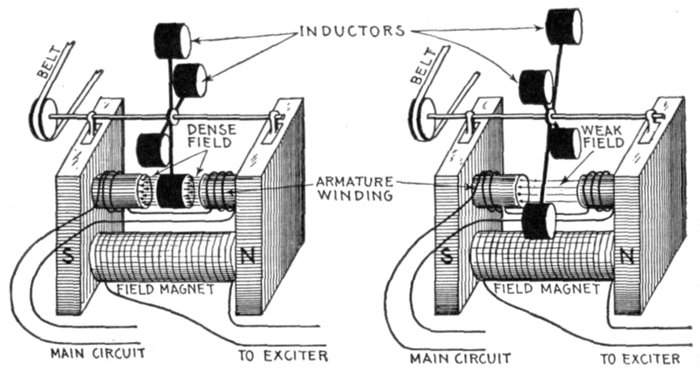

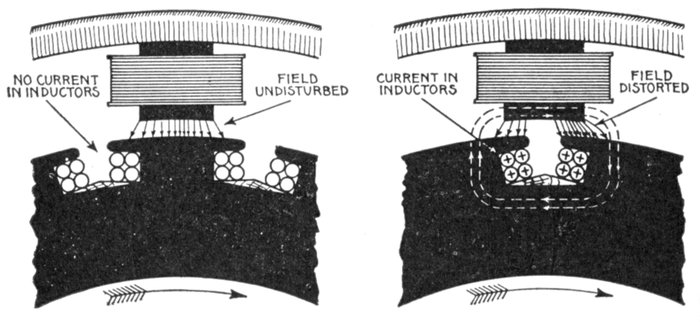

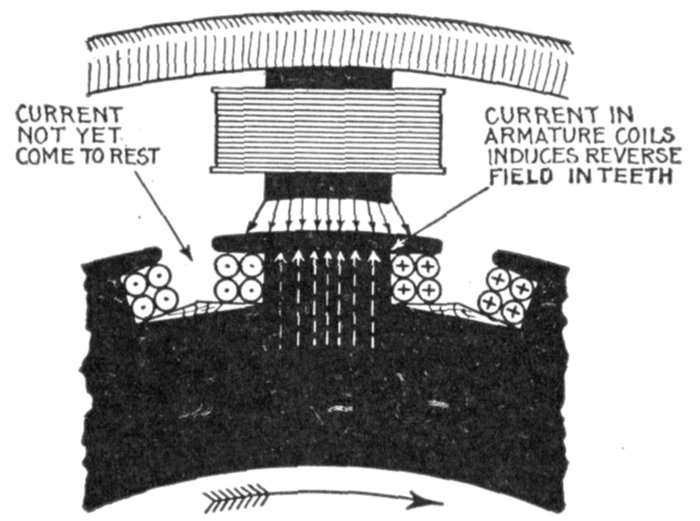

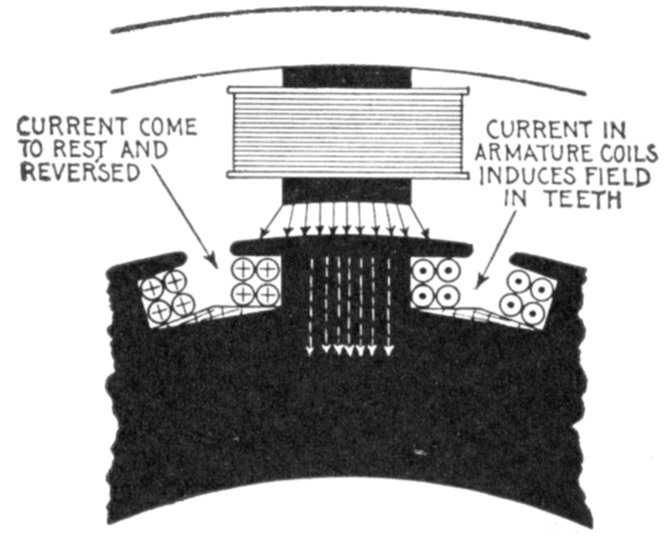

used extensively as an auxiliary to the lightning arrester. In this connection the

primary objects of the choke coil should be: 1, to hold back the lightning disturbance

from the transformer or generator until the lightning arrester discharges to earth.

If there be no lightning arrester the choke coil evidently cannot perform this function.

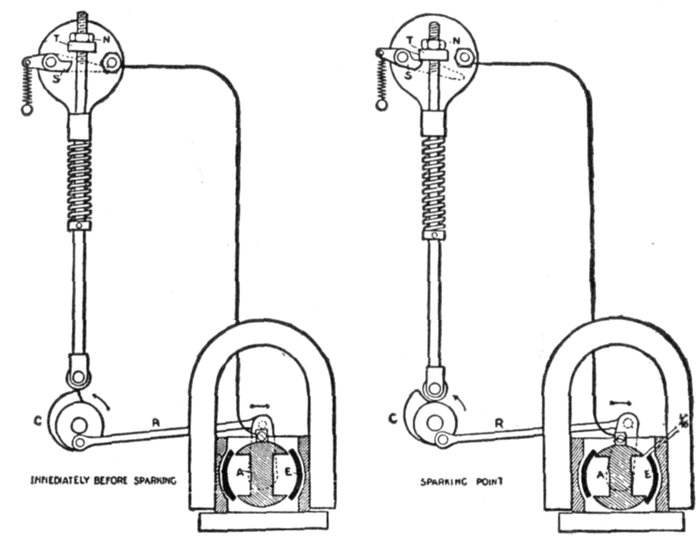

2, to lower the frequency of the oscillation so that whatever charge gets through the

choke coil will be of a frequency too low to cause a serious drop of pressure around the

first turns of the end coil in either generator or transformer. Another way of expressing

this is from the standpoint of wave front: a steep wave front piles up the pressure when

it meets an inductance. The second function of the choke coil is, then, to smooth out

the wave front of the surge. The principal electrical condition to be avoided is that of

resonance. The coil should be so arranged that if continual surges be set up in the

circuit, a resonant voltage due to the presence of the choke coil cannot build up at the

transformer or generator terminals. In the types shown above, the hour glass coil has

the following advantages on high voltages: 1, should there be any arcing between

adjacent turns the coils will re-insulate themselves, 2, they are mechanically strong, and

sagging is prevented by tapering the coils toward the center turns, 3, the insulating

supports can be best designed for the strains which they have to withstand. Choke

coils should not be used in connection with cable systems.

EXAMPLE.—An air core coil has an inductance of 50 milli-henrys;

if an iron core, having a permeability of 600 be inserted, what is the

inductance?

The inductance of the air core coil will be multiplied by the permeability

of the iron; the inductance then is increased to

50 × 600 = 30,000 milli-henrys, or 30 henrys.

[Pg 1037]

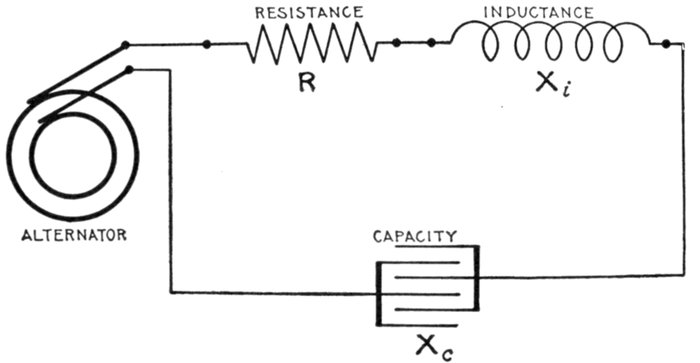

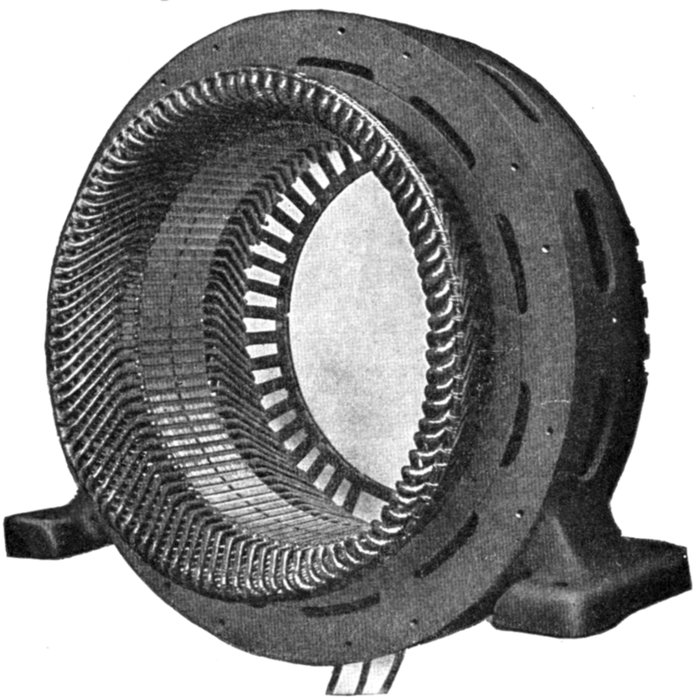

Ohmic Value of Inductance.—The rate of change of an

alternating current at any point expressed in degrees is equal

to the product of 2π multiplied by the frequency, the maximum

current, and the cosine of the angle of position θ; that is (using

symbols)

rate of change = 2πfImaxcos θ.

The numerical value of the rate of change is independent of

its positive or negative sign, so that the sign of the cos φ is

disregarded.

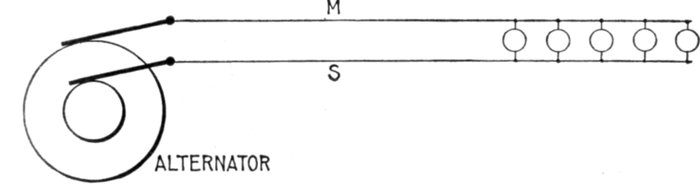

Fig. 1,276.—Inductance experiment with intermittent direct current. A lamp S is connected

in parallel with a coil of fairly fine wire having a removable iron core, and the terminals

T, T' connected to a source of direct current, a switch M being provided to interrupt the

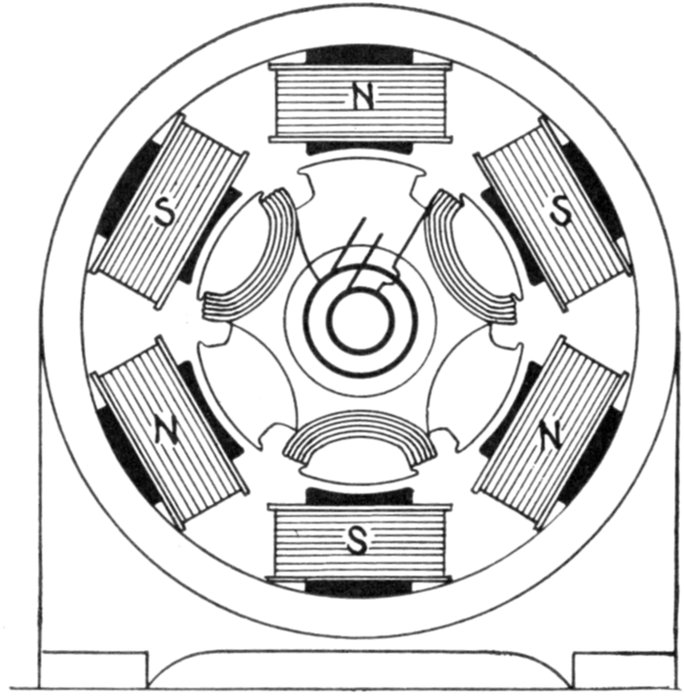

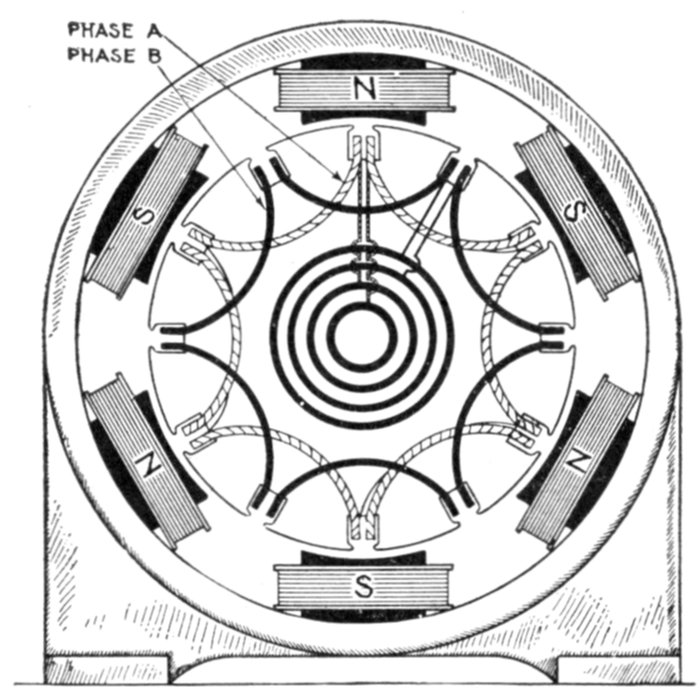

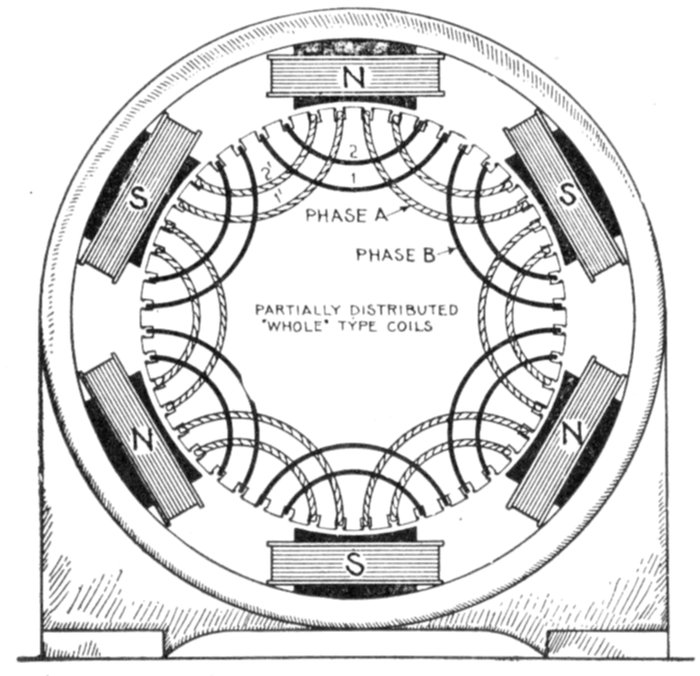

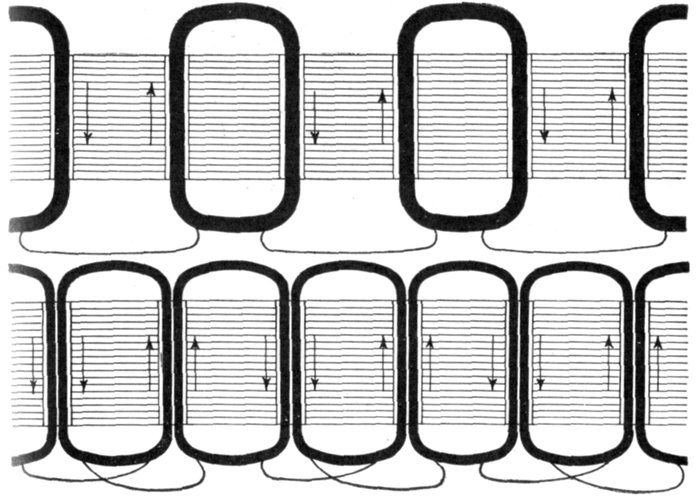

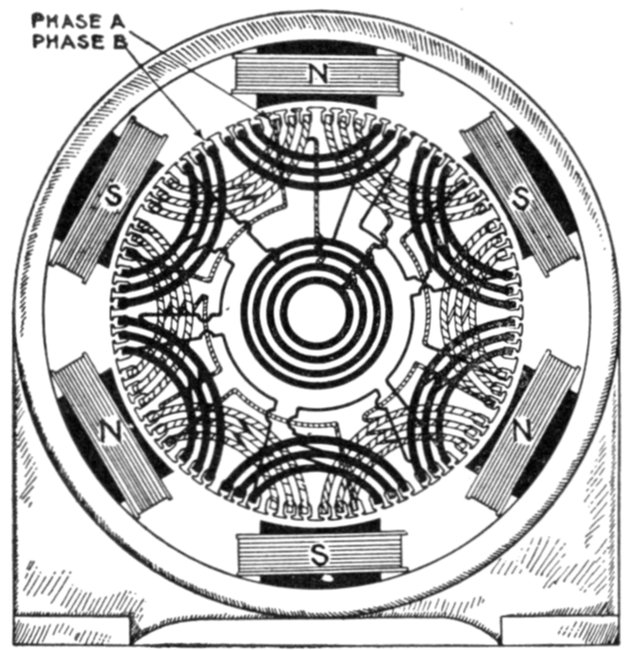

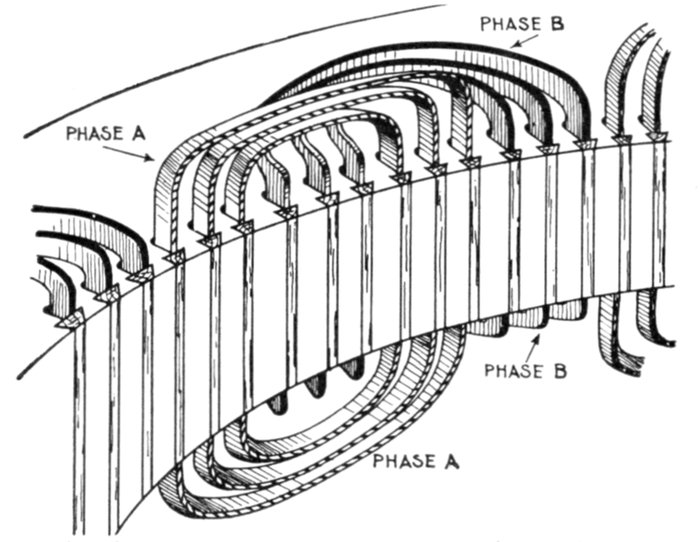

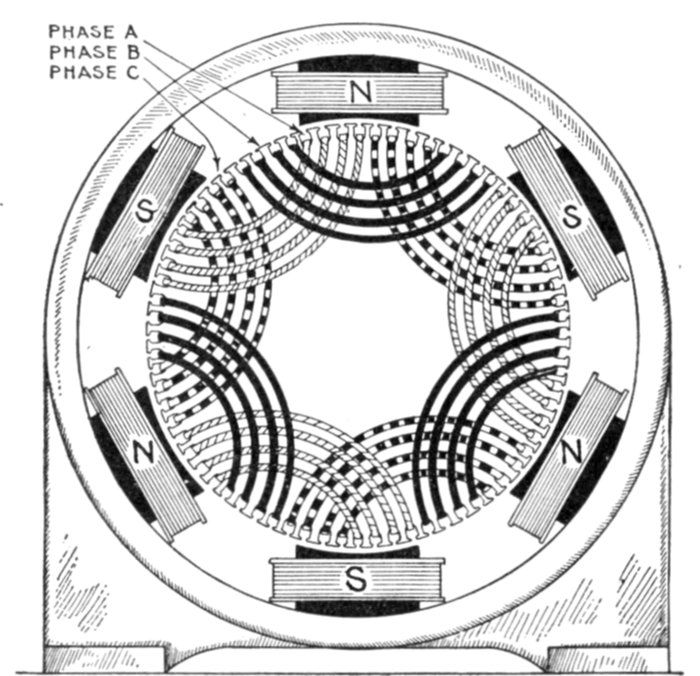

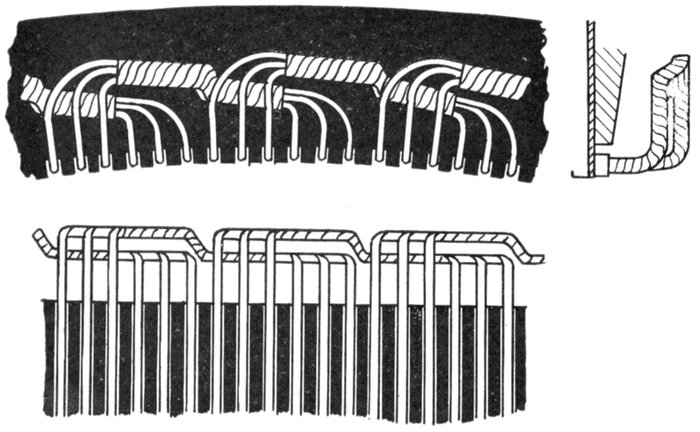

current. The voltage of the current and resistance of the coil are of such values that when

a steady current is flowing, the lamp filament is just perceptibly red. At the instant of

making the circuit, the lamp will momentarily glow more brightly than when the current is

steady; on breaking the circuit the lamp will momentarily flash with great brightness. In the

first case, the reverse pressure, due to inductance, as indicated by arrow b, will momentarily

oppose the normal pressure in the coil, so that the voltage at the lamp will be momentarily

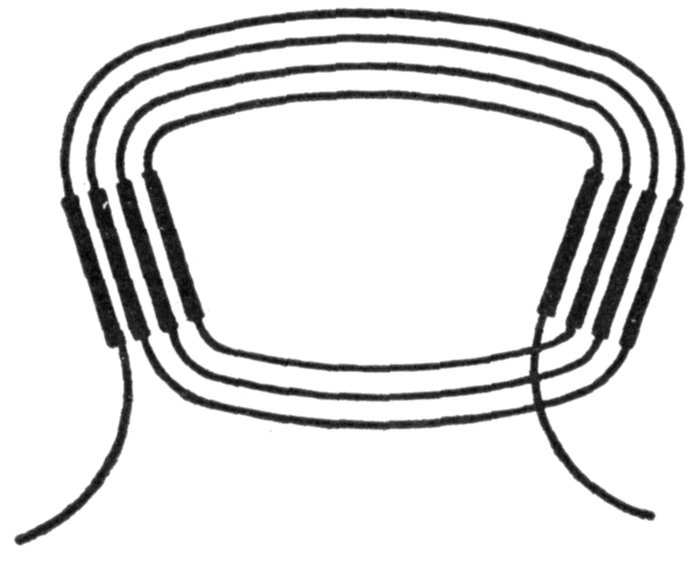

increased, and will consequently send a momentarily stronger current through the

lamp. On breaking the main circuit at M, the field of the coil will collapse, generating a

momentary much greater voltage than in the first instance, in the direction of arrow a,

the lamp will flash up brightly in consequence.

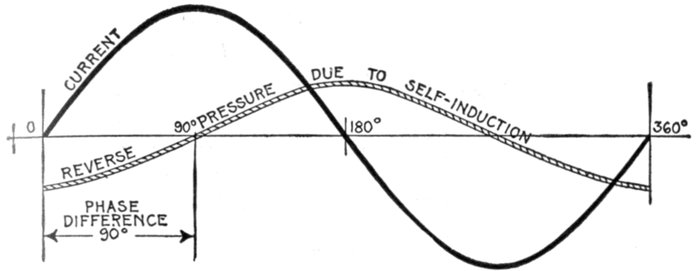

The period of greatest rate of change is that at which cos φ

has the greatest value, and the maximum value of a cosine is

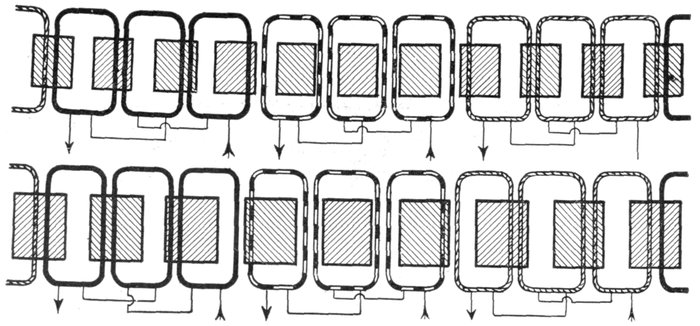

when the arc has a value of zero degrees or of 180 degrees, its

value corresponding, being 1. (See fig. 1,037, page 1,068.)

The pressure due to inductance is equal to the product of the

rate of change by the inductance; that is, calling the inductance L,[Pg 1038]

the pressure due to it at the point of maximum value or

Emax = 2πfImax × L (1)

Now by Ohm's law

Emax = RImax (2)

for a current Imax, hence substituting equation (2) in equation (1)

RImax = 2πfImax × L

from which, dividing both sides by Imax, and using Xi for R

Xi = 2πfL (3)

which is the ohmic equivalent of inductance.

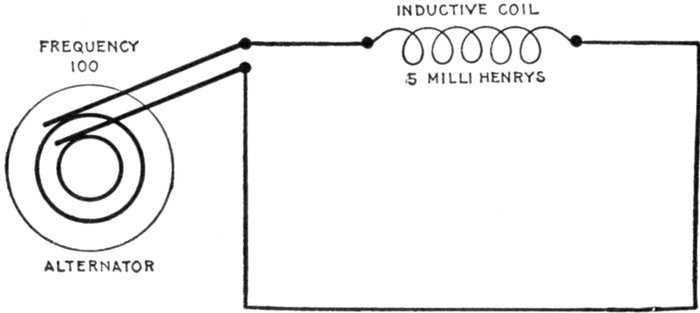

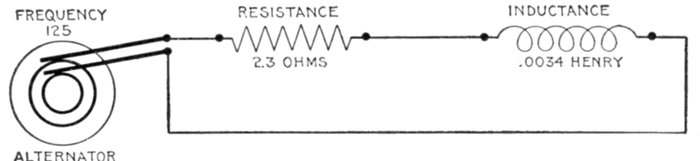

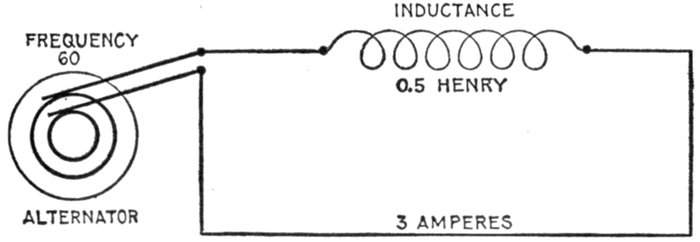

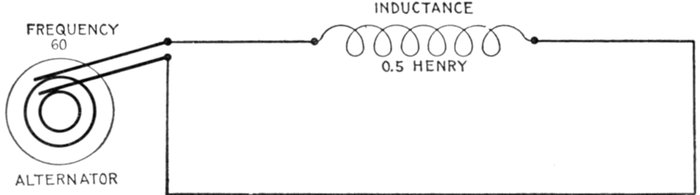

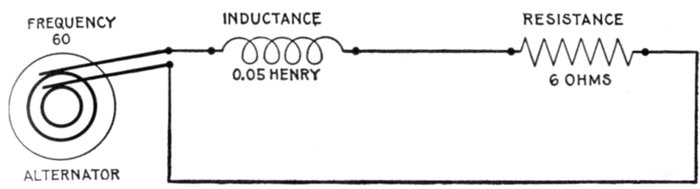

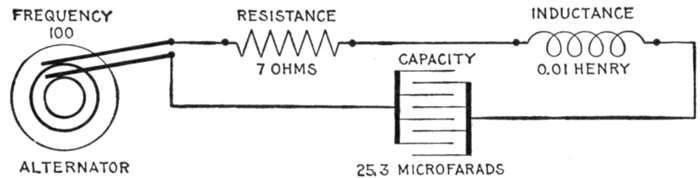

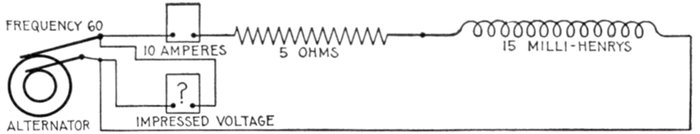

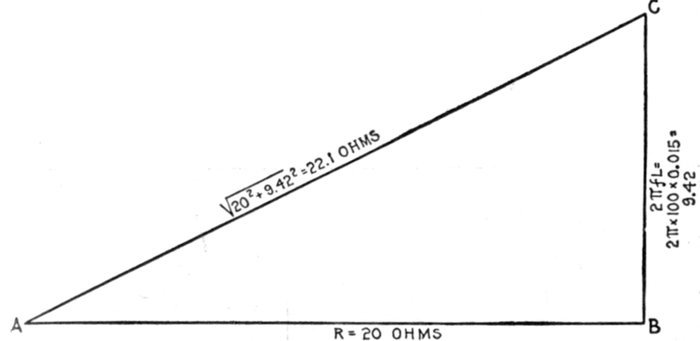

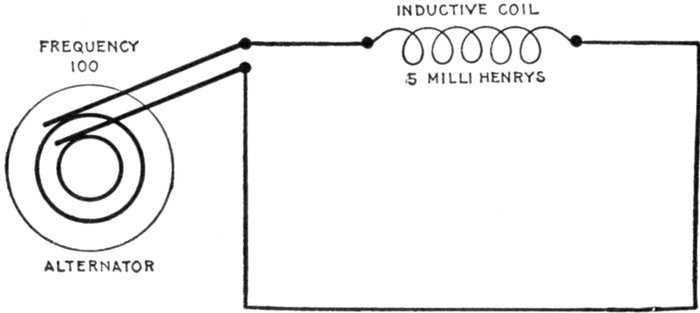

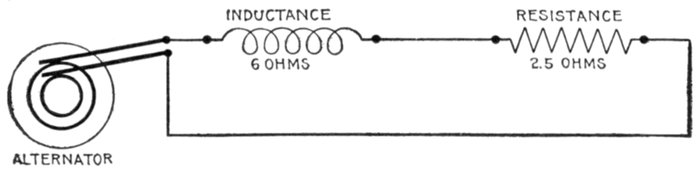

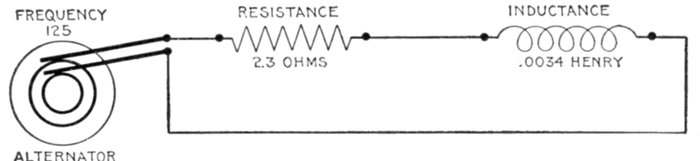

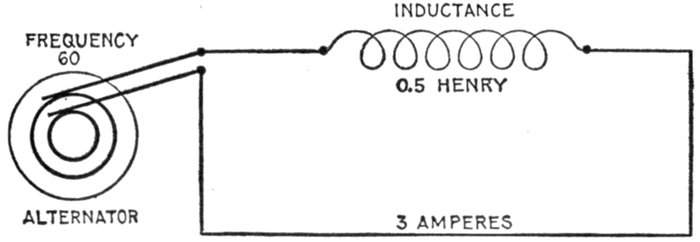

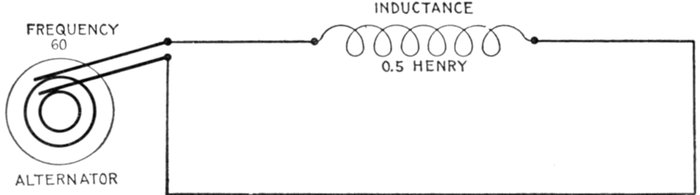

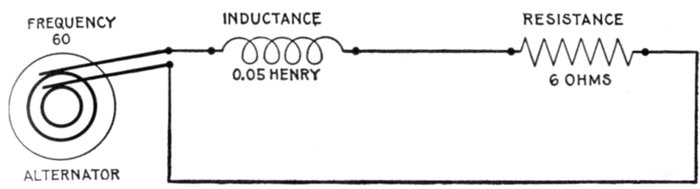

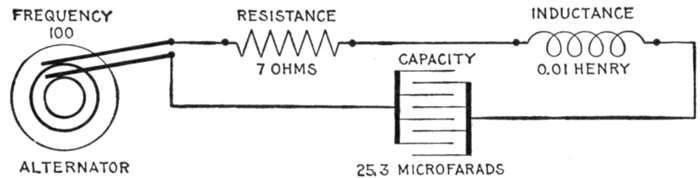

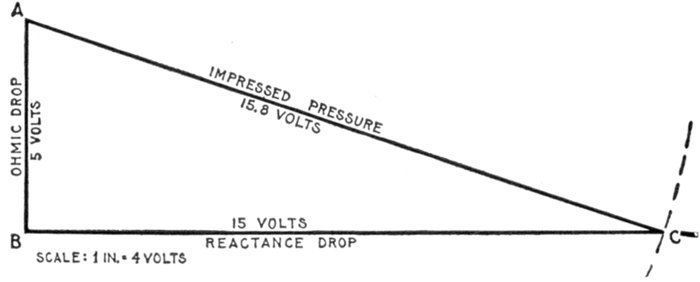

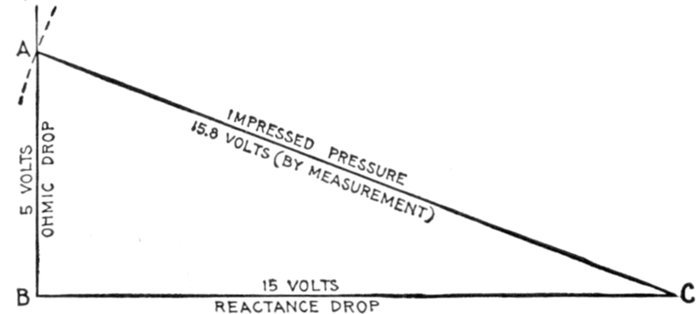

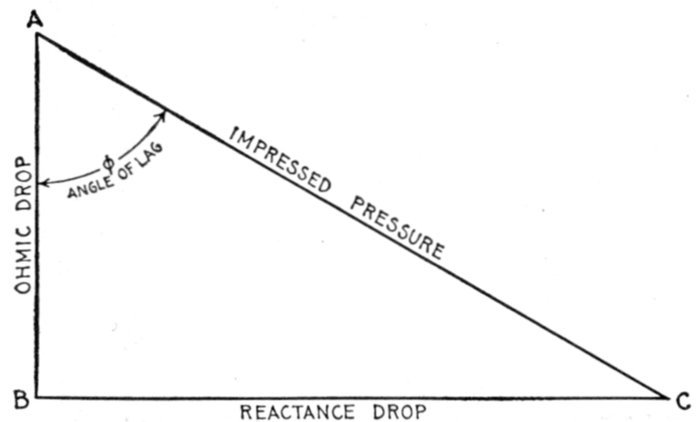

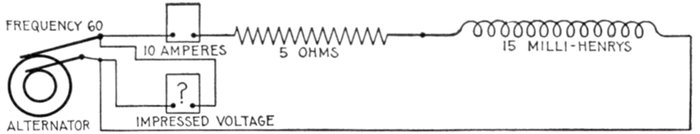

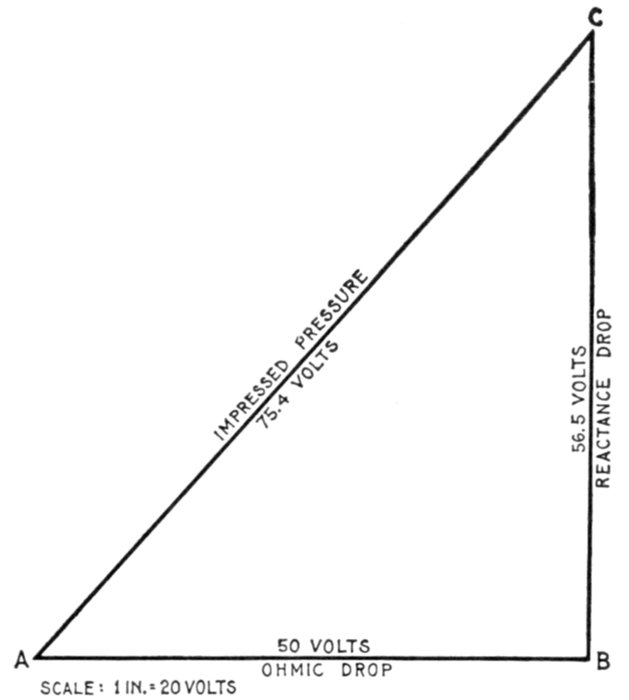

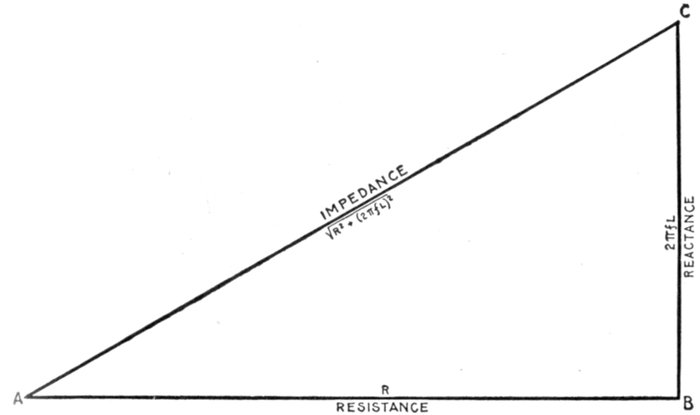

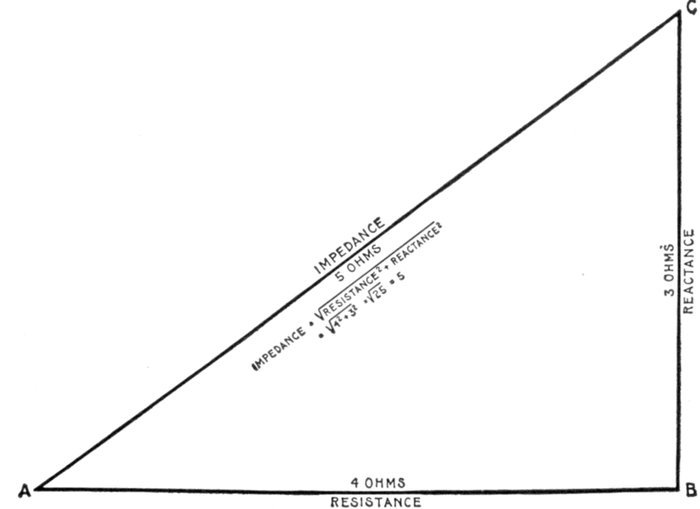

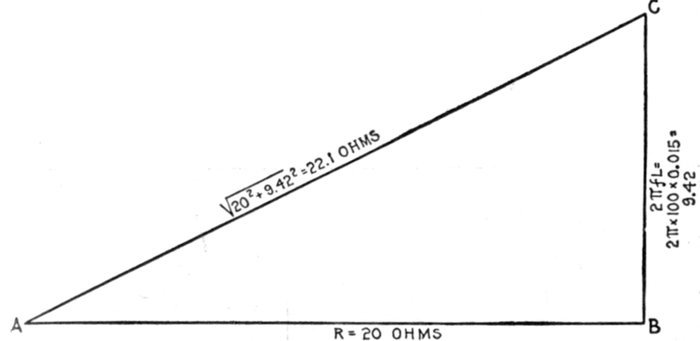

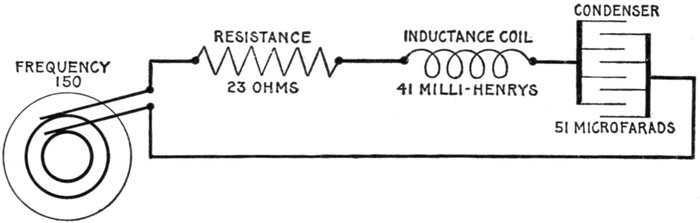

FIG. 1,277.—Diagram showing alternating circuit containing inductance. Formula for calculating

the ohmic value of inductance or "inductance reactance," is Xi = 2πfL in which

Xi = inductance reactance; π = 3.1416; f = frequency; L = inductance in henrys (not

milli-henrys). L = 15 milli-henrys = 15 ÷ 1000 = .015 henrys. Substituting, Xi = 2 ×

3.1416 × 100 × .015 = 9.42 ohms.

The frequency of a current being the number of periods or

waves per second, then, if T = the time of a period, the frequency[Pg 1039]

of a current may be obtained by dividing 1 second by the time

of a period; that is

substituting 1 / T for f in equation (3)

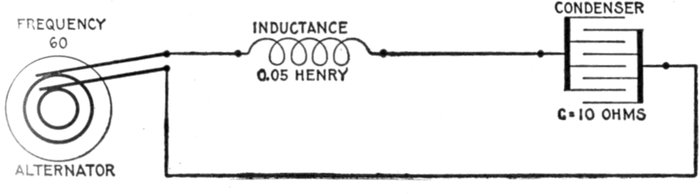

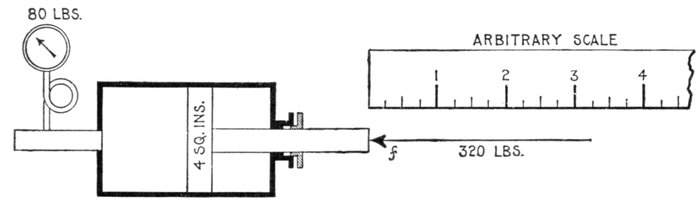

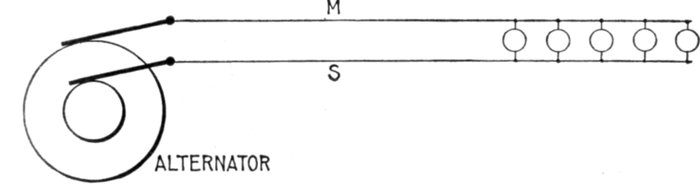

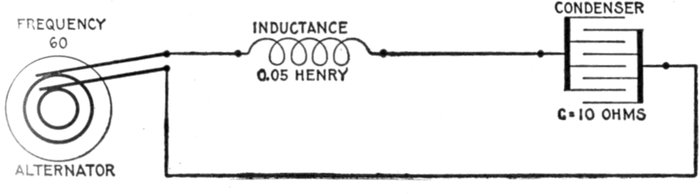

Fig. 1,278.—- Diagram illustrating effect of capacity in an alternating circuit. Considering its

action during one cycle of the current, the alternator first "pumps," say from M to S;

electricity will be heaped up, so to speak, on S, and a deficit left on M, that is, S will be

+ and M-. If the alternator be now suddenly stopped, there would be a momentary

return flow of electricity from S to M through the alternator. If the alternator go on

working, however, it is obvious that the electricity heaped up on S helps or increases the

flow when the alternator begins to pump from S to M in the second half of the cycle, and

when the alternator again reverses its pressure, the + charge on M flows round to S, and

helps the ordinary current. The above circuit is not strictly analogous to the insulated

plates of a condenser, but, as is verified in practice, that with a rapidly alternating pressure,

the condenser action is not perceptibly affected if the cables be connected across by

some non-inductive resistance as for instance incandescent lamps.

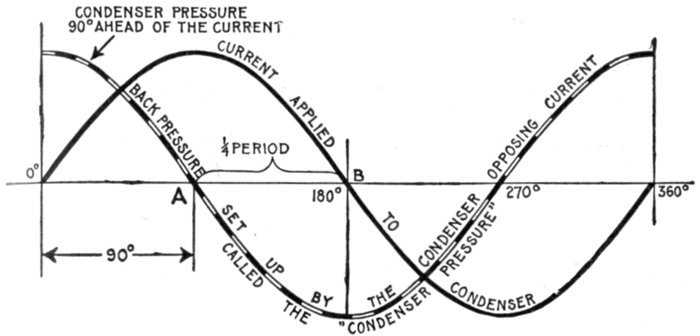

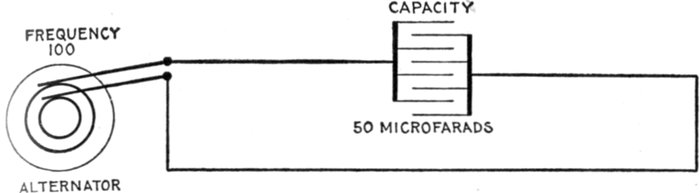

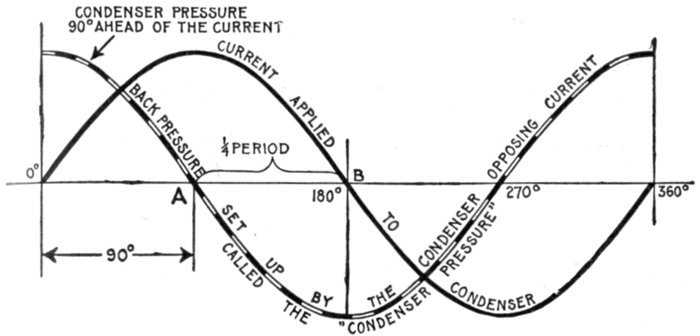

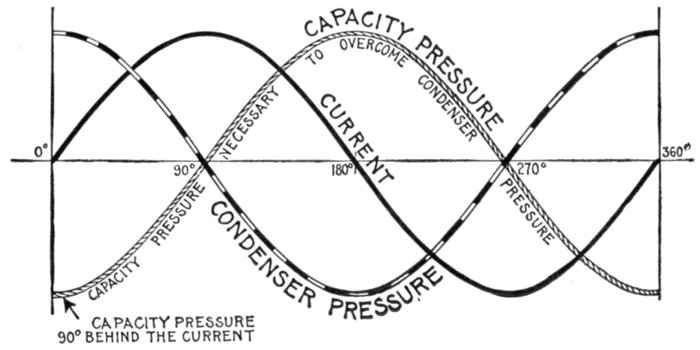

Capacity.—When an electric pressure is applied to a condenser,

the current plays in and out, charging the condenser in

alternate directions. As the current runs in at one side and out

at the other, the dielectric becomes charged, and tries to discharge

itself by setting up an opposing electric pressure. This

opposing pressure rises just as the charge increases.

A mechanical analogue is afforded by the bending of a spring,

as in fig. 1,279, which, as it is being bent, exerts an opposing force[Pg 1040]

equal to that applied, provided the latter do not exceed the

capacity of the spring.

Ques. What is the effect of capacity in an alternating

circuit?

Ans. It is exactly opposite to that of inductance, that is,

it assists the current to rise to its maximum value sooner than

it would otherwise.

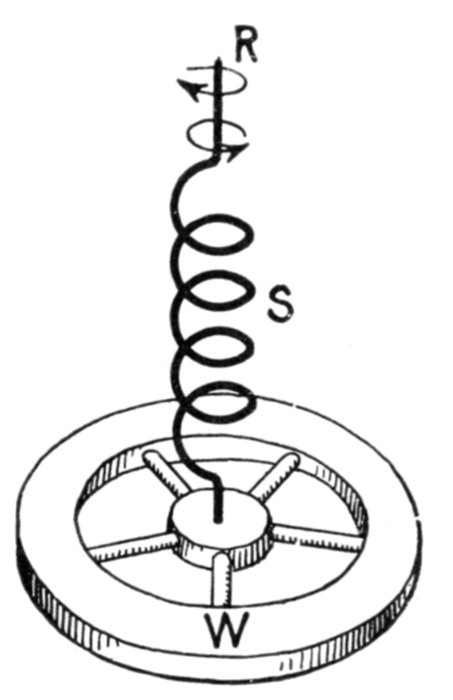

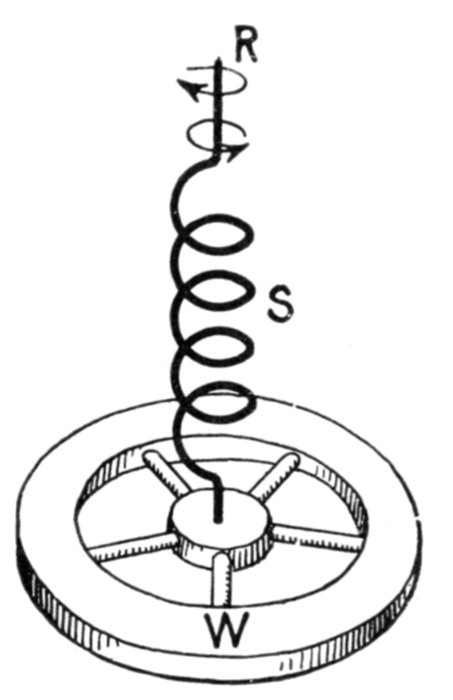

Fig. 1,279.—Mechanical analogy illustrating effect of capacity in an alternating circuit. If an

alternating twisting force be applied to the top R of the spring S, the action of the latter

may be taken to represent capacity, and the rotation of the wheel W, alternating current.

The twisting force (impressed pressure) must first be applied before the rotation of W

(current) will begin. The resiliency or rebounding effect of the spring will, in time, cause

the wheel W to move (amperes) in advance of the twisting force (voltage) thus representing

the current leading in phase.

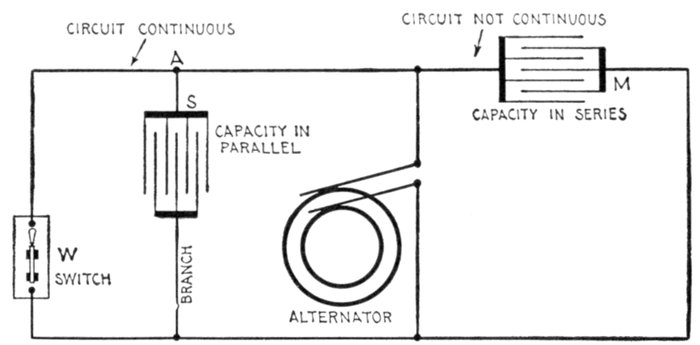

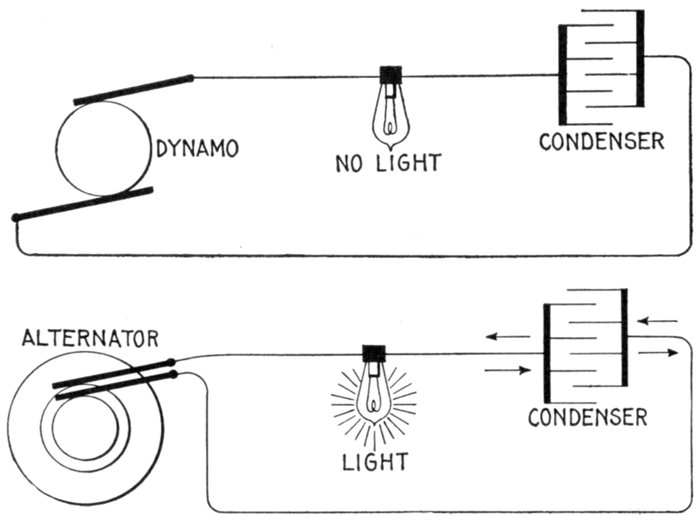

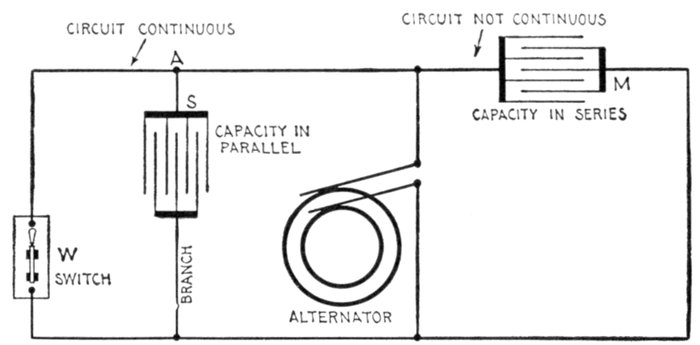

Ques. Is it necessary to have a continuous metallic

circuit for an alternating current?

Ans. No, it is possible for an alternating current to flow

through a circuit which is divided at some point by insulating

material.

[Pg 1041]

Ques. How can the current flow under such condition?

Ans. Its flow depends on the capacity of the circuit and

accordingly a condenser may be inserted in the circuit as in

fig. 1,286, thus interposing an insulated gap, yet permitting an

alternating flow in the metallic portion of the circuit.

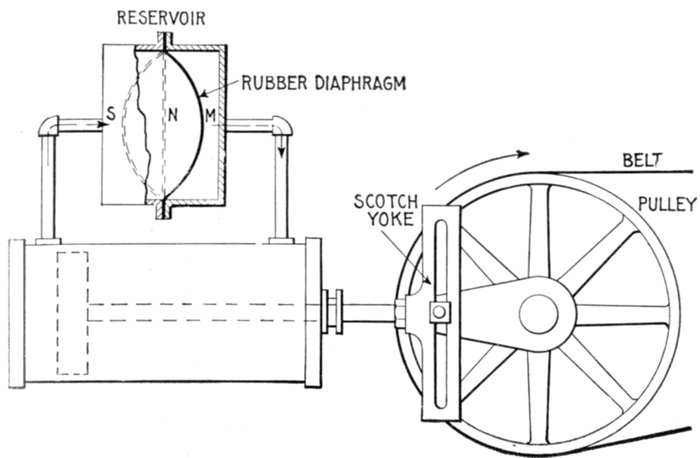

Fig. 1,280.—Hydraulic analogy illustrating capacity in an alternating current circuit. A

chamber containing a rubber diaphragm is connected to a double acting cylinder and the

system filled with water. In operation, as the piston moves, say to the left from the

center, the diaphragm is displaced from its neutral position N, and stretched to some

position M, in so doing offering increasing resistance to the flow of water. On the

return stroke the flow is reversed and is assisted by the diaphragm during the first half

of the stroke, and opposed during the second half. The diaphragm thus acts with the

flow of water one-half of the time and in opposition to it one-half of the time. This

corresponds to the electrical pressure at the terminals of a condenser connected in an

alternating current circuit, and it has a maximum value when the current is zero and a

zero value when the current is a maximum.

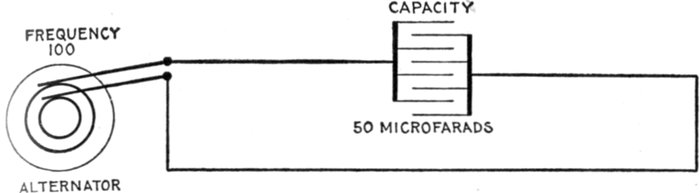

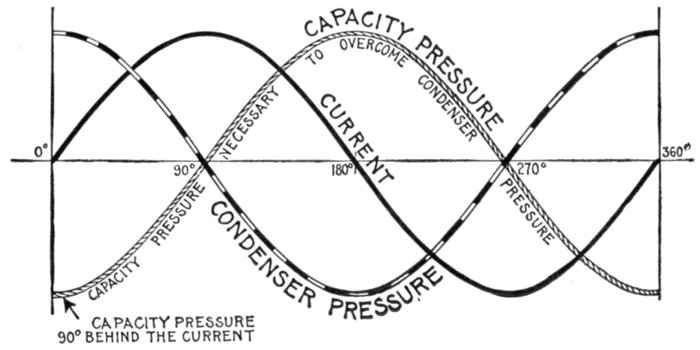

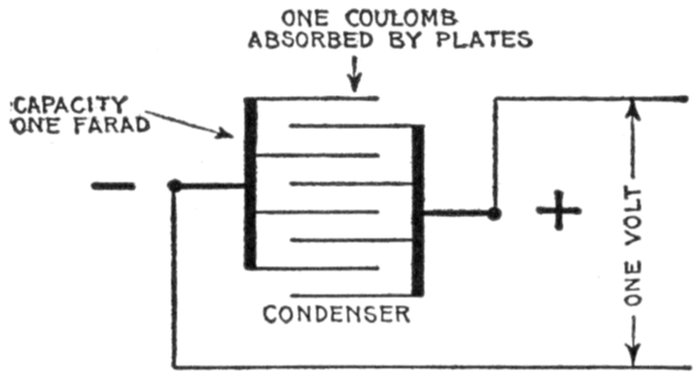

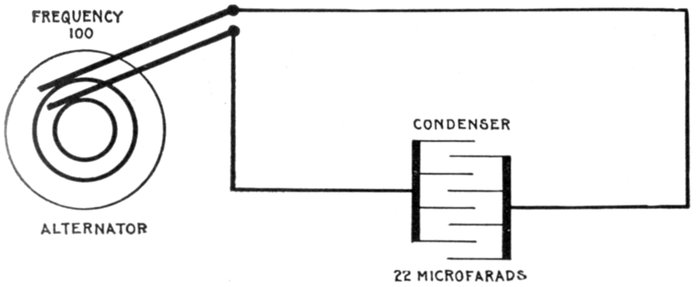

Ques. Name the unit of capacity and define it.

Ans. The unit of capacity is called the farad and its symbol is

C. A condenser is said to have a capacity of one farad if one

coulomb (that is, one ampere flowing one second), when stored[Pg 1042]

on the plates of the condenser will cause a pressure of one volt

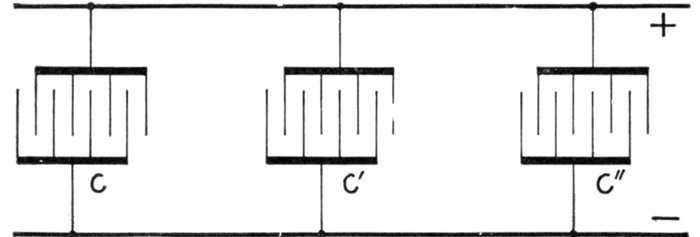

across its terminals.

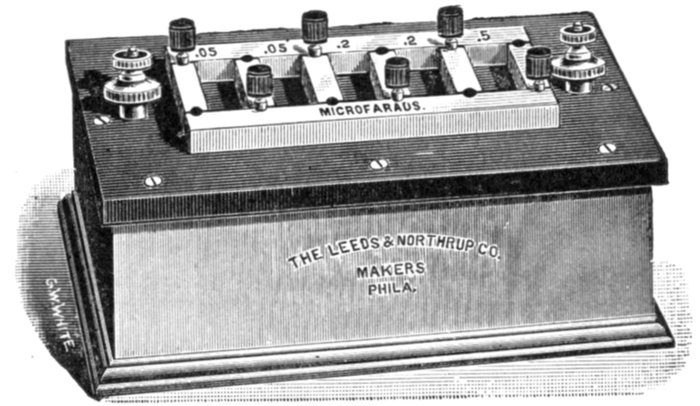

The farad being a very large unit, the capacities ordinarily encountered

in practice are expressed in millionths of a farad, that is, in microfarads--a

capacity equal to about three miles of an Atlantic cable.

It should be noted that the microfarad is used only for convenience,

and that in working out problems, capacity should

always be expressed in farads before substituting in formulæ,

because the farad is chosen with respect to the volt and ampere,

as above defined, and hence must be used in formulæ along with

these units.

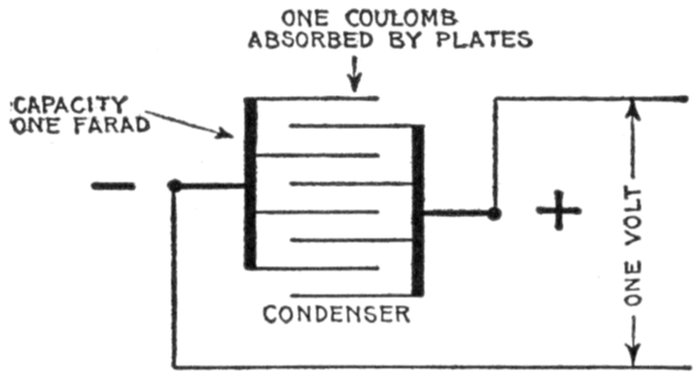

Fig. 1,281—Diagram illustrating a farad. A condenser is said to have a capacity of one

farad if it will absorb one coulomb of electricity when subjected to a pressure of one volt.

The farad is a very large unit, and accordingly the microfarad or one millionth of a farad

is often used, though this must be reduced to farads before substituting in formulæ.

For instance, a capacity of 8 microfarads as given in a problem would

be substituted in a formula as .000008 of a farad.

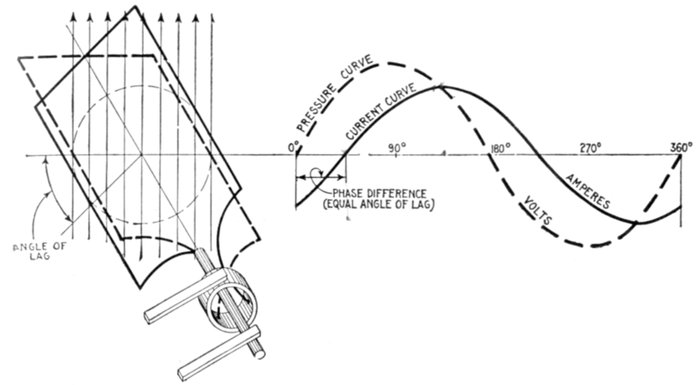

The charge Q forced into a condenser by a steady electric

pressure E is

Q = EC

in which

- Q = charge in coulombs;

- E = electric pressure in volts;

[Pg 1043]

- C = capacity of condenser in farads.

Ques. What is the material between the plates of a

condenser called?

Ans. The dielectric.

Ques. Upon what does the capacity of a condenser

depend?

Ans. It is proportional to the area of the plates, and inversely

proportional to the thickness of the dielectric between the

plates, a correction being required unless the thickness of dielectric

be very small as compared with the dimensions of the plates.

The capacity of a condenser is also proportional to the specific inductive

capacity of the dielectric between the plates of the condenser.

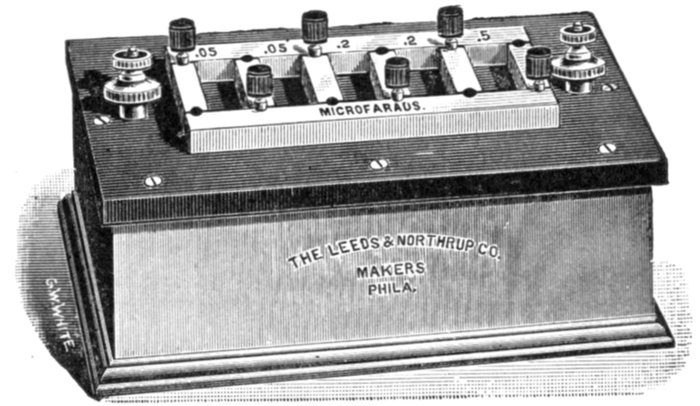

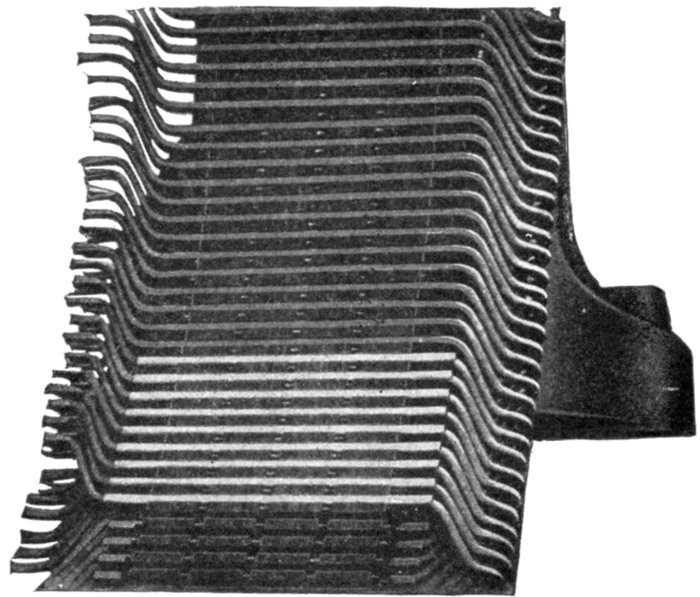

Fig. 1,282.—Condenser of one microfarad capacity. It is subdivided into five sections

of .5, .2, .2, .05 and .05 microfarad. The plates are mounted between and carried by lateral

brass bars which are fastened to a hard rubber top. Each pair of condenser terminals

is fastened to small binding posts mounted on hard rubber insulated posts.

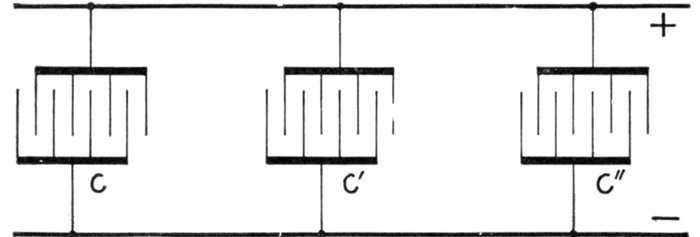

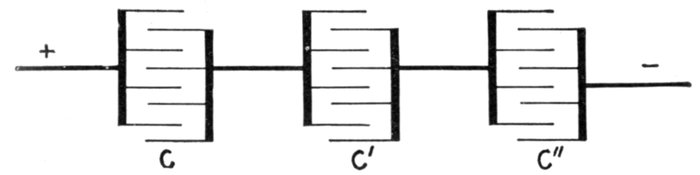

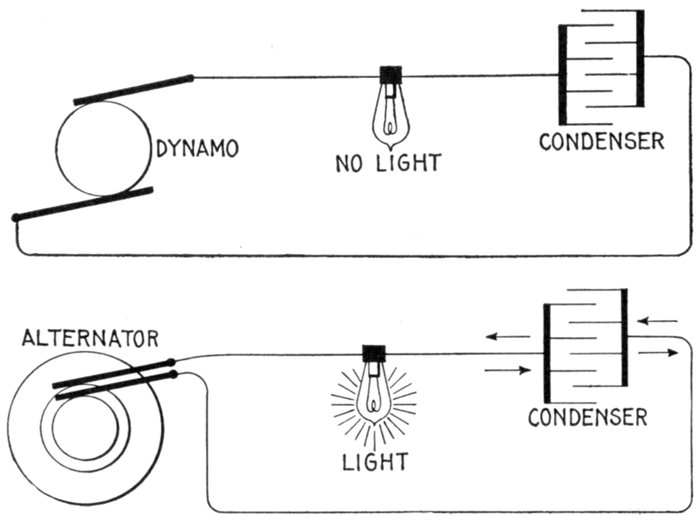

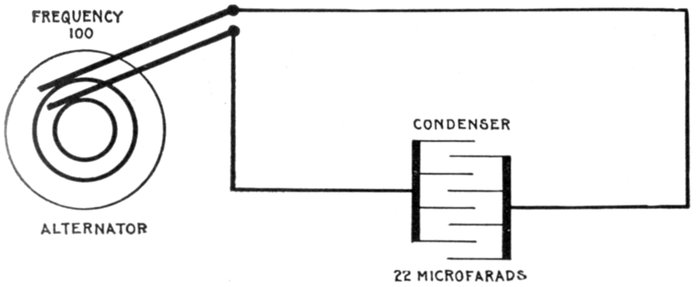

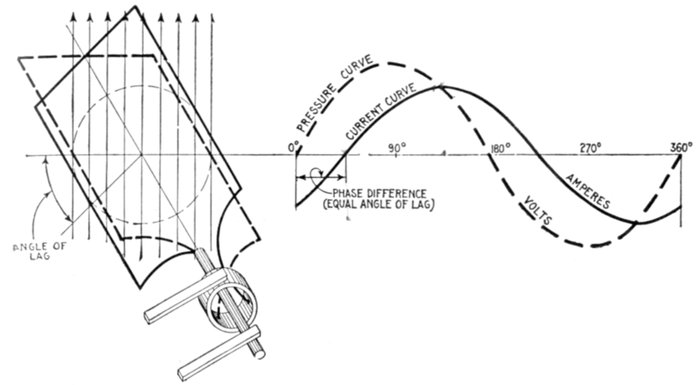

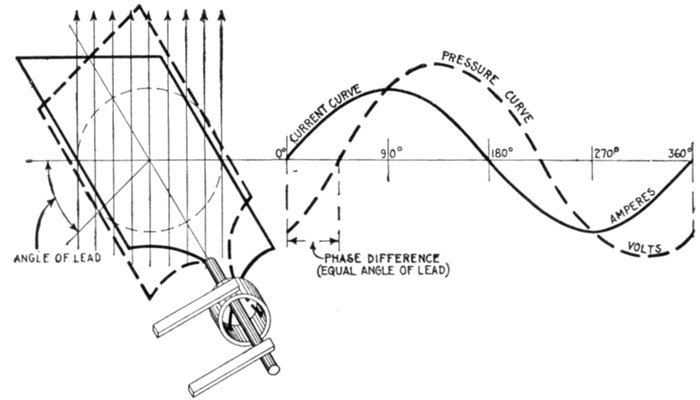

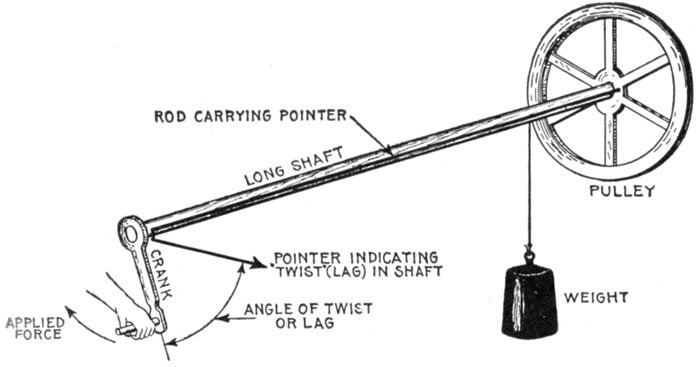

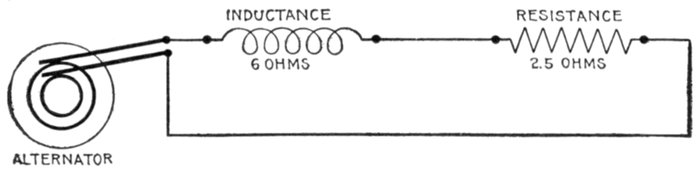

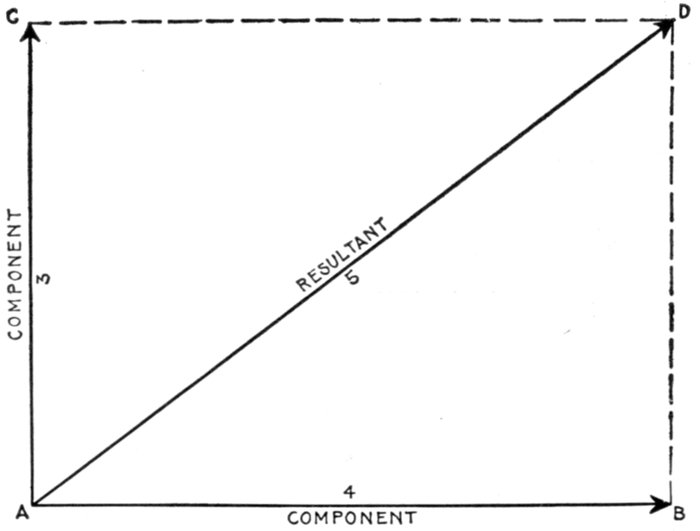

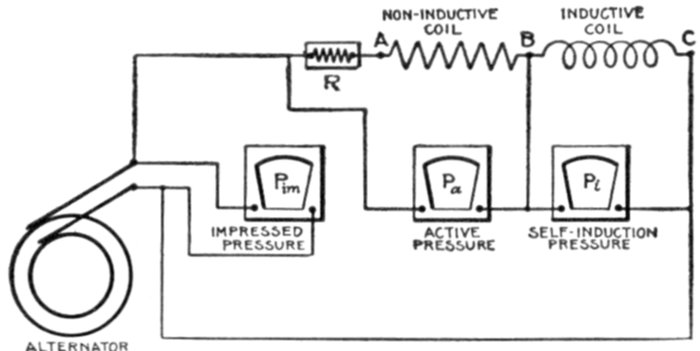

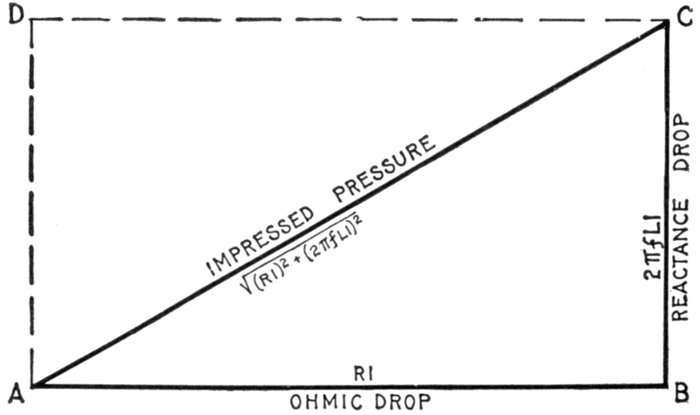

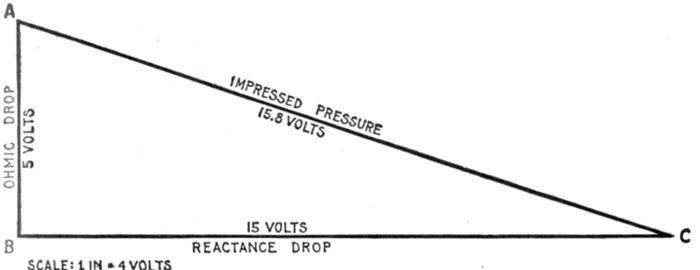

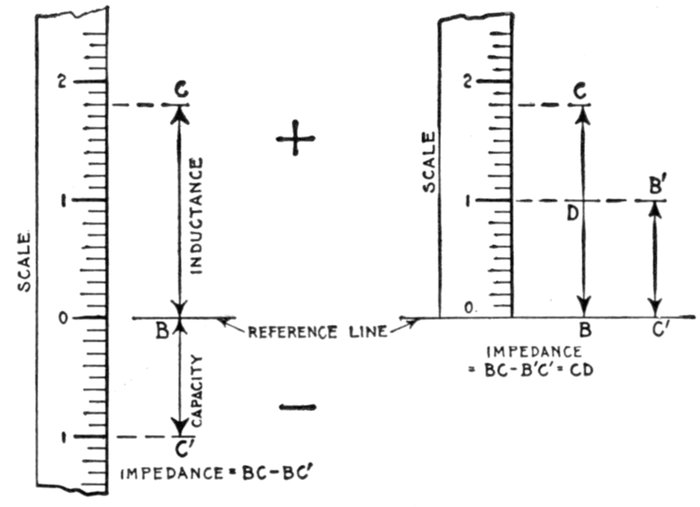

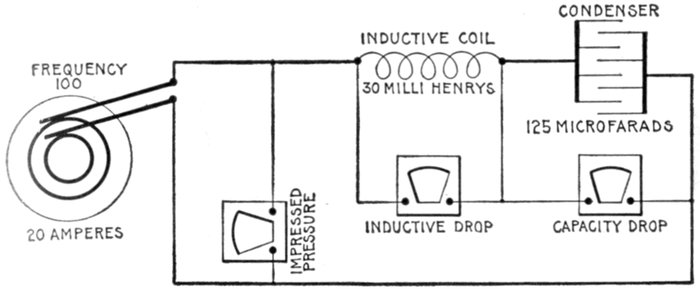

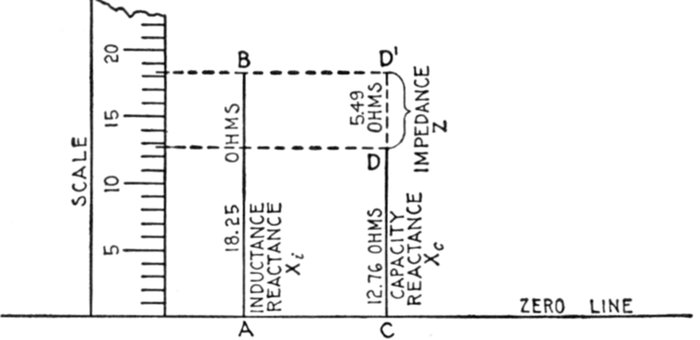

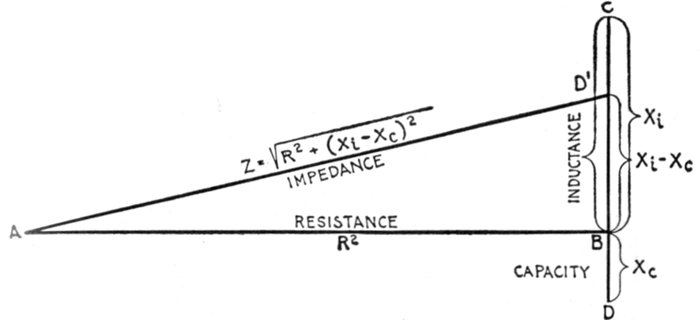

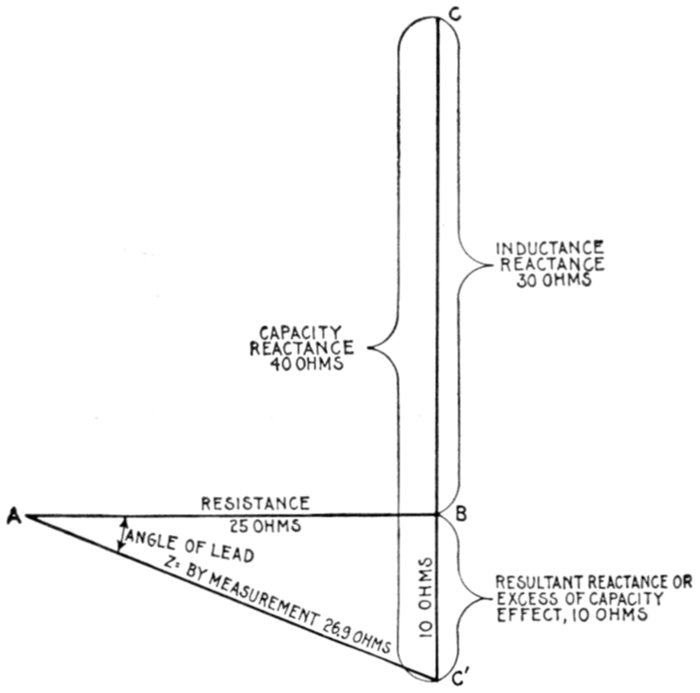

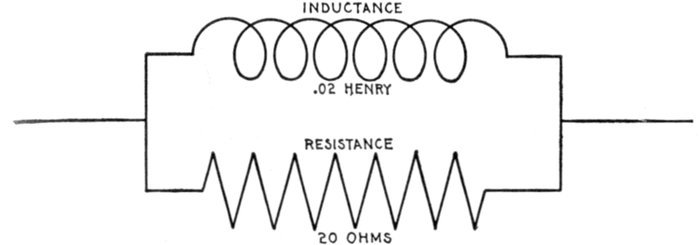

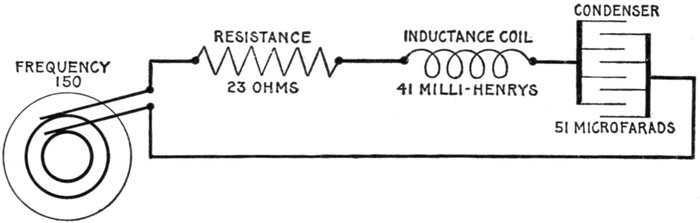

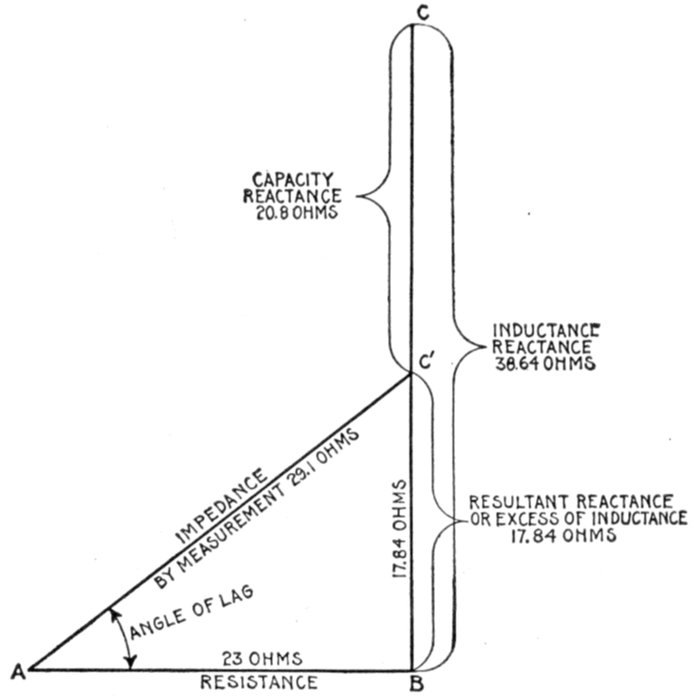

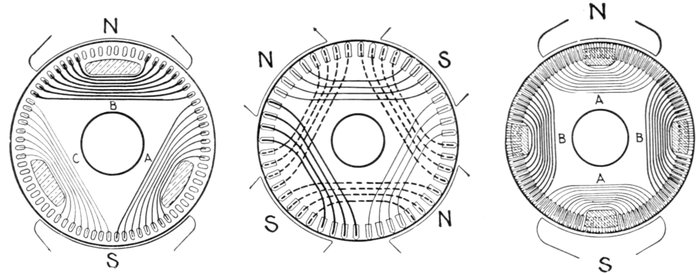

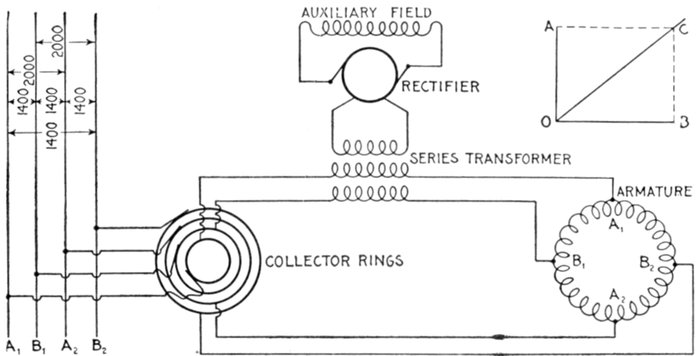

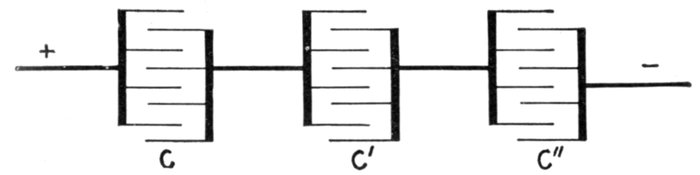

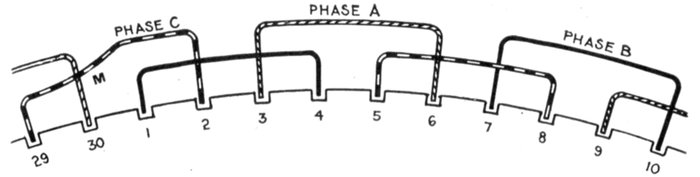

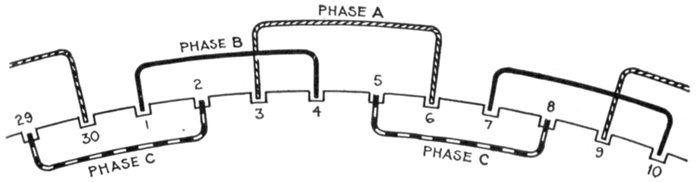

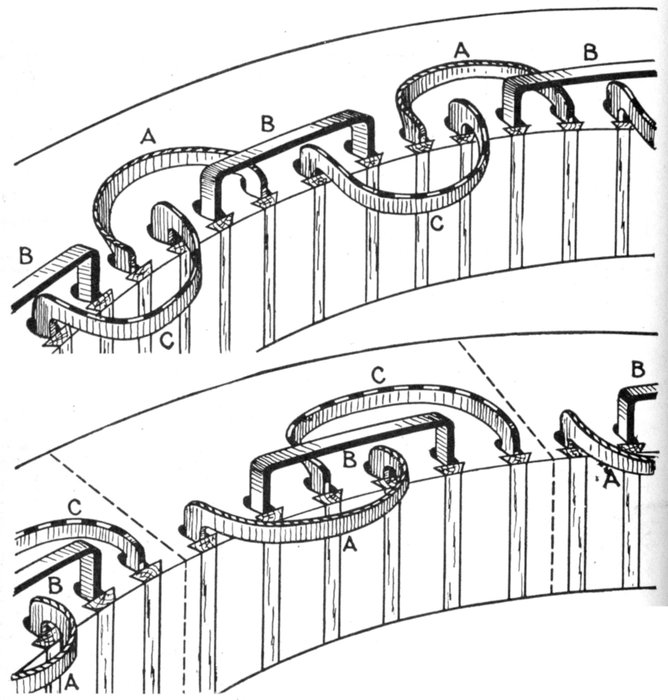

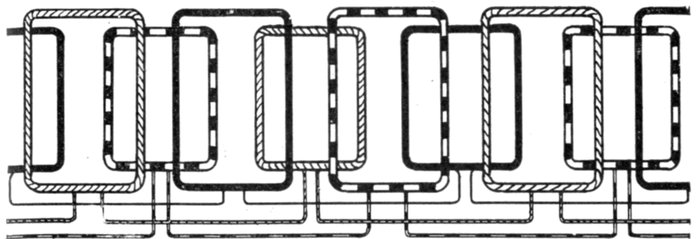

Specific Inductive Capacity.—Faraday discovered that